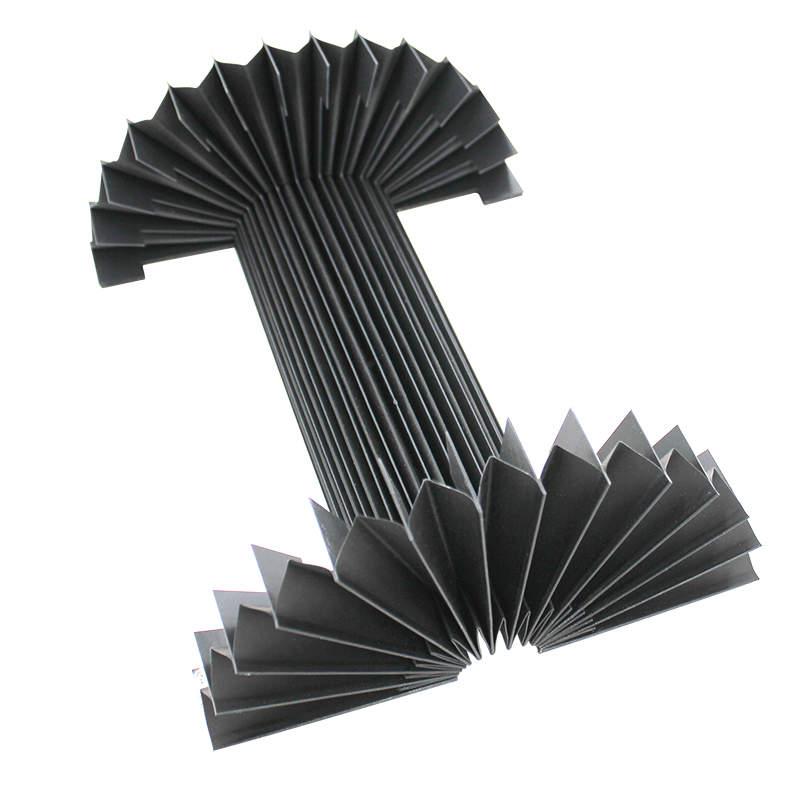

milling machine bellows

The Importance of Bellows in Milling Machines

Milling machines are essential tools in the manufacturing industry, known for their precision and versatility. They are used to shape metal and other materials into complex components, making them indispensable in various sectors, from automotive to aerospace. One often-overlooked component that plays a crucial role in the performance and longevity of milling machines is the bellows.

What Are Bellows?

Bellows are flexible, expandable components made from materials such as rubber, fabric, or plastic. They are designed to protect sensitive machine parts from dust, debris, and coolant exposure, which can lead to wear and tear. In milling machines, bellows serve as covers for moving parts, such as the vertical and horizontal axes, safeguarding them from environmental factors and contaminants during operation.

The Role of Bellows in Milling Machines

1. Protection Against Debris Milling machines operate in environments where chips, dust, and coolant are prevalent. These particles can easily infiltrate critical components, leading to degradation and potential failure of the machine. Bellows act as a shield, preventing harmful materials from entering the intricate mechanisms of the machine. They help maintain the integrity of sensitive components like linear guides and ball screws, which are pivotal for achieving precision milling.

milling machine bellows

2. Mitigation of Coolant Damage The use of coolant is common during the milling process to dissipate heat and prolong tool life. However, coolant can also cause damage if it seeps into the machine’s electrical components or bearings. Bellows provide a barrier against coolant exposure, ensuring that vital parts remain dry and functioning optimally.

3. Enhanced Machine Longevity By safeguarding against debris and coolant intrusion, bellows significantly enhance the longevity of milling machines. Equipment that is well-protected from environmental stresses experiences less wear, reducing the need for repairs and replacements. This not only saves manufacturers money in the long run but also increases uptime and productivity.

4. Safety Considerations In addition to their protective roles, bellows also contribute to safety in milling operations. By containing debris and preventing it from escaping the machine, bellows help minimize the risk of operator injury. Furthermore, properly functioning bellows can reduce noise levels during operation, contributing to a safer and more comfortable workplace.

5. Maintenance and Replacement Maintaining bellows is crucial for their effectiveness. Regular inspections for signs of wear, such as cracks or tears, can help catch issues before they become serious problems. Replacement bellows are readily available, and using high-quality materials ensures optimal performance. Manufacturers should choose bellows designed specifically for their milling machines, taking into account factors such as size, material, and application.

Conclusion

In conclusion, bellows are a vital component of milling machines that should not be overlooked. Their primary functions—protecting against debris, mitigating coolant damage, enhancing longevity, and ensuring safety—make them essential for the efficient operation of milling equipment. Investing in high-quality bellows and committing to regular maintenance can lead to significant benefits in terms of productivity, safety, and cost-efficiency. As technology continues to advance, the role of bellows will only become more critical in maintaining the performance standards expected in modern manufacturing environments. Manufacturers would do well to recognize the importance of this often-missed component in their milling machines.