Understanding the Benefits of Non-Split Wire Looms for Cable Management Solutions

Understanding Non-Split Wire Loom A Comprehensive Guide

In the realm of electrical wiring and cable management, the term non-split wire loom frequently arises, especially among professionals and hobbyists involved in automotive, marine, and industrial applications. This versatile product holds significant importance for those seeking to protect, organize, and maintain the integrity of their wiring systems. In this article, we will delve into what non-split wire loom is, its benefits, applications, and installation tips.

What is Non-Split Wire Loom?

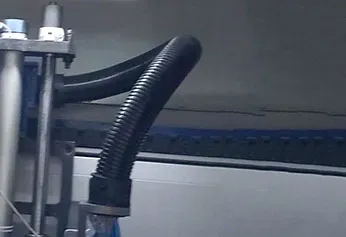

Non-split wire loom is a type of conduit used for protecting and organizing electrical wires. Unlike split wire loom, which has a slit along its length allowing for easy insertion and removal of wires, non-split wire loom is a solid tube that encases the entire wire bundle. This design offers enhanced protection against physical damage, chemicals, and abrasion, making it ideal for applications where wires are exposed to harsh conditions.

Benefits of Non-Split Wire Loom

1. Enhanced Protection Non-split wire loom provides a robust defense against environmental hazards, including oil, dirt, moisture, and UV rays. This is particularly beneficial in automotive and marine settings, where wires may be exposed to extreme weather or chemicals.

2. Durability Made from high-quality materials such as polyethylene or nylon, non-split wire loom is designed to withstand wear and tear. Its sturdy construction helps prevent fraying and damage, prolonging the life of your wires.

3. Neat Organization This type of loom helps maintain a tidy wiring setup. By bundling wires together, it reduces clutter and makes it easier to trace connections. This is especially useful in complex installations, where multiple wires may be present.

4. Ease of Installation Though it may require more effort to insert wires compared to split loom, non-split wire loom is relatively easy to work with. It can be cut to length, and the end can be sealed to prevent moisture ingress.

5. Versatility Non-split wire loom is available in various sizes and colors, accommodating different wire gauges and applications. This versatility makes it suitable for various industries, including automotive, aerospace, and industrial machinery.

Applications

Non-split wire loom is widely utilized across different sectors, reflecting its versatility and effectiveness. Here are a few common applications

- Automotive In vehicles, non-split wire loom is used to protect wiring harnesses from abrasion and damage due to engine vibration, heat, and exposure to road debris. It ensures that electrical systems function correctly, reducing the risk of failures.

non split wire loom

- Marine Boats and marine equipment often face harsh conditions, including saltwater exposure and extreme temperatures. Non-split wire loom is essential for protecting electrical systems in these environments, promoting safety and reliability.

- Industrial Equipment Manufacturing machines and industrial equipment use non-split wire loom to safeguard their wiring from mechanical wear and tear. This is crucial for maintaining operational efficiency and minimizing downtime.

- Home and DIY Projects For DIY enthusiasts and home improvement projects, non-split wire loom provides an effective solution for organizing electrical wiring within walls, attics, or basements. It enhances safety by reducing the chance of wires becoming damaged or entangled.

Installation Tips

Installing non-split wire loom can be straightforward if you follow some essential steps

1. Gather Materials Ensure you have all necessary materials, including the wire loom, cutting tools, and any additional protective elements like heat shrink tubing or grommets.

2. Measure and Cut Measure the length of wire loom needed, allowing for some extra length at both ends, and use a sharp utility knife to cut it to size.

3. Insert Wires Carefully insert the wires into the loom. If you are dealing with a large bundle of wires, it may be helpful to do this in sections.

4. Seal Ends To protect against moisture ingress, consider sealing the ends using heat shrink tubing or electrical tape.

5. Secure in Place Use zip ties or clips to secure the loom in place as needed, ensuring that it does not shift or rub against any sharp edges.

Conclusion

Non-split wire loom is an essential component in the electrical management toolkit, providing effective protection and organization for various applications. Whether in an automotive setting, marine environment, or industrial machinery, it enhances both safety and functionality. By understanding its benefits and learning the installation techniques, users can ensure their wiring systems remain protected and efficient for years to come.