High-Quality Milling Machine Bellows for Maximum Protection

Understanding Milling Machine Bellows A Critical Component in Precision Machining

Milling machines are essential in various manufacturing processes, known for their ability to shape materials with precision. Among the many components that contribute to the effective operation of these machines, milling machine bellows play a critical role in maintaining the integrity and longevity of the equipment.

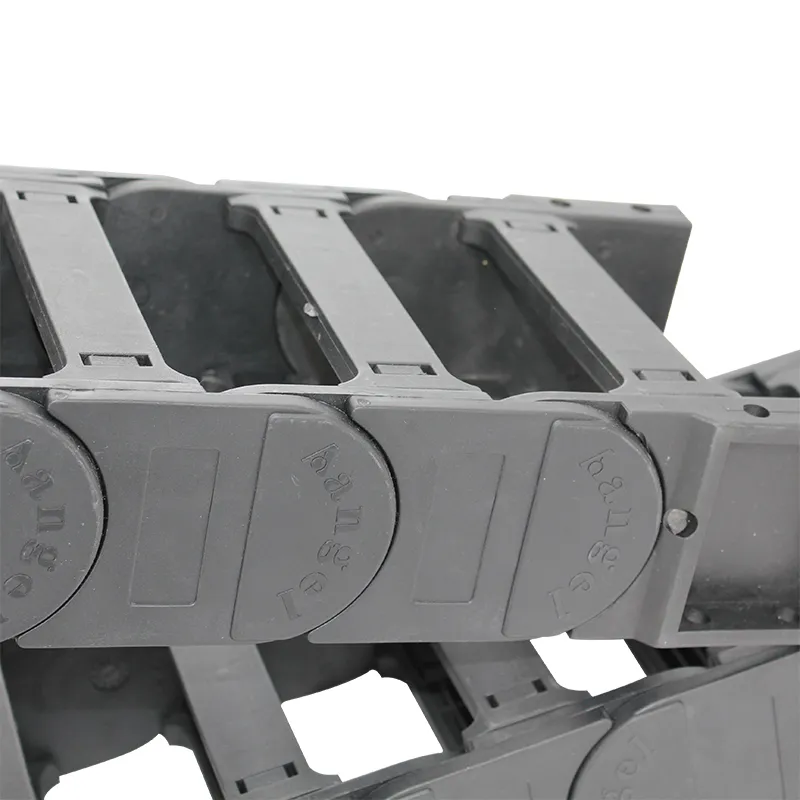

Bellows are flexible membrane structures designed to protect moving parts of the milling machine from debris, coolant, and other contaminants that can lead to mechanical failures. Typically made from materials such as rubber, fabric, or metal, these bellows are engineered to withstand both the physical demands of milling operations and the exposure to various chemicals.

One of the primary functions of milling machine bellows is to provide a barrier against chips and shavings produced during the milling process

. These byproducts can be highly abrasive, and if allowed to accumulate, can cause significant wear and tear on precision components, including guides and lead screws. By keeping these areas clean, bellows enhance the overall efficiency of the machine, allowing for more accurate cuts and extending the operational life of the equipment.milling machine bellows

Furthermore, bellows aid in protecting the internal workings of the milling machine from coolant and lubricants that are essential in many machining applications. These fluids serve to reduce friction and dissipate heat, but they can also attract grime and dirt. Bellows create a robust shield that prevents these substances from entering sensitive areas, ensuring that the machinery operates smoothly and reducing the frequency of maintenance required.

The design of milling machine bellows is crucial to their performance. They need to be flexible enough to accommodate the movements of the machine while remaining durable enough to withstand repeated use. Manufacturers often customize bellows to fit specific machine models, taking into account size, shape, and material requirements. This customization ensures that the milling machine operates at optimal efficiency, with minimal risk of contamination or mechanical failure.

In addition to their protective functions, the aesthetic aspect of milling machine bellows should not be overlooked. They often contribute to the overall appearance of the machine, giving it a cleaner and more professional look. This is particularly important in settings where machinery is visible to customers or stakeholders, as it reflects the quality and care of the operation.

In conclusion, milling machine bellows are an indispensable component in the realm of precision machining. They protect against debris and contaminants, enhance the efficiency and lifespan of milling equipment, and contribute to the overall functionality of the machinery. Understanding the importance of bellows can help operators make informed decisions regarding maintenance and upgrades, ultimately leading to better performance and productivity in their machining processes. By investing in high-quality bellows, manufacturers can ensure their milling machines remain in peak condition, ready to tackle any project with accuracy and reliability.