Durable Plastic Flexible Cable Carrier Chains for Efficient Cable Management Solutions

Understanding Plastic Flexible Cable Carrier Chains

In today’s fast-paced industrial environment, the need for efficiency and reliability in machinery operation has never been more critical. One essential component that plays a vital role in achieving these objectives is the plastic flexible cable carrier chain. These innovative solutions are designed to manage and protect cables and hoses in dynamic applications, ensuring that equipment runs smoothly and safely.

What is a Plastic Flexible Cable Carrier Chain?

A plastic flexible cable carrier chain, often referred to simply as a cable chain or energy chain, is a modular system used to guide and protect flexible cables and hoses used in moving machinery. The design typically consists of interconnected links that create a flexible conduit, allowing the cables or hoses to move freely while being shielded from abrasion, kinks, and other potential damages.

These chains are made primarily from high-performance plastics, which give them several advantages over traditional metal chain systems. The lightweight nature of plastic reduces the overall load on machinery, enhances energy efficiency, and minimizes wear and tear on moving parts.

Key Features and Advantages

1. Lightweight and Durable The use of plastic in cable carrier chains significantly reduces their weight compared to metal alternatives. This feature is crucial in applications where weight may impact the performance of machines, leading to increased efficiency and reduced energy consumption.

2. Flexibility Plastic cable carrier chains are designed to handle multiple bending cycles without breaking. Their flexibility allows them to adapt to varying movement patterns in applications ranging from robotics to CNC machines, ensuring that fluidity and motion are maintained.

3. Low Friction Many plastic materials offer reduced friction compared to metal, which results in less wear on cables and hoses and extends their lifespan. This characteristic is particularly useful in high-speed applications where friction can lead to premature failure.

4. Corrosion Resistance Unlike metal, plastic cable carriers are resistant to corrosive substances and environmental conditions. This resilience ensures that they remain functional in harsh environments, such as those found in chemical processing or outdoor applications.

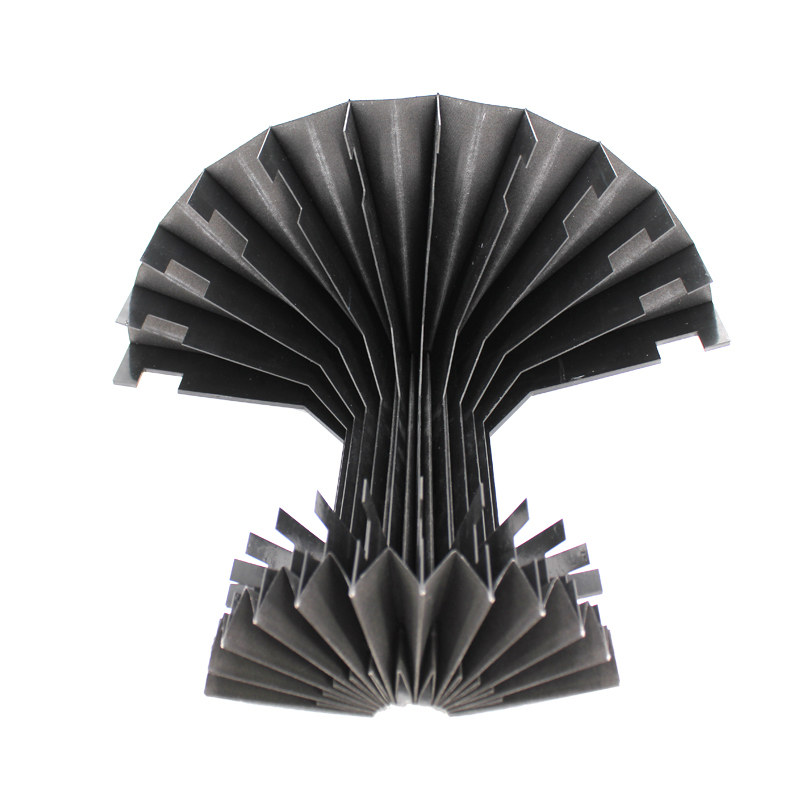

plastic flexible cable carrier chain

5. Noise Reduction The use of plastic can help to dampen noise levels produced by machinery. This feature contributes to a quieter working environment, which can improve worker comfort and productivity.

6. Easy Installation and Maintenance Plastic cable carrier chains are designed with ease of installation in mind. The modular design allows for quick assembly and disassembly, which is particularly beneficial during maintenance or when modifications are required.

Applications

Plastic flexible cable carrier chains are utilized in a multitude of industries and applications. Some common uses include

- Automation and Robotics In automated systems and robotics, cable chains help to maintain the integrity of power and data lines as machinery moves. - CNC Machining Cable carriers manage the cables that power cutting tools and motors, ensuring they remain organized and protected from damage. - Material Handling Equipment In conveyors and other material handling systems, these chains provide a secure pathway for cables and hoses, reducing the risk of entanglement.

- Packaging Machines Ensuring that machinery operates smoothly during the rapid movement of packaging materials is another critical application for these cable management systems.

- Lift Systems In lift applications, the consistent movement of cables and hoses can be efficiently managed using flexible cable carrier chains, ensuring safety and reliability.

Conclusion

Plastic flexible cable carrier chains are an essential innovation in the realm of industrial machinery. Their unique features—such as lightweight construction, flexibility, low friction, and resistance to corrosion—make them a superior choice for protecting and managing cables and hoses in motion. As industries continue to advance towards greater automation and efficiency, the role of plastic cable carrier chains will undoubtedly become more prominent, ensuring that machinery operates effectively while minimizing the risk of damage and downtime. Future developments in materials and designs will further enhance their capabilities, solidifying their place as a critical component in modern industrial applications.