plastic drag chain

Understanding Plastic Drag Chains A Comprehensive Overview

Plastic drag chains, often referred to as energy chains, are essential components in various industries, facilitating the safe and organized movement of cables and hoses. Their primary function is to protect cables and hoses from wear and tear, while ensuring they remain flexible and easy to maneuver during operation. This article delves into the intricacies of plastic drag chains, exploring their construction, benefits, and applications.

Construction and Design

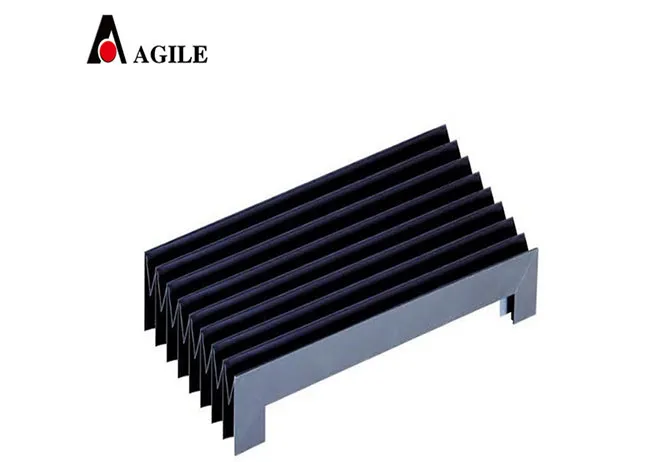

Plastic drag chains are typically made from high-quality plastic materials, such as nylon or polyamide. These materials provide the right balance of strength, flexibility, and resistance to various environmental factors, including temperature fluctuations and chemical exposure. The design of drag chains is characterized by a series of interconnected links that can open for easy installation and maintenance.

The links of a drag chain can be assembled in a variety of ways to accommodate different types of cables and hoses. Some chains feature a single piece design, while others may have multiple compartments. This modularity not only allows for easy customization but also enables the drag chain to expand or contract based on the application's requirements.

Advantages of Using Plastic Drag Chains

One of the most significant advantages of plastic drag chains is their ability to protect cables from abrasion and external damage, which can be caused by movement or environmental factors. This protective feature significantly increases the lifespan of cables and hoses, ultimately reducing maintenance costs and downtime.

In addition, plastic drag chains enhance the organization of cables and hoses within machines, preventing tangles and ensuring that everything operates smoothly. Their design promotes an efficient layout, allowing technicians to easily access specific cables when maintenance is necessary.

plastic drag chain

Another notable benefit of plastic drag chains is their weight. Compared to metal alternatives, plastic drag chains are considerably lighter, making them easier to handle and install. This lightweight feature also contributes to the overall reduction of machine weight, which can be a crucial factor in mobile applications or robotic systems.

Applications of Plastic Drag Chains

Plastic drag chains can be widely found across various sectors, including manufacturing, robotics, CNC machining, and automation. In manufacturing environments, they are used to manage the cables connecting machines and equipment, ensuring that power and data lines remain organized and protected.

In robotics, drag chains are indispensable for allowing flexible movement without the hindrance of tangled wires. They ensure that cables are securely housed while still permitting the full range of motion necessary for robotic systems.

Similarly, in CNC machining, drag chains protect the multitude of cables that connect the machine's components, thereby ensuring a smooth operational flow. Their adaptability and protective qualities make them a staple in automated systems where precision is paramount.

Conclusion

In conclusion, plastic drag chains are a vital component in modern machinery, providing essential protection and organization for cables and hoses. Their durability, lightweight design, and versatility make them an ideal choice for numerous industrial applications. As technology continues to evolve, the role of plastic drag chains will undoubtedly expand, further enhancing operational efficiency and safety across various sectors. For any business seeking to improve the longevity and performance of its equipment, investing in high-quality plastic drag chains is a wise decision.