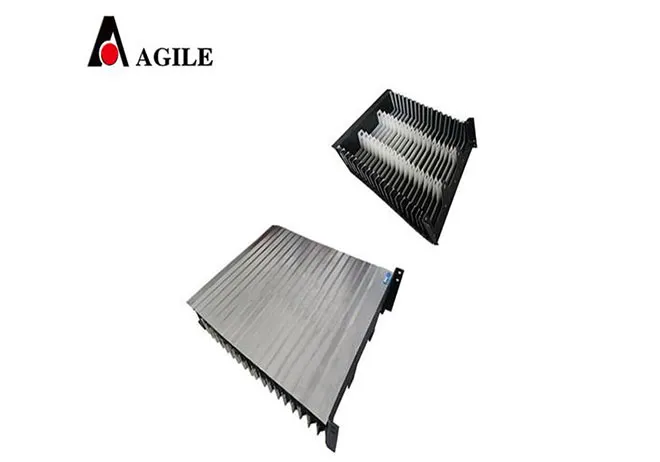

milling machine bellows

Understanding the importance of milling machine bellows begins with recognizing their role in protecting sensitive machine components from external factors, ensuring smooth operation and longevity. Milling machines, known for their precision and reliance on intricate moving parts, face constant threats from dust, debris, and coolant fluids. Bellows play a critical role in shielding crucial components like lead screws, machine ways, and sensors from these contaminants.

From an authority viewpoint, established manufacturers of milling machine bellows emphasize rigorous quality controls and testing standards. This ensures product reliability, particularly for industries where precision is paramount, like aerospace or medical device manufacturing. Institutional endorsements and compliance with international standards, such as ISO certifications, further reinforce the credibility and authority of these products in the market. Trustworthiness is another critical aspect facilitated by transparent customer service and comprehensive warranty plans offered by reputable suppliers. These organizations provide not just products, but ongoing support through installation guidance and maintenance advice, fostering long-term client relations. For businesses focusing on heavy machining, investing in premium-quality bellows serves as a wise operational strategy. Choosing the right bellows involves collaborating closely with suppliers for customized solutions tailored to specific machinery setups and operational conditions. This approach ensures tailored protection, significantly reducing the risks associated with component exposure to harmful external elements. In conclusion, the integration of milling machine bellows into industrial machinery is non-negotiable for facilities aiming to optimize efficiency, maintain precise output quality, and reduce operational costs. By offering a shield against the diverse threats presented by industrial environments, bellows stand as silent, yet crucial, sentinels that safeguard the integrity and performance of milling operations. Their significance extends beyond mere protection, representing a commitment to sustaining machinery excellence and operational reliability over time.

From an authority viewpoint, established manufacturers of milling machine bellows emphasize rigorous quality controls and testing standards. This ensures product reliability, particularly for industries where precision is paramount, like aerospace or medical device manufacturing. Institutional endorsements and compliance with international standards, such as ISO certifications, further reinforce the credibility and authority of these products in the market. Trustworthiness is another critical aspect facilitated by transparent customer service and comprehensive warranty plans offered by reputable suppliers. These organizations provide not just products, but ongoing support through installation guidance and maintenance advice, fostering long-term client relations. For businesses focusing on heavy machining, investing in premium-quality bellows serves as a wise operational strategy. Choosing the right bellows involves collaborating closely with suppliers for customized solutions tailored to specific machinery setups and operational conditions. This approach ensures tailored protection, significantly reducing the risks associated with component exposure to harmful external elements. In conclusion, the integration of milling machine bellows into industrial machinery is non-negotiable for facilities aiming to optimize efficiency, maintain precise output quality, and reduce operational costs. By offering a shield against the diverse threats presented by industrial environments, bellows stand as silent, yet crucial, sentinels that safeguard the integrity and performance of milling operations. Their significance extends beyond mere protection, representing a commitment to sustaining machinery excellence and operational reliability over time.