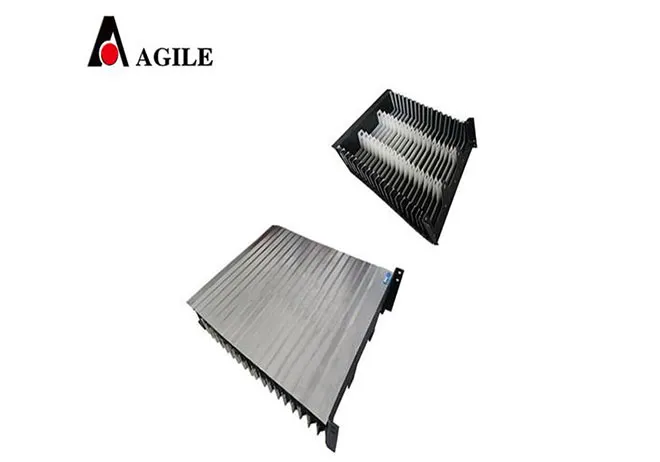

open cable carrier

Open cable carriers have become an indispensable component in modern industrial and manufacturing settings. Their primary function is to support and protect cables and hoses, which are in constant motion, thereby preventing damage and ensuring operational efficiency. For those who have first-hand experience working with industrial machinery, the importance of a reliable open cable carrier cannot be overstated.

Furthermore, industry veterans often share insights on their preferred configurations and customization options for open cable carriers. With manufacturers offering bespoke solutions tailored to various industrial needs, flexibility in design and functionality can be achieved. Practical customization options might include adjustments in width, length, and segmentation, which allow for the efficient accommodation of complex cable arrangements. Real-world experiences shared by technicians also highlight a significant benefit of open cable carriers—the reduction in downtime. Quick visual inspections without dismantling parts of the carrier mean that potential issues can be addressed promptly, minimizing costly interruptions in operations. This aspect speaks volumes about the reliability and trust these systems inspire among users. In summary, the open cable carrier presents a compelling choice for industries that prioritize operational efficiency and equipment longevity. By offering a blend of easy maintenance, material versatility, and customizability, these carriers stand out as an expert-approved solution. Their continued endorsement by authoritative figures in industrial design and maintenance strengthens their position as a trustworthy addition to any cable management arsenal. Whether in a high-tech assembly line or a rugged manufacturing plant, open cable carriers are proving their worth as an essential component for modern machinery.

Furthermore, industry veterans often share insights on their preferred configurations and customization options for open cable carriers. With manufacturers offering bespoke solutions tailored to various industrial needs, flexibility in design and functionality can be achieved. Practical customization options might include adjustments in width, length, and segmentation, which allow for the efficient accommodation of complex cable arrangements. Real-world experiences shared by technicians also highlight a significant benefit of open cable carriers—the reduction in downtime. Quick visual inspections without dismantling parts of the carrier mean that potential issues can be addressed promptly, minimizing costly interruptions in operations. This aspect speaks volumes about the reliability and trust these systems inspire among users. In summary, the open cable carrier presents a compelling choice for industries that prioritize operational efficiency and equipment longevity. By offering a blend of easy maintenance, material versatility, and customizability, these carriers stand out as an expert-approved solution. Their continued endorsement by authoritative figures in industrial design and maintenance strengthens their position as a trustworthy addition to any cable management arsenal. Whether in a high-tech assembly line or a rugged manufacturing plant, open cable carriers are proving their worth as an essential component for modern machinery.