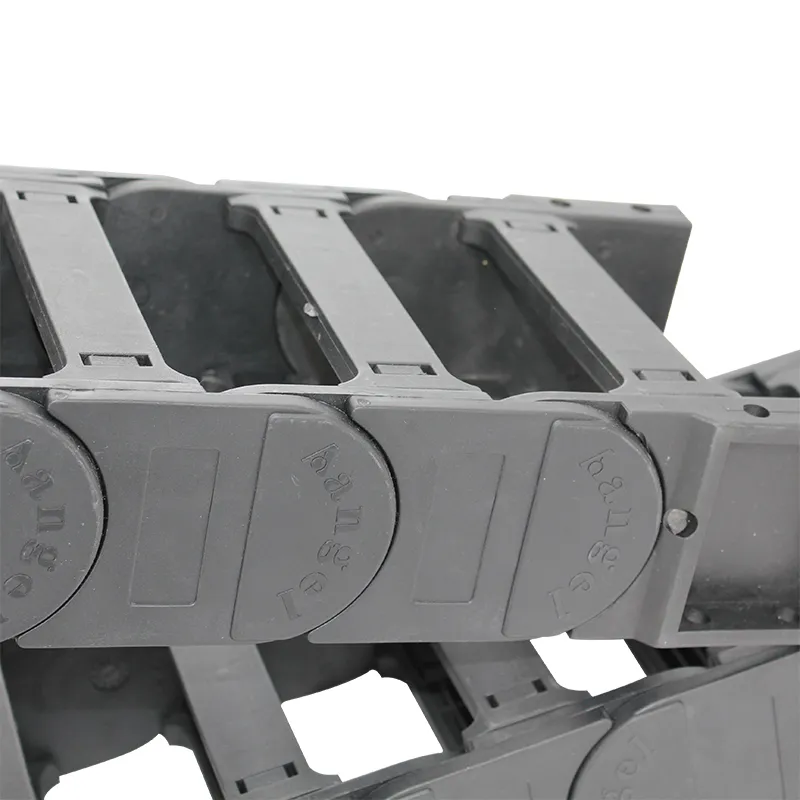

nylon cable carrier

Nylon cable carriers, often a pivotal component in the field of cable management and automation, have revolutionized the way industries handle cables and hoses in dynamic environments. Their lightweight yet durable structure provides an optimal solution for reducing wear and tear on cables, thus ensuring longevity and operational efficiency.

Moreover, trustworthiness is a crucial factor that manufacturers of nylon cable carriers emphasize. Leading manufacturers often subject their products to extensive testing under simulated real-world conditions to validate their performance metrics, such as tensile strength, UV resistance, and load capacity. This rigorous testing regime ensures that the carriers can meet diverse application needs without failure. Additionally, comprehensive warranties and technical support provided by credible manufacturers further enhance the trust factor, providing peace of mind to businesses investing in these essential components. Furthermore, innovation in the design and engineering of nylon cable carriers continues to evolve. Advances in materials science and manufacturing processes have led to the development of carriers that are more efficient, sustainable, and easier to install. Such innovations include modular designs that allow for quick modifications and expansions, minimizing installation time and ensuring scalability for future needs. This adaptability demonstrates the forward-thinking approach of manufacturers, who are continuously working to meet the changing demands of modern industry. Finally, the integration of nylon cable carriers in automation systems underscores their critical role in ensuring seamless operations. By maintaining an organized and protected cable management system, these carriers contribute to the smooth functioning of automated machinery and equipment. This organization not only prevents cable abrasions and entanglements but also facilitates easy troubleshooting and maintenance, thereby extending the life of both the cables and the machines they serve. In conclusion, nylon cable carriers represent a blend of innovative engineering, expert design, and reliable performance. Their ability to adapt to varying industrial environments while providing robust protection ensures they remain integral to modern automation and cable management solutions. With ongoing advancements, they promise to meet the evolving needs of industries, underscoring their enduring relevance and authority in the field.

Moreover, trustworthiness is a crucial factor that manufacturers of nylon cable carriers emphasize. Leading manufacturers often subject their products to extensive testing under simulated real-world conditions to validate their performance metrics, such as tensile strength, UV resistance, and load capacity. This rigorous testing regime ensures that the carriers can meet diverse application needs without failure. Additionally, comprehensive warranties and technical support provided by credible manufacturers further enhance the trust factor, providing peace of mind to businesses investing in these essential components. Furthermore, innovation in the design and engineering of nylon cable carriers continues to evolve. Advances in materials science and manufacturing processes have led to the development of carriers that are more efficient, sustainable, and easier to install. Such innovations include modular designs that allow for quick modifications and expansions, minimizing installation time and ensuring scalability for future needs. This adaptability demonstrates the forward-thinking approach of manufacturers, who are continuously working to meet the changing demands of modern industry. Finally, the integration of nylon cable carriers in automation systems underscores their critical role in ensuring seamless operations. By maintaining an organized and protected cable management system, these carriers contribute to the smooth functioning of automated machinery and equipment. This organization not only prevents cable abrasions and entanglements but also facilitates easy troubleshooting and maintenance, thereby extending the life of both the cables and the machines they serve. In conclusion, nylon cable carriers represent a blend of innovative engineering, expert design, and reliable performance. Their ability to adapt to varying industrial environments while providing robust protection ensures they remain integral to modern automation and cable management solutions. With ongoing advancements, they promise to meet the evolving needs of industries, underscoring their enduring relevance and authority in the field.