Durable Solutions for Managing Cables with Plastic Cable Chains in Various Applications

The Rise of Plastic Cable Chains A Revolution in Cable Management

In today's fast-paced technological environment, efficient cable management has become a critical aspect of various industries, from manufacturing and robotics to telecommunications and home entertainment systems. Among the myriad solutions available, plastic cable chains have emerged as a preferred choice for many companies and individuals seeking to streamline their operations. This article explores the benefits, applications, and future potential of plastic cable chains in modern settings.

What Are Plastic Cable Chains?

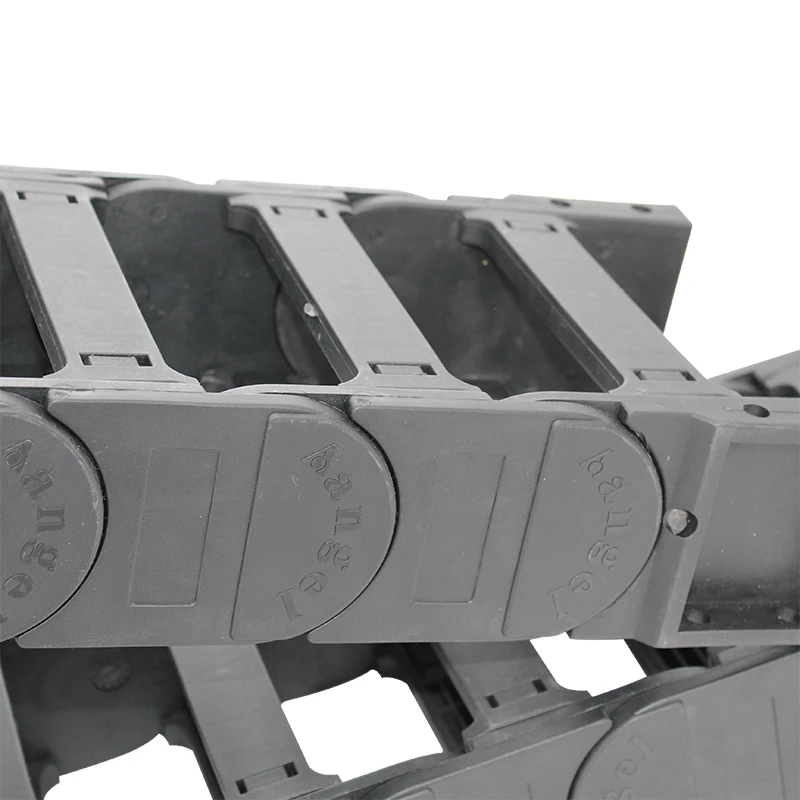

Plastic cable chains, often referred to as energy chains or drag chains, are systems designed to guide and protect cables and hoses in dynamic applications. Made from high-quality plastics, these chains consist of repetitive links that can accommodate various cable types, including power cables, communication cables, and hydraulic hoses. They are designed to move flexibly and can withstand the rigors of continuous motion, which is essential for applications where robotic arms, conveyors, or other machinery are in constant operation.

Benefits of Plastic Cable Chains

1. Durability and Longevity One of the primary benefits of plastic cable chains is their inherent resistance to wear and tear. Made from robust materials such as Nylon and Polypropylene, they can withstand harsh environments and resist chemical exposure, ensuring they last longer than traditional metal cable carriers.

2. Lightweight Design The lightweight nature of plastic chains reduces the overall weight of machinery and equipment, which is particularly crucial in robotic applications where excess weight can affect performance and precision.

3. Flexibility and Customization Plastic cable chains can easily be customized in terms of size, shape, and color, making them suitable for various applications. Their flexibility allows them to bend and twist in multiple orientations without damaging the cables inside, accommodating complex movements in robotics or assembly lines.

4. Ease of Installation and Maintenance Installing plastic cable chains is generally straightforward, as they can be easily mounted on existing machinery. Additionally, they allow for quick cable replacement and maintenance, minimizing downtime and enhancing productivity.

5. Noise Reduction Many plastic cable chains are designed with noise-dampening features, which can help in reducing the overall noise levels in environments where machinery operates, creating a more pleasant work atmosphere.

plastic cable chain

Applications of Plastic Cable Chains

Plastic cable chains find applications across various sectors, including

- Industrial Robotics In the automation sector, robotic arms require efficient cable management to maintain movement without snagging. Plastic cable chains provide a reliable solution for guiding power and data cables, enhancing the robot's operational efficiency.

- Machine Tools In machining operations, plastic chains protect cables from becoming entangled in the moving parts of machinery, thus prolonging cable life and reducing maintenance costs.

- Automotive and Aerospace In the automotive and aerospace industries, rigorous standards for reliability and safety exist. Plastic cable chains meet these standards while providing a lightweight, durable means of managing complex electrical systems.

- Conveyor Systems Conveyor systems often deal with a multitude of cables that require organization and protection. Plastic cable chains allow for smooth movement of cables, reducing wear and tear and potential hazards.

- Home and Commercial Electronics Beyond industrial applications, plastic cable chains are becoming popular in homes and offices, where they can help manage computer cables, electronic device connections, and audiovisual equipment.

The Future of Plastic Cable Chains

As technology continues to advance, the demand for more sophisticated and functional cable management systems will only increase. The future of plastic cable chains looks promising, with ongoing innovations focused on enhancing their materials and applications. This could lead to even more durable and versatile solutions that cater to the specific needs of high-tech industries. Furthermore, the trend towards sustainability may promote the use of recycled or biodegradable plastics in the production of cable chains, aligning with global efforts toward environmentally friendly manufacturing practices.

In conclusion, plastic cable chains represent a significant advancement in the field of cable management. Their durability, lightweight design, and versatility make them an essential component in numerous applications. As industries continue to explore new technologies and methods, plastic cable chains will undoubtedly play a critical role in ensuring efficiency and reliability in an ever-evolving landscape.