plastic drag chain cable carrier

Understanding Plastic Drag Chain Cable Carriers

In today's industrial landscape, the efficient management of power and data cables is crucial for the smooth operation of various machinery and equipment. One of the most effective solutions for this purpose is the plastic drag chain cable carrier, a versatile component designed to protect and guide cables in motion.

What is a Drag Chain Cable Carrier?

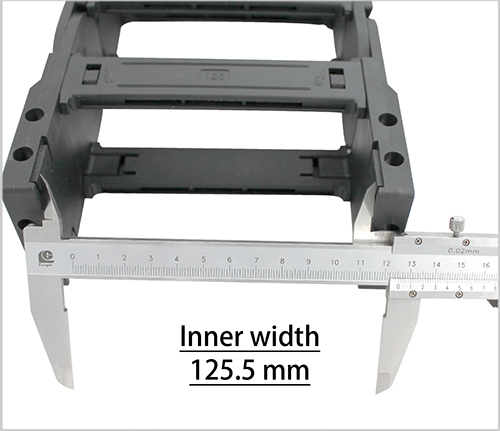

A drag chain cable carrier, also known as a cable track, is an essential device used in automated machinery. It consists of interconnected links that form a channel through which cables and hoses can move freely. The drag chain allows for smooth and controlled movement, ensuring that cables do not become tangled or strained during operation.

Benefits of Plastic Construction

The choice of material significantly impacts the performance and durability of cable carriers. Plastic drag chains are increasingly popular due to their lightweight nature and resistance to various environmental factors. Unlike metal alternatives, plastic drag chains are less prone to corrosion, making them ideal for humid or corrosive environments. Furthermore, plastic carriers often come with a lower coefficient of friction, allowing for quieter and smoother operation.

- Weight Reduction Plastic drag chains are significantly lighter than metal ones, reducing the overall weight of the machinery. This weight reduction allows for greater flexibility in designs and can lead to lower energy consumption during operation.

- Cost-Effectiveness Plastic materials tend to be cheaper than metals, which helps lower the overall cost of production and maintenance. Their durability also translates into less frequent replacements, thereby reducing long-term operational costs.

plastic drag chain cable carrier

- Noise Reduction The inherent properties of plastic allow for quieter operation, which is beneficial in environments where noise reduction is a priority

.Design Versatility

Plastic drag chains come in various designs and sizes, making them adaptable to numerous applications. They can be configured to handle various types of cables, including power, data, and pneumatic hoses. Manufacturers often provide custom designs, allowing businesses to tailor solutions specific to their operational needs.

Applications of plastic drag chain cable carriers are diverse, ranging from CNC machines, robotics, and automotive assembly lines to packaging equipment and conveyor systems. Their ability to accommodate linear and curved paths makes them even more versatile, as operators can route cables in complex layouts without sacrificing functionality.

Installation and Maintenance

Installing a plastic drag chain requires careful planning to ensure optimal performance. Proper bending radii and cable arrangement are critical to avoid excess wear on the cables and the drag chain itself. Once installed, these carriers typically require minimal maintenance, primarily comprising periodic inspections to ensure they remain free of debris and wear.

Conclusion

Plastic drag chain cable carriers offer a practical and efficient solution for managing cables and hoses in dynamic environments. Their lightweight, cost-effective, and durable nature makes them an attractive choice for a wide range of industrial applications. As technology continues to evolve, the demand for reliable cable management solutions will only grow, solidifying the role of plastic drag chain carriers in modern machinery design. By investing in these innovative components, businesses can enhance productivity, ensure safety, and improve the longevity of their equipment.