metal drag chain

Understanding Metal Drag Chains An Essential Component in Modern Machinery

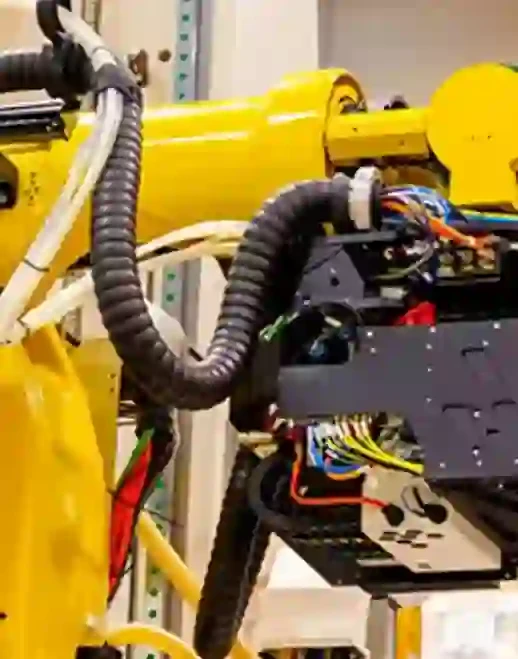

In today’s rapidly advancing industrial landscape, the efficiency and reliability of machinery play a pivotal role in productivity. One essential yet often overlooked component that facilitates smooth operations in various applications is the metal drag chain. These innovative structures are engineered to manage cables and hoses, protecting them from wear and tear while maintaining mobility and organization.

What is a Metal Drag Chain?

A metal drag chain, also known as cable carrier or drag chain, is a flexible and durable solution designed to guide and protect moving cables, hoses, or pipes in mobile applications. They are commonly used in environments where equipment undergoes repetitive movement, such as CNC machinery, robotic arms, or conveyor systems. Metal drag chains are constructed from various metals, including steel and aluminum, making them robust and capable of withstanding harsh conditions.

The Importance of Metal Drag Chains

One of the primary functions of metal drag chains is to protect cables and hoses from abrasion, which could lead to failures and, consequently, costly downtimes

. By using a drag chain, manufacturers can significantly prolong the lifespan of cables and hoses, thus enhancing the overall reliability of machinery. This protection is crucial in industries ranging from manufacturing and automation to automotive and aerospace, where any malfunction can result in major operational disruptions.Moreover, metal drag chains offer organization. In any environment where multiple cables or hoses are in use, the risk of tangling and damage is high. Metal drag chains neatly bundle these elements together, ensuring they are neatly arranged and easily accessible. This organization not only enhances functionality but also simplifies maintenance work, as technicians can quickly identify and address any issues.

Design and Customization

metal drag chain

Metal drag chains come in various designs and sizes to accommodate different applications. They can be categorized based on their mobility requirements, such as straight or curved paths. The chains can also be customized to fit specific needs regarding the number of channels, width, and height. Many manufacturers offer modular drag chains, allowing users to extend the chain length or modify it to include additional channels easily.

Another aspect of customization lies in the material choice. While steel offers excellent strength and durability, aluminum provides a lightweight alternative, making it ideal for applications where minimizing weight is essential. Additionally, numerous surfaces and finishes can be applied to metal drag chains to enhance their resistance to corrosion and environmental factors, tailoring them to specific working conditions.

Applications of Metal Drag Chains

The versatility of metal drag chains allows them to be employed across various sectors. In the manufacturing industry, for instance, they are instrumental in CNC machines and automated production lines where precise movements are paramount. In robotics, metal drag chains ensure that robotic arms function smoothly by providing unobstructed cable management.

Furthermore, the automotive industry benefits significantly from metal drag chains. They are employed in assembly lines where multiple tools and components move simultaneously, ensuring no tangling occurs. The aerospace sector also utilizes these chains within assembly robots and testing equipment, further emphasizing the importance of metal drag chains in high-precision environments.

Conclusion

In conclusion, metal drag chains play an indispensable role in the optimization of machinery and equipment across numerous industries. By protecting cables and hoses from damage while providing organization and mobility, they enhance the overall efficiency and reliability of operations. With advancements in design and materials, these chains will continue to evolve, adapting to the needs of modern-day applications. As industries strive for higher productivity and reduced downtime, the significance of metal drag chains will undoubtedly grow, marking them as vital components in the future of technology and manufacturing.