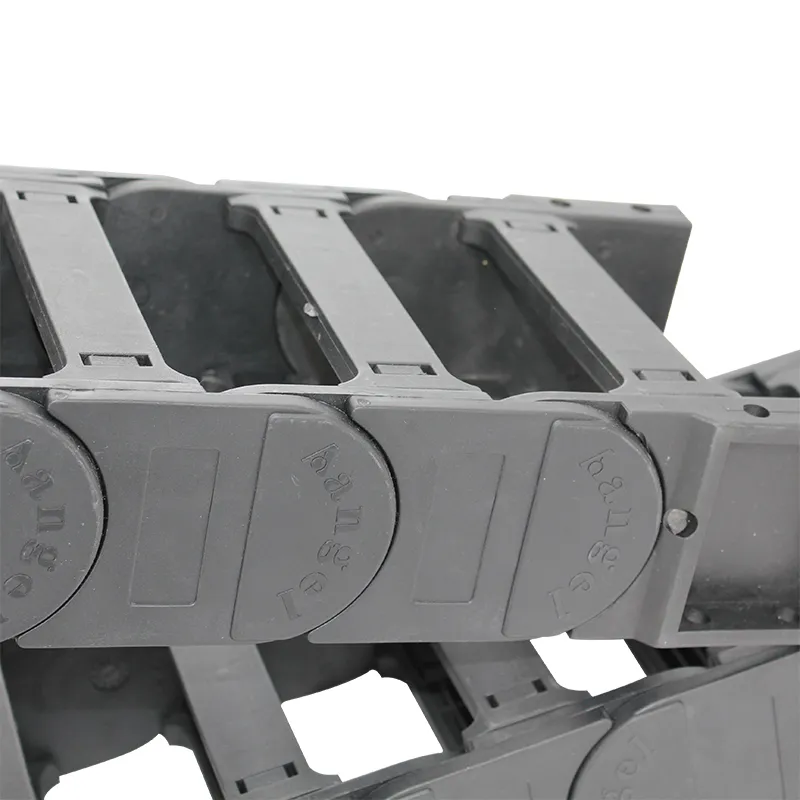

plastic drag chain

The Importance of Plastic Drag Chains in Modern Industry

In today’s fast-paced industrial environment, efficiency, safety, and reliability are paramount. As production lines become more complex, the need for innovative solutions to manage cabling and hoses has never been greater. This is where plastic drag chains come into play. Known for their versatility and durability, plastic drag chains are essential components in a variety of applications across different industries, including manufacturing, robotics, and automation.

Plastic drag chains, also referred to as cable carriers or cable tracks, are designed to house and protect cables and hoses that move with machinery. Their primary purpose is to facilitate the smooth and organized movement of these essential components, preventing tangling and wear during operation. Typically made from durable plastic materials such as nylon or polypropylene, these drag chains offer an ideal balance of strength, flexibility, and lightweight characteristics.

One of the most significant advantages of plastic drag chains is their ability to enhance operational efficiency. By organizing cables and hoses, they reduce the risk of tangling, which can lead to downtime and costly repairs. Furthermore, drag chains help mitigate wear and tear on cables and hoses, allowing for longer service life. This is particularly important in environments where machinery is subjected to repetitive movements, such as in CNC machining or conveyor systems.

plastic drag chain

In addition to operational efficiency, plastic drag chains contribute to workplace safety. Exposed cables and hoses can pose serious hazards, increasing the risk of tripping or entanglement. By effectively containing and guiding these elements, drag chains create a safer working environment. This is especially crucial in busy industrial settings where multiple operators may be working in close proximity to moving equipment.

Furthermore, plastic drag chains are adaptable to various applications. They come in a wide range of sizes and configurations, allowing for customization based on specific machinery and operational needs. Whether it’s a simple linear application or a complex multi-axis system, there is a drag chain solution that can be tailored to fit the requirements. In recent years, manufacturers have also begun to develop chains with enhanced materials that offer resistance to high temperatures, chemicals, and UV exposure, expanding their usability in harsh environments.

Another significant aspect of plastic drag chains is their ease of installation and maintenance. Many designs incorporate modular components, allowing for quick assembly and disassembly. This ease of use is advantageous for maintenance crews who require timely access to cables and hoses for repairs or upgrades. Regular maintenance can easily prolong the lifespan of both the drag chains and the cables they protect.

In conclusion, plastic drag chains are a vital element in modern industry, promoting efficiency, safety, and reliability. Their ability to protect and organize cables and hoses, coupled with their adaptability and ease of maintenance, make them an indispensable tool for manufacturers and robotic systems alike. As industries continue to evolve with advancements in technology, the role of plastic drag chains will undoubtedly grow, paving the way for smarter, safer, and more efficient operations. In an era where every second counts, investing in high-quality drag chains can lead to significant long-term benefits for any industrial operation.