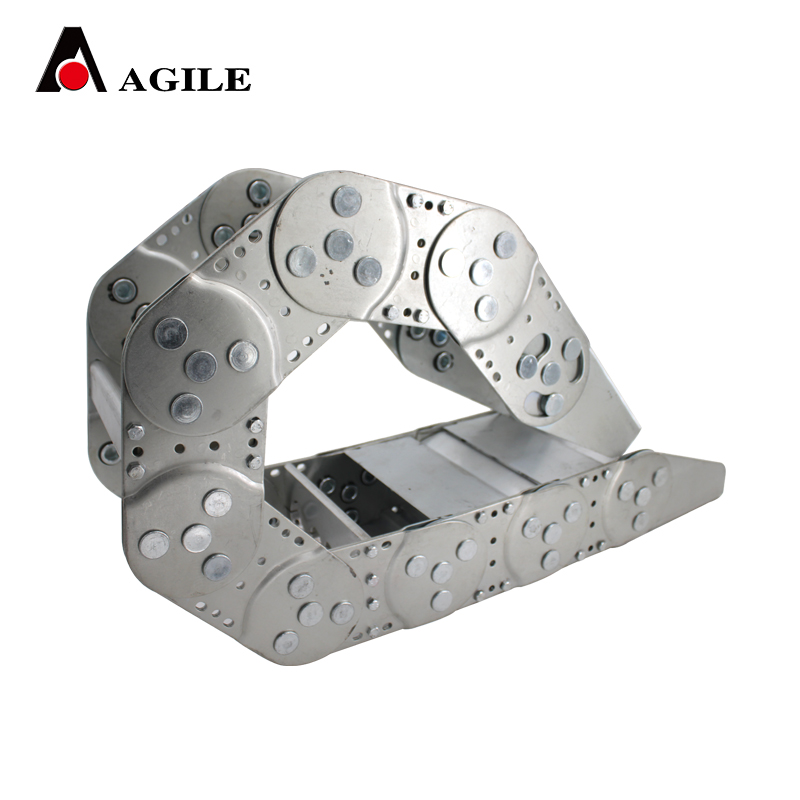

open drag chain

Understanding Open Drag Chains in Industrial Applications

Open drag chains, also known as cable carriers or drag links, play a crucial role in various industrial settings, particularly in the fields of automation and robotics. These components serve as protective conduits for moving cables, hoses, and wires, ensuring that they remain organized and free from wear and damage during operation. In this article, we will delve into the significance, design, and applications of open drag chains.

Open drag chains are typically designed in a segmented manner, allowing for easy installation and maintenance. Unlike traditional cable management solutions, open drag chains provide a clear view of the internal components, which makes it easier to identify any issues that may arise. This transparency not only streamlines troubleshooting but also enhances the overall safety of equipment by reducing the risk of tangling or snagging.

One of the primary advantages of open drag chains is their ability to accommodate a wide range of cables and hoses of varying sizes and materials. This versatility makes them suitable for different applications, from CNC machines to automatic assembly lines. The flexibility in design allows them to adapt to various movement patterns, whether linear or rotational, ensuring that the cables within remain intact and functional.

open drag chain

In addition to their organizational benefits, open drag chains are engineered to withstand the rigors of industrial environments. They are constructed from durable materials such as high-strength plastics or metals, enabling them to resist wear, tear, and harsh environmental conditions. Some drag chains are also designed to be self-lubricating, further extending their lifespan and reducing maintenance needs.

The installation of open drag chains can significantly reduce the time required for cable management in complex machinery. With their modular designs, users can easily modify or expand existing setups without extensive downtime. This adaptability is particularly beneficial in industries where production speeds and efficiency are paramount. Moreover, open drag chains contribute to the overall aesthetics of machinery by providing a neat and orderly appearance, which can enhance the workplace environment.

Open drag chains find applications in a multitude of sectors, including manufacturing, automotive, and aerospace industries. They are particularly useful in automated systems where dynamic movements are required. By effectively managing the cables, open drag chains help to minimize downtime caused by equipment failure, thereby increasing productivity and cost efficiency.

In conclusion, open drag chains are indispensable components in modern industrial applications. Their ability to provide protection, organization, and adaptability makes them a preferred choice for many engineers and technicians. As technology continues to advance, the design and functionality of open drag chains will likely evolve, further enhancing the efficiency and safety of automated systems in the industrial landscape.