Durable Plastic Drag Chains for Efficient Cable Management Solutions

Understanding Plastic Drag Chains An Essential Component for Modern Machinery

In today's fast-paced industrial environment, efficiency and reliability in machinery are paramount. One crucial component that enhances the performance of various machines is the plastic drag chain. These ingenious devices are designed to manage and protect cables, hoses, and other flexible lines in automated systems, ensuring smooth operation and reducing wear and tear.

What are Plastic Drag Chains?

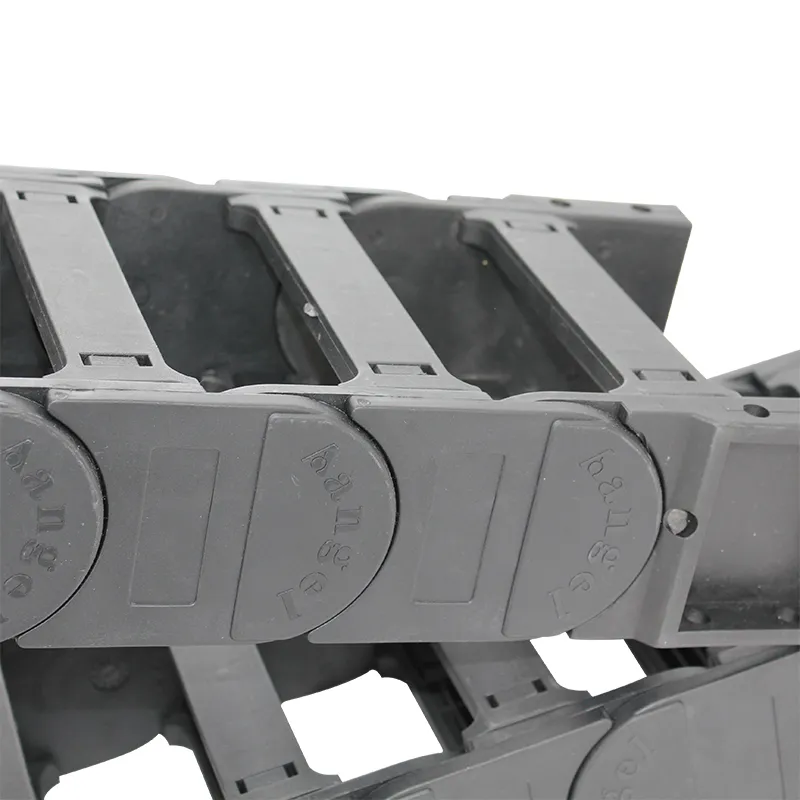

Plastic drag chains, also known as energy chains, are specifically engineered for guiding and protecting moving cables and hoses. They consist of interconnected links that form a chain-like structure, allowing them to bend and twist as needed. The primary function of these chains is to prevent tangling, abrasion, and damage to the vital components of machinery that rely on electrical and hydraulic connections.

Advantages of Using Plastic Drag Chains

One of the primary benefits of plastic drag chains is their lightweight nature compared to traditional metal chains. This attribute is particularly advantageous in applications where weight reduction is critical, such as in robotics and overhead cranes. Moreover, plastics used in fabricating drag chains often possess excellent resistance to chemicals, heat, and UV radiation, extending the lifespan of the chains and reducing maintenance costs.

Another significant advantage is the reduced friction offered by plastic drag chains. This characteristic minimizes energy consumption and enhances the performance efficiency of the machinery, leading to substantial long-term savings. Additionally, plastic drag chains offer a wide range of configurations, making them suitable for various applications, including CNC machines, conveyor systems, and automated guided vehicles (AGVs).

plastic drag chain

Applications of Plastic Drag Chains

The applications of plastic drag chains are vast and varied. In industrial automation, they are often utilized in robotic arms, allowing for fluid movement while ensuring that essential cables are securely housed. In packaging machinery, drag chains help manage cables in motion, reducing downtime caused by cable management issues.

Moreover, in the automotive sector, drag chains are employed in assembly lines to facilitate the safe movement of tools and equipment. They also find uses in wind turbines, where they protect cables and hoses from the harsh environmental conditions typical of outdoor installations. The versatility and adaptability of plastic drag chains make them indispensable across multiple industries.

Installation and Maintenance

Installing plastic drag chains is generally straightforward, as they can be customized to fit specific machinery requirements. Proper installation is crucial to ensure that the cables and hoses inside the chain are adequately secured while allowing for the necessary flexibility during operation. Regular inspection and maintenance are also essential to prevent wear and ensure longevity. Users should check for any signs of fatigue, such as cracks or excessive bending, and replace any damaged links promptly.

Conclusion

In conclusion, plastic drag chains play a vital role in enhancing the efficiency and performance of modern machinery. Their lightweight, flexible design, coupled with their ability to protect and manage cables and hoses, makes them an essential component in various industrial applications. As technology continues to evolve, the demand for innovative solutions like plastic drag chains will only increase, helping industries meet the challenges of automation and efficiency head-on. Investing in high-quality drag chains can lead to improved operational reliability and reduced maintenance costs, ultimately contributing to a more productive working environment.