Non-Split Wire Loom Solutions for Effective Cable Management and Protection

Non-Split Wire Loom A Comprehensive Guide

In the world of automotive and electrical wiring, organization and protection are two crucial factors that contribute to the longevity and reliability of any electrical system. Among the numerous products designed for these purposes, non-split wire loom stands out as a popular choice for many DIY enthusiasts, professionals, and manufacturers alike. This article delves into the features, benefits, applications, and installation of non-split wire loom.

What is Non-Split Wire Loom?

Non-split wire loom, often simply referred to as wire loom, is a tubing that encases and protects wiring harnesses. Unlike split loom, which features a groove or split along its length allowing for easy insertion of wires, non-split loom is solid and offers complete coverage. It is typically made from materials like polyethylene or other polymers, which are designed to provide strength, flexibility, and resistance to environmental factors.

Features of Non-Split Wire Loom

1. Durability Non-split wire loom is highly resistant to abrasion and can withstand harsh conditions, making it ideal for use in automotive, marine, and industrial applications.

2. Flexibility Available in various diameters, non-split wire loom can accommodate different sizes of wires while providing flexibility to bend easily around corners and obstructions.

3. Protection By completely enclosing the wires, non-split wire loom protects against mechanical damage, moisture, and corrosive substances, which can extend the lifespan of the electrical system.

4. Neatness It helps in organizing and bundling wiring, resulting in a cleaner look and reducing the chances of tangles and confusion.

Benefits of Using Non-Split Wire Loom

1. Enhanced Safety Protecting wires from exposure reduces the risk of short circuits and electrical fires, ultimately ensuring the safety of the equipment and personnel.

2. Ease of Maintenance Organized wiring simplifies troubleshooting and repairs, making it easier to identify issues and service the electrical systems.

non split wire loom

4. Aesthetic Appeal A neat and organized wiring system looks more professional, which is particularly important in custom builds and installations.

Applications of Non-Split Wire Loom

Non-split wire loom finds a plethora of applications across various industries

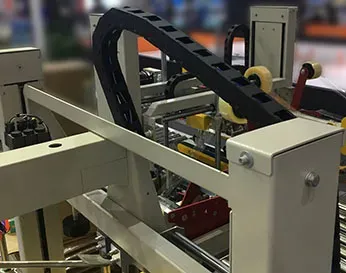

- Automotive Used extensively in vehicles to protect harnesses from heat, moisture, and abrasion. - Marine Ideal for boats and ships where exposure to saltwater and harsher conditions is common. - Industrial Employed in factories for machinery wiring, ensuring that electrical components are safeguarded against wear and tear. - Home Improvement Useful for home theater systems, computers, and other electronics, helping to keep wiring tidy and secure.

Installation of Non-Split Wire Loom

Installing non-split wire loom is straightforward and typically involves the following steps

1. Plan Your Wire Layout Before installing the loom, outline the route your wires will take. This will help in determining the lengths of loom needed.

2. Cut to Size Measure the length of wire bundles and cut the non-split loom to size. It’s essential to leave a little extra length to accommodate bends and connections.

3. Insert Wires Carefully insert the wires into the loom. Since non-split loom does not open, the wires must be fed through the end of the tubing, which may require some maneuvering.

4. Secure the Ends Use cable ties or electrical tape to secure the ends of the loom, preventing the wires from slipping out.

5. Positioning Finally, position the loom along the desired route, ensuring that it is not pinched or excessively bent in tight corners.

Conclusion

Non-split wire loom is an invaluable asset in various applications, providing protection, organization, and safety for electrical wiring. Its durability and ease of installation make it a preferred choice for both amateur and professional projects. Whether you are working on automotive systems, marine equipment, or home electronics, incorporating non-split wire loom into your wiring setup can ensure a clean, efficient, and lasting solution.