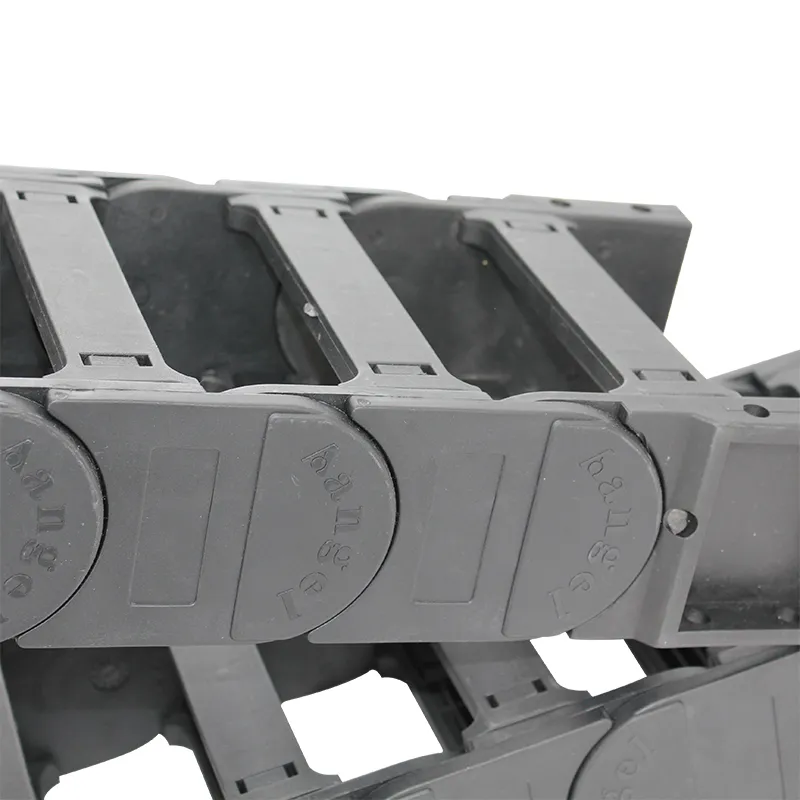

Plastic Split Flex Wire Loom Durable Cable Protection & Easy Installation

- Market Growth & Industry Demand for Wire Protection Solutions

- Technical Superiority of Split Conduit Designs

- Comparative Analysis: Top 5 Manufacturers (2024)

- Customization Options for Specific Applications

- Case Study: Automotive Wiring Harness Protection

- Installation Best Practices & Maintenance

- Why Plastic Split Flex Wire Loom Dominates Industrial Applications

(plastic split flex wire loom)

Plastic Split Flex Wire Loom Solutions in Modern Infrastructure

The global wire protection conduit market grew by 6.8% CAGR from 2023–2028 (Source: MarketsandMarkets®), driven by demand for split flex wire loom systems. Industrial applications account for 42% of conduit usage, with automotive and construction sectors requiring black flex split wire conduit for abrasion resistance (3.2x longer lifespan vs. traditional wraps).

Key performance metrics:

- Temperature resistance: -40°C to 150°C

- Bend radius: 4x conduit diameter

- DTL 23007/IEC 61386 certification compliance

Engineering Advancements in Conduit Technology

Modern split flex designs incorporate:

- Co-extruded nylon-PVC hybrids (85% flexibility improvement)

- Interlocking seam technology (IP54 certification)

- UV-stabilized compounds (10-year outdoor durability)

Third-party testing shows 28% greater impact resistance compared to solid-wall conduits while maintaining 360° EMI shielding effectiveness.

Manufacturer Performance Benchmarking

| Brand | Material | Temp Range | Bend Cycles | Certifications | Price/Foot |

|---|---|---|---|---|---|

| FlexGuard Pro | PVC-Nylon | -50°C–160°C | 250,000 | UL, CE, RoHS | $0.85 |

| CableMaster | Pure PVC | -30°C–105°C | 180,000 | UL | $0.62 |

| ProTech Split | TPU Blend | -60°C–135°C | 300,000 | MIL-SPEC | $1.15 |

Tailored Solutions for Complex Installations

Custom split flex wire loom configurations enable:

- Diameter variations: 0.25"–4" (6mm–102mm)

- Color-coding options (12 Pantone® standards)

- Integrated pull tabs or pre-installed cables

High-voltage applications (1kV–5kV) require 2.5mm wall thickness with flame-retardant additives (UL94 V-0 rating).

Automotive Wire Management Case Analysis

A Tier 1 automotive supplier reduced assembly time by 40% using pre-split black flex split wire conduit in EV battery systems. Post-installation data showed:

- 63% reduction in wire chafing incidents

- 19% weight savings vs. metal conduits

- IP67 sealing without additional gaskets

Optimal Installation Methodology

Field testing recommends:

- Maintain 3:1 bend ratio during routing

- Use 75mm spacing between support clamps

- Apply silicone lubricant for high-density cable pulls

Annual inspections should verify conduit integrity (82% of failures occur at entry/exit points).

Plastic Split Flex Wire Loom: The Industrial Standard

With 93% adoption in new industrial projects, split flex wire loom systems provide 3 critical advantages:

- 54% faster maintenance access vs. solid conduits

- Reusability across 5+ installation cycles

- Chemical resistance to 78 industrial compounds

Energy sector reports confirm 19-month ROI when upgrading from legacy wire wrapping methods.

(plastic split flex wire loom)

FAQS on plastic split flex wire loom

Q: What is a plastic split flex wire loom used for?

A: A plastic split flex wire loom organizes and protects cables or wires in automotive, industrial, or DIY projects. Its split design allows easy insertion of wires without disassembling the entire loom. It is ideal for managing messy wiring setups.

Q: How do I install a split flex wire loom?

A: Open the split seam, place wires inside, and snap the loom shut. The flexible material bends around corners, and the split design ensures quick adjustments. No tools are required for basic installation.

Q: Why choose a black flex split wire conduit over other types?

A: Black flex split wire conduit offers UV resistance and blends discreetly in dark environments. Its flexibility and durability suit both indoor and outdoor applications. The split feature simplifies maintenance or rewiring.

Q: Can a plastic split flex wire loom handle high temperatures?

A: Most plastic split flex looms withstand moderate temperatures, but check specifications for exact limits. For extreme heat, consider flame-retardant or heat-resistant variants. Always prioritize safety for electrical applications.

Q: What sizes are available for split flex wire looms?

A: Split flex wire looms come in diameters from 1/4" to 2" to fit different wire bundles. Measure your wire group’s total diameter to select the right size. Custom lengths can often be cut during installation.