plastic cable chain

Understanding Plastic Cable Chains Benefits and Applications

In the modern industrial landscape, efficiency and organization are paramount. One crucial component in achieving this is the use of plastic cable chains, also known as energy chains or drag chains. These devices play a vital role in protecting and guiding flexible cables and hoses in various applications, from manufacturing to robotics. In this article, we will delve into the advantages, types, and applications of plastic cable chains.

What are Plastic Cable Chains?

Plastic cable chains are designed to facilitate the movement of cables and hoses across a predetermined path. They consist of interlocking plastic links that allow for smooth and controlled motion. These chains are typically mounted along a linear path where equipment moves in a repeated cycle, such as in automated machinery, CNC machines, and assembly lines. By enclosing the cables and hoses within the links, users can prevent tangling, abrasion, and wear, thus prolonging the lifespan of the cables and ensuring consistent reliability.

Advantages of Plastic Cable Chains

1. Flexibility and Versatility One of the most significant benefits of plastic cable chains is their adaptability. They can be used in a wide variety of applications, including vertical and horizontal movements. Whether used in robotics, conveyor systems, or CNC machines, plastic cable chains can accommodate different shapes and sizes of cables and hoses.

2. Durability Made from high-quality plastics such as nylon and polypropylene, these chains are resistant to wear, chemicals, and extreme temperatures. Their robust construction allows them to withstand harsh operating environments, making them a favorite in industries like automotive, aerospace, and pharmaceuticals.

3. Reduced Maintenance By organizing and protecting cables, plastic cable chains significantly reduce the need for regular maintenance. The protective housing prevents dust and debris from accumulating on the cables, decreasing the chances of malfunction and breakdowns. This aspect not only saves time but also reduces operational costs.

4. Noise Reduction In many industrial settings, noise can be a significant concern. Plastic cable chains can be designed to minimize vibration and noise, creating a quieter work environment and contributing to better employee comfort and productivity.

plastic cable chain

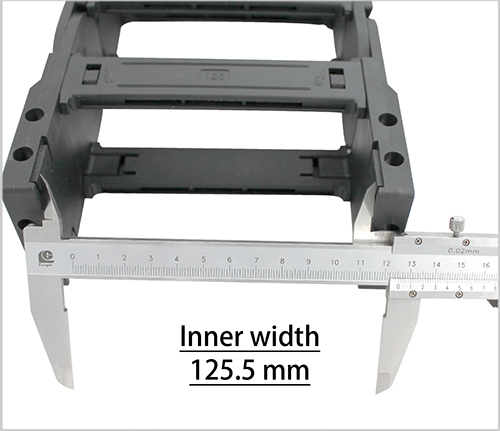

5. Easy Installation and Customization Plastic cable chains are easy to install and can be customized to fit specific requirements. They come in various sizes, lengths, and configurations, allowing engineers to design an efficient cable management system tailored to their operations.

Applications of Plastic Cable Chains

1. Manufacturing and Automation In automated production lines, plastic cable chains guide power and data cables to various processing equipment, ensuring seamless operation and reducing the risk of tangling.

2. Robotics In robotic arms and automated machines, these chains manage the movement of cables while allowing for full range-of-motion functionality. This is crucial in scenarios where precision and speed are required.

3. Machine Tools Plastic cable chains are widely used in CNC machines to protect and manage the cables that power the machine's movements, ensuring that operations run smoothly without interruptions caused by cable damage.

4. Material Handling Within conveyor systems, cable chains help manage the multitude of cables, from power lines to sensor connections, essential for the smooth operation of the entire system.

5. Aerospace and Automotive The lightweight and durable nature of plastic cable chains makes them ideal for the aerospace and automotive industries, where weight savings and reliability are critical factors.

In conclusion, plastic cable chains offer numerous advantages that make them indispensable in various industrial applications. Their ability to protect, organize, and streamline cable management can lead to significant efficiency gains and reduced operational costs. As industries continue to evolve, the role of plastic cable chains will undoubtedly remain prominent, ensuring that machinery and equipment operate effectively and reliably.