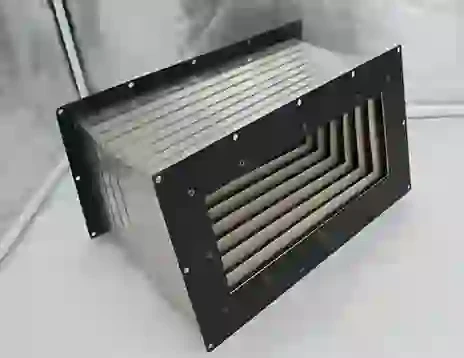

open drag chain

Understanding Open Drag Chains A Comprehensive Overview

In the world of machinery and equipment, efficiency and organization are paramount. One often overlooked yet essential component that enhances both is the drag chain, particularly the open drag chain. This article seeks to shed light on open drag chains, their components, benefits, applications, and maintenance, ensuring you have a thorough understanding of this important tool.

What is an Open Drag Chain?

Open drag chains, sometimes referred to as cable carriers or energy chains, are devices designed to protect and guide cables and hoses in various machinery and automated systems. Unlike traditional enclosed drag chains, open drag chains consist of a modular design that features links or segments that are exposed on the sides. This configuration allows for easy access to cables and hoses for maintenance or replacement without disassembling the entire chain.

Components of Open Drag Chains

An open drag chain typically consists of several essential components

1. Links These are the building blocks of the drag chain. Each link is designed to interlock with adjacent links, allowing flexibility and adaptability. Open drag chain links are usually made of durable materials like nylon or polypropylene, ensuring longevity and reliability.

2. Separator Plates These plates are inserted within the chain to compartmentalize different cables or hoses, preventing them from tangling and ensuring organized movement. This feature is crucial in industrial applications where multiple cables need to coexist without interference.

3. End Connectors Used to secure the drag chain to machinery, these connectors ensure stability during operation. They are often customizable to fit various setups, making the open drag chain a versatile option.

Benefits of Open Drag Chains

Open drag chains offer numerous advantages over their enclosed counterparts

1. Ease of Maintenance The open design allows users to easily access and replace cables or hoses without having to dismantle the entire assembly. This saves time and labor costs, contributing to overall operational efficiency.

2. Improved Cable Management By keeping cables organized and segregated, open drag chains prevent tangling, wear, and tear. This organization extends the lifespan of cables and reduces the risk of downtime due to cable failures.

3. Adaptability Open drag chains can be customized to fit various applications, from robotics to conveyor systems. Their modular nature allows for easy resizing and configuration changes as machinery evolves.

4. Temperature and Environment Resistance Many materials used in open drag chains are resistant to oil, chemicals, and extreme temperatures, making them suitable for demanding industrial environments.

open drag chain

Applications of Open Drag Chains

Open drag chains have a wide range of applications across multiple industries

- Manufacturing In automated production lines, open drag chains are commonly used to manage power supply and control cables for machinery, ensuring smooth and safe operation.

- Robotics In robotic systems, these chains allow for the free movement of cables while protecting them from wear, making them ideal for applications with dynamic movement.

- CNC Machines Open drag chains are employed in CNC machinery to protect delicate cables, providing flexibility while ensuring precision operations.

- Automated Guided Vehicles (AGVs) These vehicles require efficient cable management systems to navigate complex pathways without interruptions. Open drag chains are perfectly suited for this need.

Maintenance of Open Drag Chains

To ensure the longevity and effectiveness of open drag chains, regular maintenance is essential. Here are a few best practices

1. Regular Inspections Periodically check the integrity of the chain, looking for wear and tear on links or separator plates.

2. Proper Cable Routing Ensure that cables are properly routed within the chain to avoid excessive strain or damage.

3. Lubrication Where appropriate, apply lubrication to reduce friction and wear on the moving parts of the drag chain.

4. Replacement of Worn Parts Quick replacement of any damaged links or components helps maintain the overall functionality of the drag chain.

Conclusion

Open drag chains play a crucial role in enhancing the functionality and efficiency of machinery across various industries. Their modular design, ease of maintenance, and adaptability make them an invaluable component in modern equipment. By understanding the benefits and applications of open drag chains, businesses can better leverage their potential to improve productivity while minimizing downtime and maintenance costs.