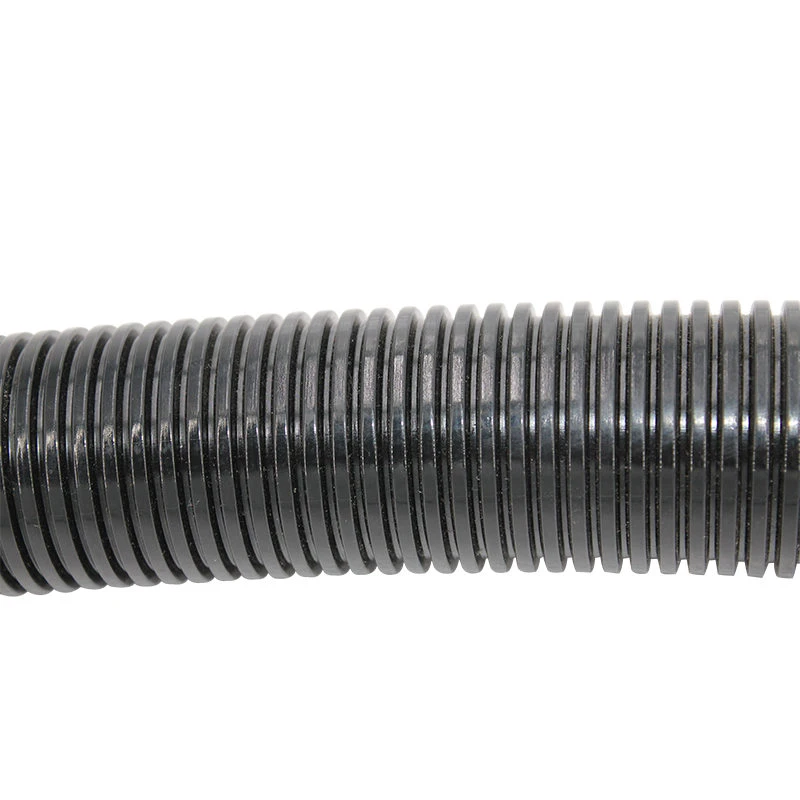

nylon corrugated tube

Nylon corrugated tubes are integral components in many industries, offering a unique blend of durability, flexibility, and resistance to a variety of environmental stresses. These tubes are particularly valued in sectors like automotive, electrical, and industrial machinery, demonstrating an impressive adaptability to different operational needs.

On the topic of sustainability, nylon corrugated tubes are often produced with a focus on environmental responsibility. Many manufacturers are adopting recycled materials in their production processes, aligning with global trends towards environmental sustainability. This not only reduces the carbon footprint associated with production but also appeals to eco-conscious industries seeking to minimize environmental impact. Maintenance of nylon corrugated tubes is minimal but important. Regular inspection for wear and tear, especially in high-stress environments, ensures that any potential issues are addressed promptly before escalating into more serious problems. Additionally, periodic cleaning of the tubes helps maintain their appearance and prevent clogging due to dust or debris, which could affect performance. Given their widespread applications and proven efficiency, research and development into nylon corrugated tubes continue, aiming to further enhance their properties and applicability. Innovations such as improved resistance to ultraviolet radiation and extreme temperatures are underway, potentially opening up new avenues for their use in even more challenging environments. In summary, nylon corrugated tubes offer an unmatched combination of strength, flexibility, and resistance against mechanical, electrical, and chemical stresses. Their ease of use, combined with sustainable production processes, makes them an exemplary choice for industries ranging from automotive to industrial machinery. As technology evolves and demands increase, these tubes are likely to continue playing a crucial role in protecting vital systems worldwide, standing as a testament to their enduring utility and efficiency. Investing in high-quality nylon corrugated tubes ensures not only enhanced performance and protection but also a commitment to durability and sustainability in industrial applications.

On the topic of sustainability, nylon corrugated tubes are often produced with a focus on environmental responsibility. Many manufacturers are adopting recycled materials in their production processes, aligning with global trends towards environmental sustainability. This not only reduces the carbon footprint associated with production but also appeals to eco-conscious industries seeking to minimize environmental impact. Maintenance of nylon corrugated tubes is minimal but important. Regular inspection for wear and tear, especially in high-stress environments, ensures that any potential issues are addressed promptly before escalating into more serious problems. Additionally, periodic cleaning of the tubes helps maintain their appearance and prevent clogging due to dust or debris, which could affect performance. Given their widespread applications and proven efficiency, research and development into nylon corrugated tubes continue, aiming to further enhance their properties and applicability. Innovations such as improved resistance to ultraviolet radiation and extreme temperatures are underway, potentially opening up new avenues for their use in even more challenging environments. In summary, nylon corrugated tubes offer an unmatched combination of strength, flexibility, and resistance against mechanical, electrical, and chemical stresses. Their ease of use, combined with sustainable production processes, makes them an exemplary choice for industries ranging from automotive to industrial machinery. As technology evolves and demands increase, these tubes are likely to continue playing a crucial role in protecting vital systems worldwide, standing as a testament to their enduring utility and efficiency. Investing in high-quality nylon corrugated tubes ensures not only enhanced performance and protection but also a commitment to durability and sustainability in industrial applications.