Understanding the Benefits of Non-Split Wire Loom for Cable Management

Non-Split Wire Loom An Essential Tool for Cable Management

In today's fast-paced world, where technology permeates every aspect of our lives, efficient cable management is more critical than ever. Whether in automotive applications, general household setups, or industrial environments, the organization and protection of wires and cables ensure safety, longevity, and optimal functionality. One of the most effective solutions for cable management is the non-split wire loom.

What is Non-Split Wire Loom?

Non-split wire loom is a versatile plastic tubing designed to protect and organize wires and cables. Unlike split loom, which has a slit along its length for easy insertion of wires, non-split loom is a solid tube. This provides a more secure and protective enclosure for wires and is commonly made from durable materials such as polyethylene or nylon, offering resistance to abrasion, chemicals, and environmental factors.

Advantages of Using Non-Split Wire Loom

1. Protection The primary benefit of non-split wire loom is its ability to shield wires from physical damage. In environments where cables are subject to wear and tear, such as in automotive engines or industrial equipment, the solid protection offered by non-split loom helps prevent abrasion and reduces the risk of electrical shorts.

2. Organization Non-split wire loom allows for the bundling of multiple wires into a single, manageable tube. This organization not only improves the aesthetic of a wiring system but also simplifies troubleshooting and maintenance. An orderly setup makes it easier to identify and repair individual cables when issues arise.

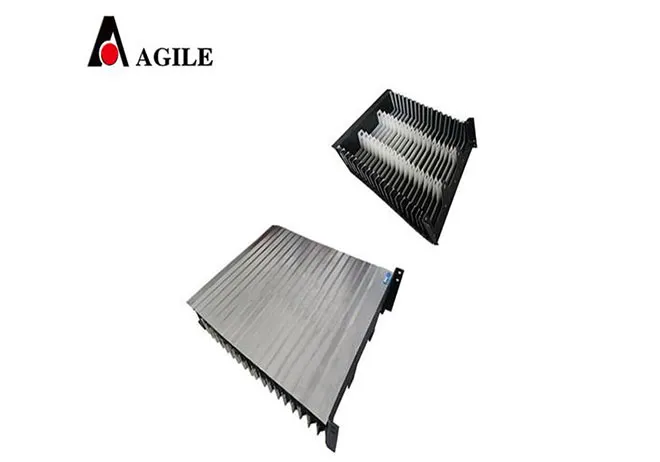

non split wire loom

3. Flexibility Despite being a solid piece of tubing, non-split wire loom retains a certain level of flexibility. This flexibility allows installers to maneuver and position the loom around tight corners and obstacles, ensuring that cables can be routed efficiently without undue stress that could lead to damage.

4. Temperature and Chemical Resistance Non-split wire looms are often designed to withstand various environmental conditions. Many types are UV resistant, making them suitable for outdoor applications, while others resist high temperatures or exposure to chemicals. This makes them ideal for use in diverse settings—from automotive to marine applications and industrial settings.

5. Ease of Installation Installing non-split wire loom is typically straightforward. It can be cut to desired lengths with basic tools, making it an accessible choice for DIY enthusiasts and professionals alike. Furthermore, securing the loom in place can be done with ties, clips, or adhesive, depending on the specific application.

When to Use Non-Split Wire Loom

Non-split wire loom is particularly beneficial in scenarios where maximum protection and organization are required. For instance, in automotive applications, where wires are exposed to engine heat, oil, and physical movement, non-split loom protects the integrity of critical wiring systems. In industrial environments, using non-split loom to manage cables enhances safety by reducing the risk of tripping hazards and simplifying maintenance access.

Conclusion

In conclusion, non-split wire loom is an invaluable tool for anyone looking to enhance their cable management strategies. Its durability, organization capabilities, and protective qualities make it suitable for a wide array of applications. By choosing non-split wire loom, individuals and businesses alike can ensure their wires and cables remain safe, organized, and efficient, ultimately contributing to the longevity and reliability of their electrical systems. Whether you are an automotive technician, a DIYer, or a facilities manager, considering the benefits of non-split wire loom can lead to a more streamlined and secure wiring system.