Innovative Metal Wire Track Design for Enhanced Performance and Durability

The Evolution of Metal Wire Tracks in Modern Applications

In recent years, the use of metal wire tracks has gained traction across various industries, primarily due to their versatility, durability, and cost-effectiveness. Wire tracks, commonly composed of materials such as stainless steel, aluminum, or copper, are crucial in several applications, spanning from manufacturing to transportation and even in the realm of technology. This article explores the evolution, benefits, and various applications of metal wire tracks.

Understanding Metal Wire Tracks

Metal wire tracks are essentially pathways made from wires that allow the movement of items, cables, or even people. These tracks can vary in complexity—from simple guide wires to sophisticated conveyor belts utilized in automated systems. Their fundamental role is to facilitate smooth and efficient movement, reducing friction and enhancing the speed of movement.

Historical Perspective

The origins of wire tracks can be traced back to the industrial revolution when machinery began to dominate manufacturing processes. Early tracks were made of heavy-duty materials to withstand load and wear. However, as technology progressed, so did the design and materials used in wire tracks. The advent of lighter alloys, improved manufacturing techniques, and coatings for corrosion resistance allowed for more versatile and efficient designs.

Benefits of Metal Wire Tracks

1. Durability Unlike plastic or rubber alternatives, metal wire tracks offer superior strength and longevity. They can withstand extreme temperatures, abrasion, and chemical exposure, making them suitable for a wide range of environments.

2. Customization Wire tracks can be easily customized to fit specific needs. Manufacturers can adjust the dimensions, spacing, materials, and even coatings to adapt the tracks for particular applications.

3. Safety Metal wire tracks are generally safer than other materials, as they are less susceptible to wear and tear. This results in a lower risk of breakage that could lead to accidents in industrial environments.

4. Cost-Effective Although the initial investment might be higher, their durability and low maintenance costs make wire tracks a worthwhile investment in the long run. They are expected to have a longer service life compared to alternatives.

Applications Across Industries

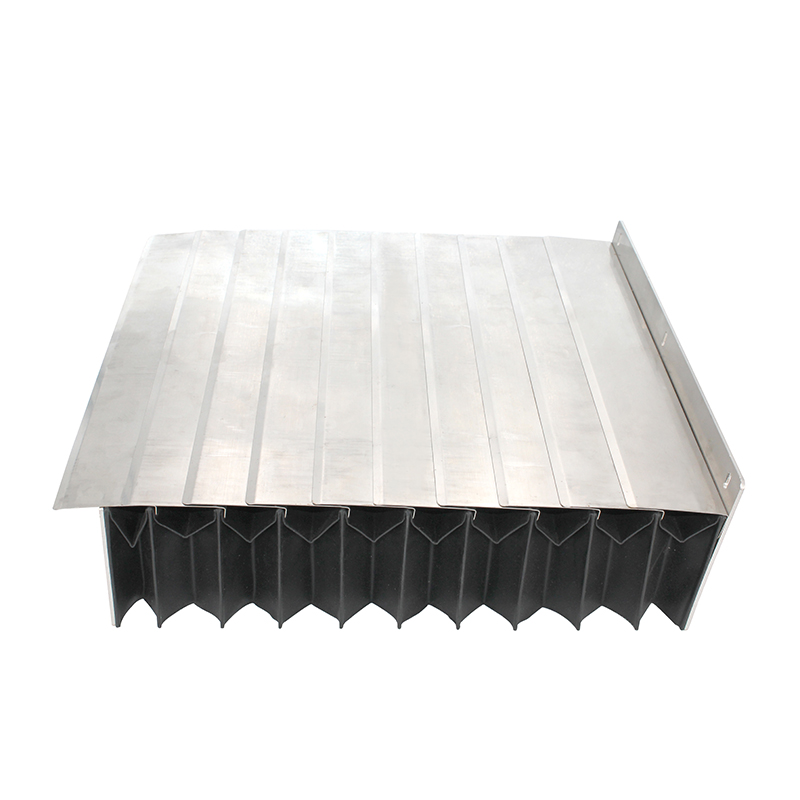

metal wire track

The applications of metal wire tracks are vast and diverse

- Manufacturing In manufacturing plants, wire tracks are often used in conveyor systems to transport materials from one station to another, facilitating efficient assembly lines.

- Automotive Industry Metal wire tracks are integral in various automotive applications, such as guiding parts during assembly or supporting wiring systems in vehicles, ensuring everything runs smoothly.

- Telecommunications In the telecommunications sector, metal wire tracks help organize and guide cables, contributing to efficient system management and ease of maintenance.

- Aerospace In aerospace applications, wire tracks ensure that critical systems are protected and organized, promoting safety and reliability in aircraft.

- Agriculture Precision farming often utilizes metal wire tracks in automated systems for planting, harvesting, and transporting produce, maximizing efficiency and productivity.

Innovations on the Horizon

As technology continues to evolve, so does the design and functionality of metal wire tracks. Innovations such as smart tracks equipped with sensors for monitoring load and movement patterns are emerging. These enhancements can provide real-time data, allowing for predictive maintenance and optimizing operations.

Furthermore, advancements in material science are leading to the development of lightweight, high-strength alloys that can significantly reduce energy consumption in transportation applications. The integration of environmental sustainability is also shaping the future of metal wire tracks, with a focus on recyclable materials and eco-friendly manufacturing processes.

Conclusion

Metal wire tracks represent an essential component across numerous industries, adapting and evolving to meet modern demands. Their resilience, customizable nature, and versatility make them indispensable in enhancing efficiency and productivity. As technology progresses, the applications and innovations surrounding metal wire tracks will likely expand, paving the way for smarter, more efficient systems that can handle the complexities of the modern world.