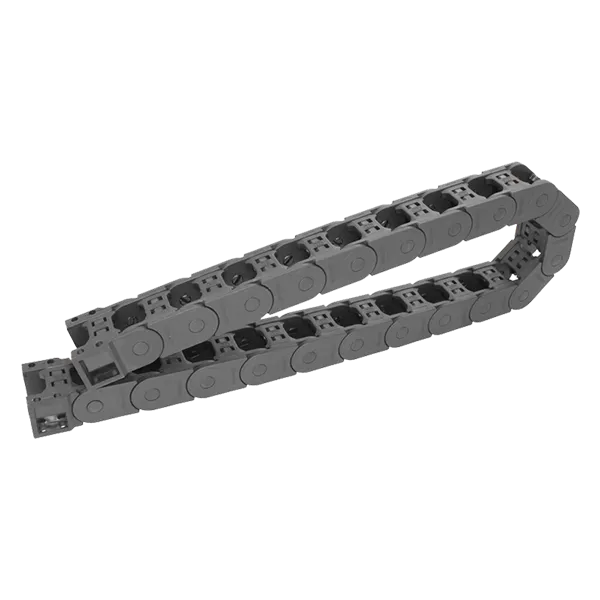

plastic corrugated conduit

The Versatility of Plastic Corrugated Conduit

Plastic corrugated conduit is a remarkable material that has gained significant popularity in various industries due to its unique properties and versatile applications. This lightweight, flexible tubing is primarily made from high-density polyethylene (HDPE) or polyvinyl chloride (PVC), which makes it resistant to a wide range of environmental factors. Its special design—characterized by a series of alternating ridges and grooves—provides added strength and flexibility, making it ideal for various uses, particularly in electrical protection.

One of the primary advantages of plastic corrugated conduit is its resistance to moisture and chemical exposure. This feature makes it suitable for outdoor applications, where it can endure harsh weather conditions, including rain, snow, and extreme temperatures. It is also resistant to many chemicals, making it a favored choice in industries such as construction, telecommunications, and automotive. By safeguarding electrical wiring from the elements, corrugated conduit plays a crucial role in ensuring the longevity and reliability of electrical systems.

Additionally, the flexibility of plastic corrugated conduit allows it to be easily installed in tight spaces and around corners, accommodating the design requirements of complex infrastructures. This aspect saves both time and labor costs during installation. Unlike rigid conduits, which can be cumbersome and difficult to maneuver, corrugated conduits can be bent and twisted without compromising their structural integrity, providing a practical solution for modern wiring needs.

plastic corrugated conduit

Another noteworthy benefit of plastic corrugated conduit is its lightweight nature. This characteristic not only facilitates transportation and installation but also reduces overall construction weight, which can be vital in projects with weight-sensitive specifications. Lightweight conduits also provide ease of handling, making them a more efficient choice for contractors and workers on-site.

Moreover, plastic corrugated conduit is environmentally friendly. Many manufacturers are now adopting recycled materials in their production processes, contributing to sustainability initiatives. Additionally, their durability means they can last for many years without needing replacement, further reducing environmental impact. The recyclability of these materials at the end of their life cycle emphasizes the growing trend towards sustainable construction practices.

In terms of fire safety, it's worth noting that many plastic corrugated conduits are manufactured with additives that enhance their flame-retardant properties, ensuring safer installations in residential and commercial buildings. Compliance with national and international safety standards is critical in the electrical industry, and many corrugated conduit products meet these rigorous standards, providing peace of mind to builders and property owners.

In conclusion, plastic corrugated conduit emerges as an essential component in the realm of electrical and construction applications. Its combination of flexibility, strength, chemical resistance, and environmental sustainability makes it a preferred choice for modern infrastructure projects. As industries continue to innovate and evolve, the demand for reliable materials like plastic corrugated conduit will only increase, reinforcing its important role in the future of electrical installations. Whether for residential, commercial, or industrial use, this versatile conduit stands as a testament to the advancements in material technology and sustainable practices within the industry.