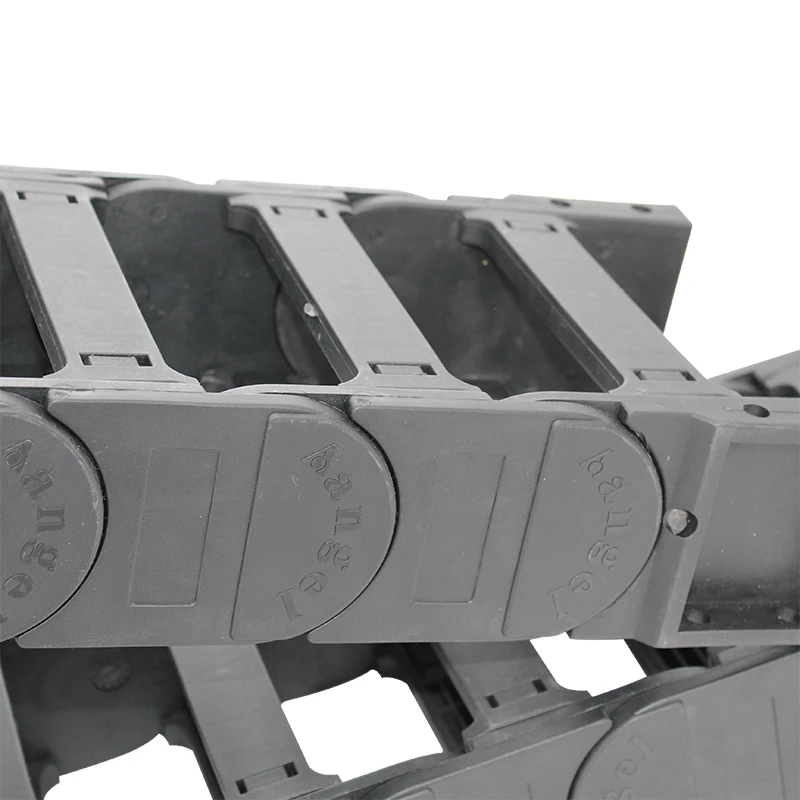

Durable Plastic Cable Carrier Solutions for Efficient Cable Management and Protection

Understanding Plastic Cable Carriers A Key Component in Cable Management

In today’s industrial landscape, effective cable management is essential for ensuring safety, efficiency, and reliability in various systems, from manufacturing plants to automation setups. One of the critical components in achieving optimal cable organization is the plastic cable carrier, also known as drag chain or energy chain. This article explores the purpose, benefits, and applications of plastic cable carriers, showcasing their significance in modern engineering.

What is a Plastic Cable Carrier?

A plastic cable carrier is a specialized conduit designed to hold and protect flexible cables and hoses as they move within machinery or systems. Unlike traditional cable management solutions, which may rely on simple bundling or securing methods, plastic cable carriers are engineered to provide dynamic support, allowing for movement without causing wear and tear on the cables. They are composed of lightweight yet durable materials, typically made from high-performance plastics, which enhance their longevity and resilience against environmental factors.

Key Benefits of Plastic Cable Carriers

1. Protection of Cables and Hoses One of the primary functions of a plastic cable carrier is to safeguard cables from abrasion, crushing, and excessive bending. By enclosing cables in a protective chain shape, these carriers allow them to move freely while mitigating potential damage during operation.

2. Reduced Downtime Downtime caused by cable failure or damage can be costly for businesses. The protective qualities of plastic cable carriers significantly reduce the risk of cable-related issues, ensuring that machinery runs smoothly and maintenance interruptions are minimized.

3. Enhanced Flexibility Plastic cable carriers are designed to accommodate various cable types and sizes. Their flexibility allows them to be used in multiple applications, adapting to different movement patterns—whether linear, rotational, or multi-axial—making them suitable for complex machinery setups.

4. Weight Savings Compared to metal alternatives, plastic cable carriers are significantly lighter, which results in less added weight to the moving parts of machinery. This weight reduction can lead to increased efficiency and lower energy consumption, which is crucial in applications like robotics and CNC machines.

5. Corrosion Resistance Many plastics used in cable carriers are inherently resistant to chemicals and corrosion, making them ideal for harsh environments. This resistance extends the life span of both the carrier and the cables within, ensuring dependable performance.

plastic cable carrier

Applications of Plastic Cable Carriers

The versatility of plastic cable carriers allows them to be utilized across various industries and applications. Here are a few notable examples

1. Manufacturing and Assembly Lines In production environments where equipment moves along a fixed path, plastic cable carriers are essential for managing power and control cables, preventing tangling and wear.

2. Robotics Robots often require a complex array of sensors and power cables. Plastic cable carriers facilitate smooth motion while allowing for flexibility as the robotic arms move, ensuring consistent performance without cable strain.

3. CNC Machining In CNC machines, where precision is paramount, these carriers protect critical signals and power lines that drive the machinery, maintaining the integrity and effectiveness of operations.

4. Automotive Industry As vehicles become increasingly sophisticated, plastic cable carriers can be found managing the multitude of electrical and data cables in automotive assembly lines, ensuring efficiency and safety throughout the process.

5. Wind and Hydro Power In renewable energy applications, plastic cable carriers help manage cables in harsh outdoor environments, tolerating extreme weather conditions while ensuring the reliable transmission of power.

Conclusion

Plastic cable carriers are indispensable components in the realm of cable management, providing protection, flexibility, and efficiency across a myriad of applications. As industries continue to evolve and adapt to new technologies, understanding and utilizing these carriers will remain crucial for enhancing the performance and reliability of machinery. Whether in manufacturing, robotics, or renewable energy, plastic cable carriers are a foundational element that contributes significantly to operational success. By investing in high-quality cable carriers, businesses can not only protect their assets but also bolster productivity and safety in an increasingly competitive landscape.