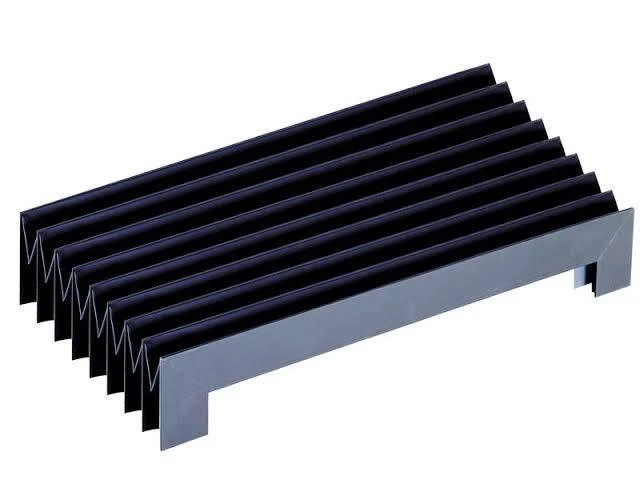

mini drag chain

Selecting the right drag chain size is crucial for ensuring optimal performance and longevity of your machinery. Drag chains, also known as cable carriers, play a vital role in protecting and guiding flexible cables and hoses attached to moving automated machinery. Incorrect sizing can lead to wear and tear, potential machinery breakdowns, or even hazardous situations. This article provides comprehensive insights into the factors influencing drag chain size selection, ensuring you make an informed choice that enhances operational efficiency.

Moreover, drag chain material plays a role in the size decision. While plastic drag chains are lightweight and cost-effective, they may not offer the durability necessary for heavy-duty environments. Conversely, steel drag chains offer strength but may require higher initial investment and maintenance. Make sure to choose a material that supports both your operational needs and budget constraints. Installation space must also be considered. Measure the available space accurately before choosing a drag chain to avoid retrofit issues. Some applications might require compact chains due to limited installation space, while others may allow for larger models, affording greater flexibility and room for future expansion. Finally, it's vital to work with a reliable supplier who can provide technical support and guidance tailored to your specific needs. Their expertise can play a crucial role in ensuring the drag chain selected will perform optimally throughout its lifecycle. By aligning with a trusted supplier, you not only gain access to quality products but also to a wealth of knowledge and support that immensely aids in installation and maintenance. In conclusion, selecting the right drag chain size demands a thorough analysis of various factors including cable dimensions, bend radius, fill weight, environmental conditions, material choice, and installation space. By meticulously assessing these elements, companies can ensure they are equipped with the most efficient and safe drag chains, thereby minimizing downtime and maximizing productivity.

Moreover, drag chain material plays a role in the size decision. While plastic drag chains are lightweight and cost-effective, they may not offer the durability necessary for heavy-duty environments. Conversely, steel drag chains offer strength but may require higher initial investment and maintenance. Make sure to choose a material that supports both your operational needs and budget constraints. Installation space must also be considered. Measure the available space accurately before choosing a drag chain to avoid retrofit issues. Some applications might require compact chains due to limited installation space, while others may allow for larger models, affording greater flexibility and room for future expansion. Finally, it's vital to work with a reliable supplier who can provide technical support and guidance tailored to your specific needs. Their expertise can play a crucial role in ensuring the drag chain selected will perform optimally throughout its lifecycle. By aligning with a trusted supplier, you not only gain access to quality products but also to a wealth of knowledge and support that immensely aids in installation and maintenance. In conclusion, selecting the right drag chain size demands a thorough analysis of various factors including cable dimensions, bend radius, fill weight, environmental conditions, material choice, and installation space. By meticulously assessing these elements, companies can ensure they are equipped with the most efficient and safe drag chains, thereby minimizing downtime and maximizing productivity.