Durable Plastic Cable Chains for Efficient Cable Management Solutions in Various Industries

The Versatility and Importance of Plastic Cable Chain Tracks in Modern Applications

In today’s fast-paced industrial landscape, the demand for efficient and organized cable management systems has never been higher. Among the numerous solutions available, plastic cable chain tracks have emerged as a vital component in various sectors, ranging from manufacturing to robotics. These flexible, lightweight, and durable systems play a crucial role in ensuring that cables are managed effectively, thereby enhancing the safety and efficiency of operations.

What are Plastic Cable Chain Tracks?

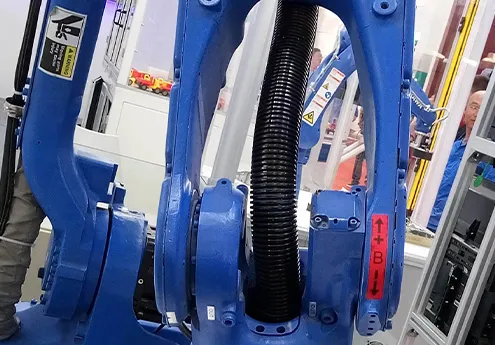

Plastic cable chain tracks, also known as drag chains or cable carriers, are designed to support and guide moving cables and hoses. These chains are composed of interconnected links, which can be easily modified according to specific applications. Made from high-quality, durable plastic materials, they exhibit excellent resistance to wear and tear, making them suitable for a wide range of environments, including those that are harsh and abrasive.

Key Features and Benefits

One of the most significant advantages of plastic cable chain tracks is their flexibility. They can be customized to accommodate a variety of cable sizes and configurations, ensuring that different types of cables can be neatly organized and routed without the risk of damage. This customization capability is especially beneficial in automated machinery where space is limited, and every inch counts.

Additionally, plastic chain tracks are lightweight, which is particularly advantageous in applications where weight reduction is critical. Robots, for example, benefit from the low mass of these tracks, allowing for quicker, more agile movements without compromising structural integrity. Furthermore, the smooth design of plastic tracks reduces friction, which minimizes wear on cables and prolongs their lifespan.

Another notable benefit is the ease of installation and maintenance. Plastic cable chain tracks are designed for user-friendly setup, often featuring plug-and-play connectivity. This simplifies the installation process, reducing downtime during setups or repairs. Moreover, as these chains contain no metal components, they are resistant to corrosion, ensuring reliability in even the most challenging environments.

plastic cable chain track

Applications Across Industries

Plastic cable chain tracks have found application in various industries. In manufacturing plants, they ensure that power cables and data lines are safely guided, preventing tangling and damage as machinery operates. In robotics and automation, these tracks support movement while keeping cables neatly organized, allowing for the seamless operation of robotic arms and other automated mechanisms.

Moreover, the automotive industry also utilizes plastic cable tracks to guide and protect wires and hoses that control essential vehicle functions. In the entertainment industry, they are used in stage lighting and sound equipment, where precision and reliability are paramount.

Environmental Considerations

With growing concerns about environmental sustainability, the materials used to manufacture plastic cable chain tracks are increasingly becoming a focus. Many companies are now producing these chains from recycled plastics or developing biodegradable options that reduce their environmental impact. This shift not only addresses the demand for sustainable solutions but also aligns with the global push towards greener practices within industries.

Conclusion

As industries continue to evolve towards more sophisticated automated processes, the importance of efficient cable management solutions like plastic cable chain tracks cannot be overstated. Their versatility, lightweight nature, and overall durability make them an indispensable asset in various applications. As manufacturers increasingly recognize the benefits these systems provide, the future of cable management looks promising, paving the way for advancements that could lead to even greater efficiencies in production, safety, and sustainability. In a world where technology and innovation drive progress, plastic cable chain tracks stand out as a testament to human ingenuity in managing complexity with simplicity.