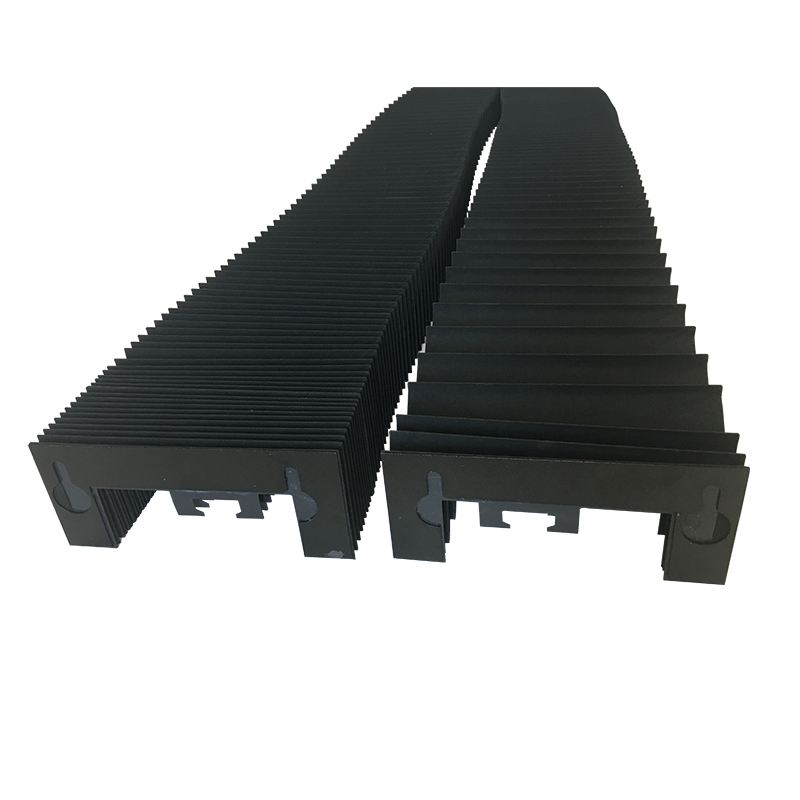

Compact Drag Chain for Efficient Cable Management and Organization

Understanding Mini Drag Chains Efficient Cable Management Solutions

In the world of modern machinery and automated systems, cable management has become a critical component for ensuring the seamless operation of equipment. One of the innovative solutions that have gained traction is the mini drag chain. This component plays a vital role in organizing and protecting cables, hoses, and wires, thereby enhancing operational efficiency and reducing maintenance needs. This article will explore what mini drag chains are, their benefits, applications, and considerations for selecting the right one.

What is a Mini Drag Chain?

A mini drag chain, often referred to as a cable drag chain or energy chain, is a modular component designed to guide and protect flexible cables and hoses in machinery. These chains consist of alternating links that create a channel where cables can run freely without the risk of tangling or damage. They are typically constructed from durable materials such as plastic or metal, providing a combination of flexibility and strength. The mini designation indicates that these chains are designed for smaller applications, making them suitable for compact and limited spaces where traditional drag chains may be too bulky.

Benefits of Mini Drag Chains

1. Effective Cable Management Mini drag chains streamline cable and hose organization, preventing them from getting tangled or damaged during operation. This organized approach reduces wear and extends the lifespan of electrical and hydraulic components.

2. Protection from Environmental Factors These chains protect cables from various environmental factors, including dust, oil, and mechanical wear. This is particularly important in settings like factories and workshops where equipment is exposed to harsh conditions.

3. Improved Safety By enclosing cables and hoses, mini drag chains help reduce the risks of tripping hazards and electrical shorts. This creates a safer working environment for operators and maintenance personnel.

4. Enhanced Mobility The design of mini drag chains allows for significant movement, enabling equipment to operate smoothly while providing the necessary flexibility. This is important in applications where machinery needs to move along multiple axes.

5. Easier Installation and Maintenance Modular designs of mini drag chains make them easy to install, modify, or replace. Maintenance is simplified since cables can be accessed without disassembling large sections of the machinery.

Applications of Mini Drag Chains

Mini drag chains are versatile and can be employed across a multitude of applications, including

mini drag chain

- CNC Machines In computer numerical control (CNC) machines, mini drag chains help manage the numerous cables and hoses essential for machine operation. - Robotics In robotic applications, these chains guide power and control cables while allowing for intricate movements without interference.

- Automated Guided Vehicles (AGVs) AGVs rely on mini drag chains to keep wiring organized while navigating various paths in warehouses and manufacturing facilities.

- Medical Equipment In medical devices, mini drag chains are crucial for protecting sensitive wires and ensuring reliable functionality.

Selecting the Right Mini Drag Chain

When considering the use of mini drag chains, several factors must be evaluated to ensure optimal performance

1. Size and Dimensions The chain should fit within spatial constraints while providing adequate room for the number of cables or hoses required.

2. Load Capacity It's essential to assess the weight and flexibility of the cables or hoses being housed, ensuring that the drag chain can support them without failure.

3. Material Choose a material that matches the environmental conditions, such as exposure to chemicals or extreme temperatures.

4. Bending Radius The bending radius of the chain is crucial, especially in applications involving frequent movement. A tighter radius could lead to premature wear on cables.

5. Ease of Maintenance Consider designs that allow for easy access and replacement of cables should maintenance be necessary.

Conclusion

Mini drag chains offer an effective and innovative solution for cable management in various industries. Their compact design, combined with the ability to protect and organize cables, makes them an invaluable component of modern machinery. By carefully selecting the appropriate mini drag chain for specific applications, businesses can enhance operational efficiency, reduce downtime, and create safer environments for their workers. As technology continues to advance, the role of mini drag chains will undoubtedly become even more significant in the evolution of automation and machinery.