mini drag chain

Understanding the Importance of Mini Drag Chains in Modern Machinery

In the realm of engineering and machinery, the significance of effective cable management cannot be overstated. One of the key components that facilitate this management is the mini drag chain. These innovative structures play a pivotal role in ensuring the smooth operation of machinery across various industries, from robotics to manufacturing and automation. This article delves into the features, applications, and advantages of mini drag chains, shedding light on why they are essential in modern-day operations.

What is a Mini Drag Chain?

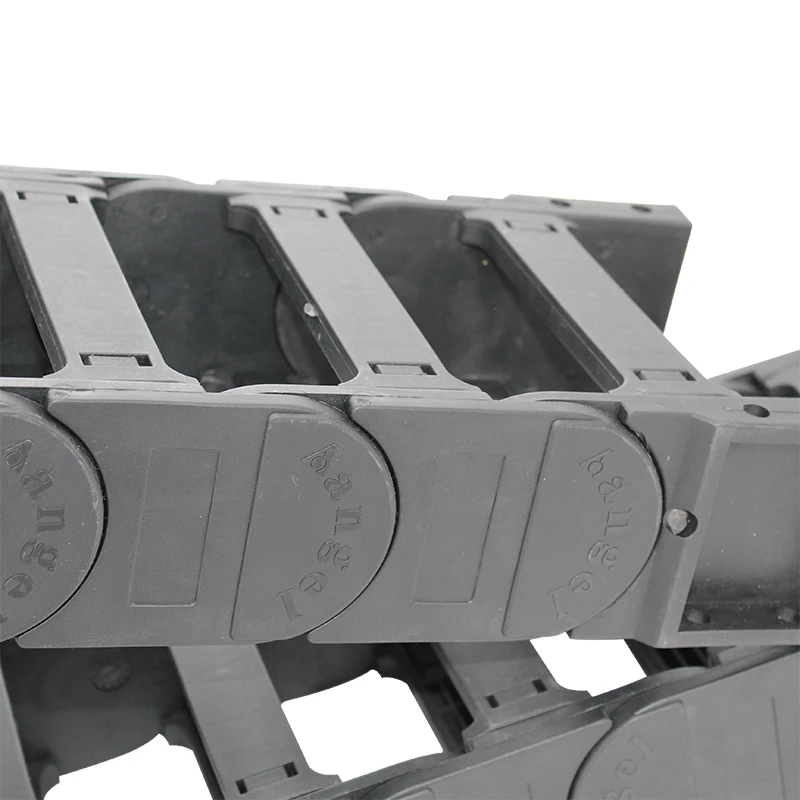

A mini drag chain, also known as a cable carrier or energy chain, is a flexible conduit that houses and protects moving cables, hoses, and other conductive elements in machinery. Designed to withstand bending, twisting, and flexing, these drag chains are essential for guiding cables or hoses along defined paths, especially in dynamic environments where motion is constant. Mini drag chains are characterized by their compact size and lightweight design, making them ideal for applications where space is a premium.

Features of Mini Drag Chains

Mini drag chains come with several features that enhance their functionality. Firstly, they are made from various materials, including plastic and metal, which offer different degrees of durability and flexibility. The plastic versions are lightweight and resistant to corrosion, making them suitable for indoor use or environments with minimal exposure to harsh conditions. Metal drag chains, on the other hand, provide greater strength and durability, ideal for heavy-duty applications.

Additionally, mini drag chains typically feature detachable links, allowing for easy installation and maintenance. The modular design enables users to customize the length and configuration according to their specific needs. Furthermore, many mini drag chains come with integrated channels or separators that help keep the cables organized and prevent wear due to friction or abrasion.

Applications of Mini Drag Chains

mini drag chain

The versatility of mini drag chains makes them suitable for a broad range of applications. One prominent use is in robotic systems, where precision and reliability are critical. In robotic arms, for instance, mini drag chains help manage the cables responsible for power supply and signal transmission, ensuring that they do not tangle or become damaged during the machine’s movements.

In the manufacturing sector, mini drag chains are commonly found in conveyor systems. They facilitate the guided movement of electrical and pneumatic hoses, contributing to the efficiency and safety of assembly lines. Additionally, they are prevalent in CNC machines and 3D printers, where effective cable management is crucial to maintain operational integrity and prevent disruptions.

Advantages of Using Mini Drag Chains

The adoption of mini drag chains in various industrial applications presents numerous advantages. Firstly, they significantly reduce the risk of cable damage, which can lead to costly downtimes and repairs. By keeping cables organized and preventing excessive bending, drag chains enhance the lifespan of the cables housed within them.

Moreover, mini drag chains improve the overall efficiency of machinery. They minimize the chances of entanglement and friction, allowing machines to operate smoothly and without interruption. This streamlined operation contributes to increased productivity and can lead to reduced operational costs.

Another important benefit is safety. Exposed cables and hoses pose a risk of tripping or snagging, which can be hazardous in busy work environments. By housing these elements within a mini drag chain, the risk of accidents is significantly lowered, promoting a safer workspace.

Conclusion

In conclusion, mini drag chains are indispensable components in modern machinery, offering solutions to cable management challenges across various industries. Their compact design, durability, and versatility make them an essential tool for improving efficiency, safety, and the longevity of equipment. As technology continues to advance, the role of mini drag chains will undoubtedly remain crucial, ensuring that our machines operate smoothly in an increasingly complex world. Investing in high-quality mini drag chains can ultimately lead to significant improvements in productivity and cost-effectiveness in industrial operations.