Plastic Cable Chain Solutions for Efficient Cable Management and Organization

Exploring the Versatility of Plastic Cable Chains

In today’s industrial landscape, the demand for efficient cable management solutions is ever-increasing. Among the many options available, plastic cable chains stand out for their versatility, durability, and practicality. These cable management systems are engineered to protect and guide cables, hoses, and wires, ensuring that they function smoothly and efficiently in a variety of applications.

What Are Plastic Cable Chains?

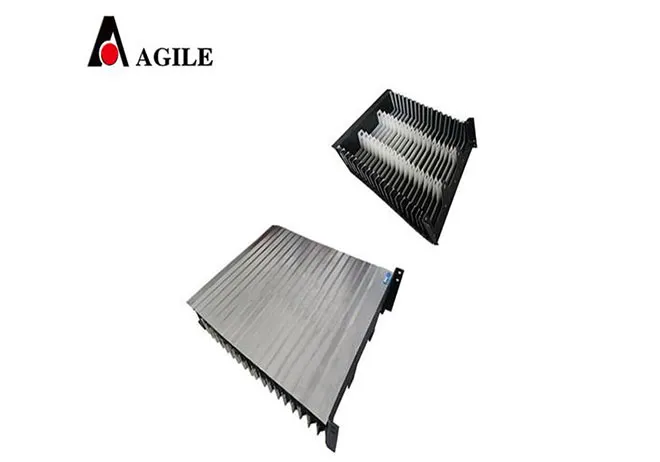

Plastic cable chains, also known as energy chains or drag chains, are flexible enclosures made from high-strength plastic materials. They are designed to carry moving cables or hoses in machinery, robotics, and other automated systems. The design typically consists of a series of interconnected links, which allows the chain to bend and flex while maintaining the protective enclosure around the cables it houses.

Advantages of Plastic Cable Chains

1. Lightweight and Flexible One of the primary benefits of plastic cable chains is their lightweight nature. Unlike metal chains, plastic chains reduce the overall weight of the assembly, which is particularly crucial in mobile applications. This lightness, combined with flexibility, allows them to navigate bends and corners easily, making them ideal for machinery that requires dynamic movement.

2. Corrosion Resistance Plastic is inherently resistant to rust and corrosion, which makes plastic cable chains suitable for outdoor or humid environments. This quality extends their lifespan and reduces maintenance costs, as businesses do not need to worry about the effects of moisture or corrosive substances affecting their operations.

3. Reduced Noise Levels In industrial settings, noise can be a significant issue. The smooth operation of plastic cable chains minimizes vibrations and noise, making them preferable in environments where sound levels should be kept to a minimum. This characteristic can also contribute to a more comfortable working environment for employees.

4. Customization Plastic cable chains can be easily customized to meet specific application needs. Manufacturers offer a wide range of sizes, shapes, and colors, allowing businesses to choose a solution that fits their specific machine layout and aesthetic preferences. Furthermore, these chains can be designed to accommodate different types and sizes of cables or hoses, showcasing their adaptability in diverse applications.

plastic cable chain

5. Cost-Effective Solution While the initial investment in plastic cable chains might be significant, the long-term savings they offer make them a cost-effective choice. Their durability reduces frequent replacements, and their lightweight nature can lead to lower energy costs in machinery operations. Overall, the return on investment justifies the purchase price.

Applications of Plastic Cable Chains

Plastic cable chains are utilized in various industries, including

- Manufacturing and Automation Used extensively in CNC machines, assembly lines, and robotic arms, plastic cable chains ensure that cables remain organized and protected. - Automotive Industry In automotive manufacturing, these chains are employed for managing sensor cables, pneumatic hoses, and electrical lines in assembly processes.

- 3D Printing With the rise of 3D printing technology, plastic cable chains play a crucial role in controlling the movement of print heads and other components, ensuring precision in manufacturing.

- Medical Equipment In healthcare, cable chains help manage wires in diagnostic machines and other medical devices, allowing for safe and efficient operation.

Conclusion

As industries continue to innovate and automate, the importance of effective cable management grows. Plastic cable chains offer a reliable solution that addresses the unique challenges of dynamic systems while promoting efficiency and safety. With their many advantages and wide range of applications, plastic cable chains are set to become a staple in future designs and installations, proving that thoughtful engineering can lead to enhanced operational excellence. In a world where technology is ever-evolving, solutions like plastic cable chains not only support current needs but also pave the way for future advancements in cable management systems.