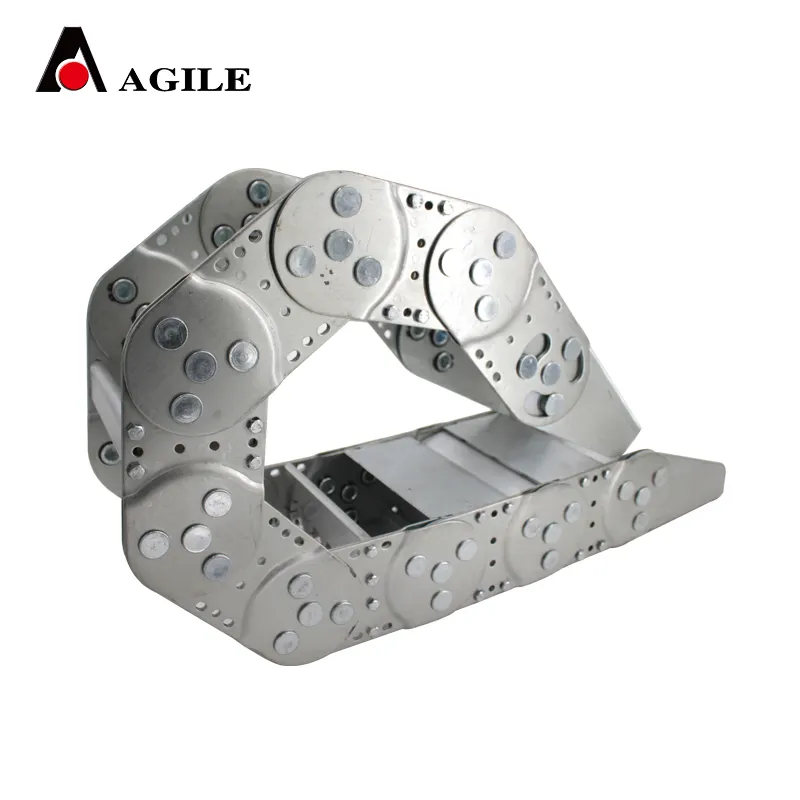

open cable carrier

Navigating the complex world of industrial parts sometimes leads professionals to the innovative technology of open cable carriers. Designed to protect and manage cables and hoses, these components are crucial in ensuring operational efficiency and equipment longevity across a range of industries. As someone deeply embedded in the field, the insights shared herein stem from a blend of extensive industry experience and technical expertise, magnifying the importance of these systems within any mechanical assembly.

It is essential to have an authoritative perspective when advising companies on integrating open cable carriers into new or existing setups. The selection process involves a comprehensive analysis of operational conditions, environment, and the physical demands placed on the system. Professionals leverage their expertise to evaluate these criteria meticulously, delivering recommendations supported by credible data and proven industry standards. Choosing the right system not only optimizes performance but also significantly mitigates risks associated with mechanical failures. Trustworthiness is built on a foundation of reliability and consistent performance, qualities inherent in reputable suppliers of open cable carriers. Companies relying on these systems benefit from reduced maintenance costs and extended equipment lifetime, translating to direct financial savings and enhanced operational capacity. Trusted vendors provide not only high-quality products but also invaluable support services, including installation guidance and maintenance tips, reinforcing the reliability of the entire solution offered. In summary, open cable carriers represent more than just a logistical component in industrial applications; they are a critical element in ensuring the seamless operation and longevity of complex machinery. Professionals equipped with firsthand experience, specialized knowledge, and an authoritative approach provide the backbone for successful implementation and efficient use of these systems, building trust with industry players every step of the way. By prioritizing quality and expertise, businesses can harness the full potential of open cable carriers, securing a competitive edge in their respective fields.

It is essential to have an authoritative perspective when advising companies on integrating open cable carriers into new or existing setups. The selection process involves a comprehensive analysis of operational conditions, environment, and the physical demands placed on the system. Professionals leverage their expertise to evaluate these criteria meticulously, delivering recommendations supported by credible data and proven industry standards. Choosing the right system not only optimizes performance but also significantly mitigates risks associated with mechanical failures. Trustworthiness is built on a foundation of reliability and consistent performance, qualities inherent in reputable suppliers of open cable carriers. Companies relying on these systems benefit from reduced maintenance costs and extended equipment lifetime, translating to direct financial savings and enhanced operational capacity. Trusted vendors provide not only high-quality products but also invaluable support services, including installation guidance and maintenance tips, reinforcing the reliability of the entire solution offered. In summary, open cable carriers represent more than just a logistical component in industrial applications; they are a critical element in ensuring the seamless operation and longevity of complex machinery. Professionals equipped with firsthand experience, specialized knowledge, and an authoritative approach provide the backbone for successful implementation and efficient use of these systems, building trust with industry players every step of the way. By prioritizing quality and expertise, businesses can harness the full potential of open cable carriers, securing a competitive edge in their respective fields.