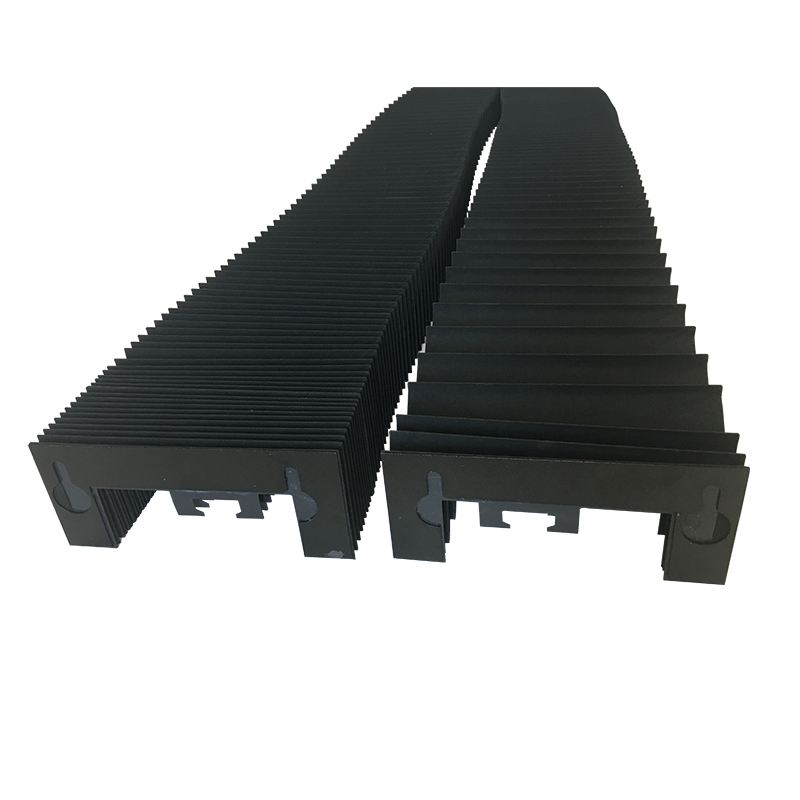

nylon cable carrier

The Versatility and Importance of Nylon Cable Carriers

In the modern age of technology and automation, the role of effective cable management cannot be overstated. Among the various solutions available, nylon cable carriers have emerged as a robust option that combines durability, flexibility, and lightweight characteristics, making them an essential component in various applications.

Nylon cable carriers, often referred to as energy chains or drag chains, are designed to protect and guide moving cables and hoses in machinery and automation systems. Their primary function is to ensure that electrical cables and pneumatic or hydraulic hoses do not snag or wear out due to constant movement. This is particularly critical in environments where dynamic motion occurs, such as conveyor systems, robotic arms, CNC machines, and various manufacturing equipment.

One of the standout features of nylon cable carriers is their exceptional strength and resilience. Crafted from high-quality nylon, these carriers can withstand harsh operating conditions, including exposure to oils, chemicals, and extreme temperatures. This durability is crucial in industrial settings where downtime can lead to significant financial losses. By using nylon cable carriers, companies can enhance the longevity of their cables and hoses, thereby reducing maintenance costs and increasing operational efficiency.

Another significant advantage of nylon cable carriers is their lightweight nature. Unlike traditional metal carriers that can add considerable weight to machinery, nylon carriers offer a much lighter alternative without compromising structural integrity. This characteristic is particularly beneficial in applications requiring high-speed motion or where weight reduction is paramount. In robotics, for example, using nylon carriers can contribute to improved performance and accuracy, as the reduction in weight allows for quicker movements and less strain on the joints of the robotic system.

nylon cable carrier

Flexibility is also a key element of nylon cable carriers. They are available in various designs and configurations to accommodate different sizes and types of cables and hoses. This versatility enables engineers and designers to tailor solutions to specific application needs, ensuring optimal performance. Moreover, nylon carriers can be easily modified or expanded, making them suitable for evolving technological demands.

The installation and maintenance of nylon cable carriers are relatively straightforward. Many products come with user-friendly features such as snap-open designs for easy access and internal guides for organized cable routing. This ease of use reduces installation time and labor costs, making nylon cable carriers an attractive option for manufacturers and engineers.

The growing trend towards automation and smart manufacturing further underscores the importance of nylon cable carriers in today’s technology landscape. As the need for intricate wiring solutions increases with the advent of advanced machinery and robotics, the demand for efficient cable management systems will continue to rise. Nylon cable carriers are poised to meet this demand, providing reliable protection and organization for cables in increasingly complex environments.

Furthermore, the sustainability aspect cannot be overlooked. Nylon is a material that can be recycled and repurposed, aligning well with the growing emphasis on environmentally friendly practices in manufacturing. By choosing nylon cable carriers, companies not only enhance operational efficiency but also contribute to sustainable practices.

In conclusion, nylon cable carriers serve as an indispensable solution in the realm of cable management, proving their value across various industries. With their durability, lightweight properties, flexibility, and ease of installation, they play a crucial role in protecting cables and hoses, thereby enhancing the efficiency and reliability of machinery and automated systems. As technology evolves, the significance of nylon cable carriers will only continue to grow, making them a vital component in the future of industrial applications. Businesses seeking to optimize their operations should certainly consider integrating nylon cable carriers into their design and manufacturing processes.