Optimizing Efficiency with Chip Conveyor Systems in CNC Machining Operations and Processes

The Importance of Chip Conveyors in CNC Machining

In the realm of CNC (Computer Numerical Control) machining, efficiency and precision are paramount. One often overlooked yet crucial component of this process is the chip conveyor. Chip conveyors play an integral role in maintaining the effectiveness of CNC machines by managing the byproducts of the machining process—metal chips and debris. This article explores the significance, types, and benefits of chip conveyors in CNC machining.

What Is a Chip Conveyor?

A chip conveyor is a specialized mechanism designed to transport metal chips away from the workspace of CNC machines. During machining operations, tools cut into metal workpieces, producing waste material in the form of chips. If these chips accumulate, they can negatively affect the machine's performance, leading to potential downtime, safety hazards, and reduced machining accuracy. Chip conveyors help minimize these issues by continuously removing debris, ensuring a clean and efficient working environment.

Types of Chip Conveyors

There are various types of chip conveyors, each suited to different machining needs and types of materials. The most common types include

1. Drag Chain Conveyors Utilizing a chain that drags metal chips along a designated path, drag chain conveyors provide a robust solution for transporting large and heavy chips commonly generated in machining operations.

2. Auger Conveyors These conveyors employ a rotating screw-like mechanism to move chips efficiently. They are particularly effective for finer chips and can navigate through curved paths, making them versatile in layout design.

3. Magnetic Chip Conveyors Ideal for transporting ferromagnetic materials, magnetic chip conveyors utilize magnets to move metal chips along a surface. Their design minimizes wear and stress on components, extending the lifespan of the conveyor.

4. Belt Conveyors These use a belt to carry chips away from the machining area. They are widely used due to their simplicity and effectiveness in handling various chip sizes and types.

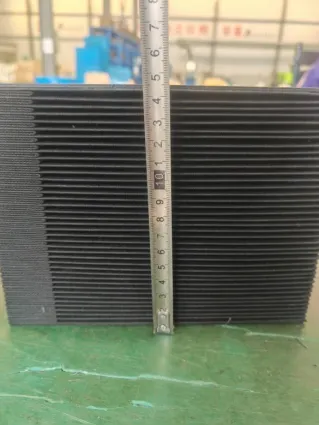

chip conveyor cnc machine

Benefits of Chip Conveyors

The benefits of incorporating chip conveyors into CNC machining processes are multifaceted

1. Increased Efficiency By continuously removing chips from the work area, chip conveyors maintain optimal machine performance. This reduces the likelihood of interruptions that can occur when machines become clogged with debris.

2. Enhanced Safety Accumulated metal chips can create hazards by obstructing pathways and creating slip risks. Chip conveyors help to eliminate these risks, ensuring a safer working environment for operators.

3. Improved Machining Accuracy A clean workspace is crucial for maintaining precision in CNC machining. The removal of chips minimizes the chances of errors caused by debris interfering with the machining process.

4. Reduced Maintenance Costs By preventing chip build-up, chip conveyors can prolong the lifespan of CNC machines. Regular maintenance and repair costs can be significantly lowered when machines operate under optimal conditions.

5. Environmental Benefits Efficient chip removal not only improves the machining environment but also facilitates easier recycling of byproducts. Many chip conveyors can be integrated with systems that separate and recycle metal chips, contributing positively to sustainability efforts.

Conclusion

In conclusion, chip conveyors are a vital element in the CNC machining ecosystem. Their ability to efficiently manage metal chips enhances productivity, safety, and machining accuracy while reducing maintenance costs. As CNC technology continues to evolve, the importance of effective chip management will only increase, making chip conveyors an indispensable part of modern machining processes. Investing in the right chip conveyor system can lead to significant improvements in overall operational efficiency, paving the way for a more productive manufacturing environment.