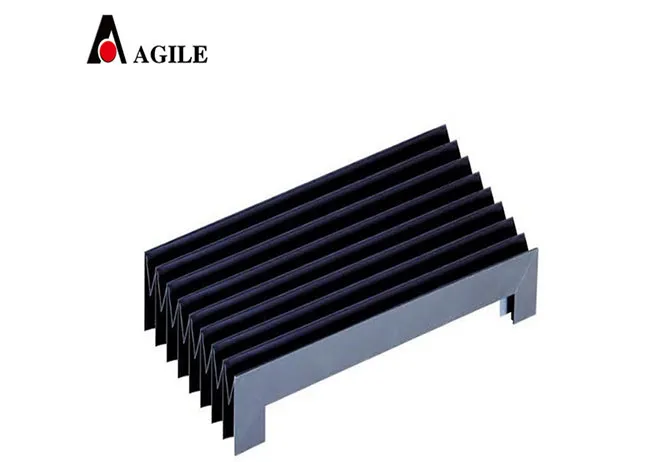

open drag chain

Understanding Open Drag Chains A Guide to Efficient Cable Management

In the world of industrial design and machinery, efficiency and organization are crucial. One critical component that has garnered attention in optimizing these factors is the open drag chain, also known as a cable carrier or drag chain. This article will delve into what open drag chains are, their advantages, applications, and why they are essential for modern engineering setups.

What Are Open Drag Chains?

Open drag chains are a type of cable management system designed to protect and guide flexible cables, hoses, and tubing in dynamic applications. They consist of linked sections that create a channel for cables to move freely without tangling or wear. Unlike enclosed drag chains, open designs provide easy access to the cables inside, allowing for quick maintenance and replacement.

Advantages of Open Drag Chains

1. Accessibility One of the most significant advantages of open drag chains is the ease of access they provide. When the cables need to be inspected or replaced, users can quickly open the chain without disassembling the entire system. This feature significantly reduces downtime and increases productivity.

2. Flexibility Open drag chains are highly versatile. They can accommodate a wide range of cable types, including power cables, data cables, and pneumatic hoses. Depending on the specific requirements of a project, drag chains can be adjusted or modified to fit various needs.

3. Enhanced Durability Constructed from sturdy materials like plastic and metal, open drag chains are built to withstand harsh industrial environments. They resist abrasion, high temperatures, and chemical exposure, ensuring that the associated cables remain protected over time.

4. Improved Aesthetics Beyond functionality, open drag chains also contribute to a more organized workspace. By keeping cables neatly arranged, they help maintain a clean appearance, which is crucial for industries that value professionalism and safety.

open drag chain

5. Reduction of Wear and Tear Open drag chains minimize the risk of cable damage caused by excessive bending or twisting. By guiding the cables along a fixed path, they help maintain the integrity of both the cables and the equipment they connect to.

Applications of Open Drag Chains

Open drag chains are widely used across various industries, including

- Manufacturing In manufacturing plants, automated machinery often requires complex sets of cables and hoses that move continuously. Open drag chains facilitate this movement without hindrance.

- Robotics Robotic systems rely on precision and efficiency. Open drag chains support the routing of wires and hoses, ensuring that they do not get tangled during operation.

- CNC Machines Computer Numerical Control (CNC) machines often have multiple axes of movement, necessitating organized cable placement. Open drag chains provide a viable solution for cable management in CNC setups.

- Automotive In automotive manufacturing, open drag chains help manage wires and hoses related to robotic arms that assemble components, ensuring smooth functioning.

Conclusion

In conclusion, open drag chains are an essential tool for efficient cable management in various industrial applications. Their accessibility, flexibility, durability, and organizational benefits make them a superior choice for environments where cables must be protected and managed carefully. As industries continue to evolve and automation becomes more prevalent, the role of open drag chains will only grow, offering a practical solution to the challenges of modern engineering and manufacturing processes. Embracing this technology can lead to improved efficiency, reduced downtime, and a safer working environment.