Durable Plastic Cable Carrier Solutions for Efficient Cable Management and Protection

Understanding Plastic Cable Carriers Key Benefits and Applications

In the realm of modern industrial automation and machinery, efficient and organized cable management plays a crucial role in ensuring operational efficiency and longevity of equipment. One of the pivotal components designed to address this need is the plastic cable carrier. Often referred to as drag chains, these components provide a safe and reliable solution for managing electrical cables and hoses in dynamic environments. This article delves into the features, benefits, and applications of plastic cable carriers.

What is a Plastic Cable Carrier?

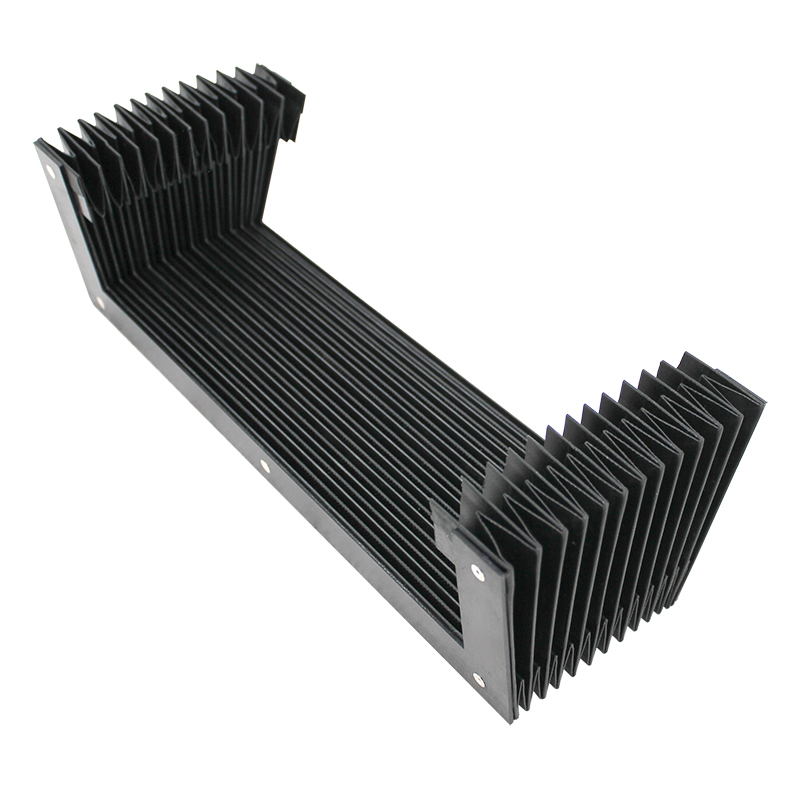

A plastic cable carrier is a flexible, articulated system designed to protect and manage cable assemblies and hoses as they move in machinery and automation setups. Typically constructed from high-strength plastic materials, these carriers allow for smooth movement while minimizing wear and tear on cables and hoses. They are especially advantageous in environments where cables are subject to repetitive motion, such as in CNC machines, robotic arms, and conveyor systems.

Key Benefits of Plastic Cable Carriers

1. Durability and Longevity One of the standout features of plastic cable carriers is their robustness. Made from high-quality plastic polymers, these carriers are resistant to environmental factors such as chemicals, UV rays, and moisture, which can degrade metal alternatives. This resilience ensures longer service life and reduces the frequency of replacements.

2. Lightweight Design Compared to metal carriers, plastic cable carriers are significantly lighter. This lightweight property not only contributes to overall machine efficiency by reducing dead weight but also facilitates easier installation and mobility.

3. Flexibility and Customization Plastic cable carriers can be easily customized to suit specific application requirements. They come in various sizes, shapes, and configurations, allowing for an optimal fit in intricate machinery designs. Additionally, they can be manufactured with specific bend radii to accommodate different movement dynamics.

4. Noise Reduction The design of plastic carriers often includes noise-dampening features. Their plastic composition minimizes friction compared to metal alternatives, leading to quieter operation—a substantial benefit in settings where noise control is essential.

5. Ease of Maintenance Most plastic cable carriers are designed for tool-free assembly and disassembly. This user-friendly characteristic significantly reduces maintenance time when accessing cables for repairs or replacements.

plastic cable carrier

Applications of Plastic Cable Carriers

Plastic cable carriers are utilized across a broad spectrum of industries and applications

- Robotics In robotics, these carriers ensure that power cables and data lines remain organized and protected during the rapid movement of robotic arms. They help prevent issues such as cable tangling and wear, which can lead to costly downtimes.

- CNC Machining CNC machines often involve complex movements and require reliable cable management systems. Plastic cable carriers effectively safeguard the cables involved in machinery operation, contributing to precision engineering workflows.

- Material Handling In conveyor systems, these carriers facilitate organized cable routing, essential for the smooth operation of materials and products without interruption.

- Automotive Industry In automotive manufacturing, where automated systems are prevalent, plastic cable carriers guide electrical and hydraulic lines through various machine movements, enhancing assembly line efficiency.

- Textile and Printing Manufacturing processes in the textile and printing industries often require precise movements and cable management, making plastic cable carriers an ideal solution to enhance production reliability.

Conclusion

Plastic cable carriers are an indispensable aspect of modern machinery and automation. Their durability, lightweight design, flexibility, and ease of maintenance make them superior choices for managing cables and hoses in various dynamic environments. As technology continues to evolve, the applications and innovations surrounding plastic cable carriers are expected to expand, further solidifying their role in driving efficiency and productivity in industrial settings. Whether in robotics, CNC machining, or automotive manufacturing, these components provide the reliability and functionality needed for today's high-tech environments.