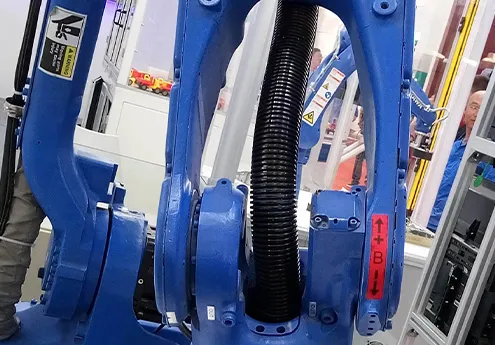

metal corrugated conduit

Searching for a durable, reliable solution to protect and route electrical wiring? Metal corrugated conduit offers a blend of flexibility, resilience, and safety, making it indispensable in a variety of industrial and residential applications. Below, we delve into the unique characteristics, benefits, and specialist advice on utilizing metal corrugated conduit, emphasizing real-world experiences that highlight its essentiality.

When it comes to authority in the field, regulatory bodies such as UL (Underwriters Laboratories) and NEC (National Electrical Code) certify metal corrugated conduits for various applications, guaranteeing that they meet stringent safety standards. An authenticated product not only ensures compliance but also builds trust with end-users, reassuring them of the reliability of their electrical systems. Trustworthiness, another pivotal factor in product selection, can be gauged through product reviews and testimonials from users across different sectors. Feedback from facility managers in manufacturing plants, for instance, reveals how metal corrugated conduits have excelled in minimizing downtime by offering unmatched durability and safety. This kind of third-party validation cements trust further, influencing purchasing decisions by providing empirical evidence of performance. In conclusion, metal corrugated conduit stands out as a superior choice for anyone seeking a protective solution for electrical wiring. The combination of professional expertise and real-world experiences underscores its unparalleled value proposition. Whether addressing safety concerns in hazardous settings or ensuring compliance with industry standards, this conduit remains a frontline choice for its blend of flexibility, durability, and protective capability. Leveraging its use not only aligns with best practices but also integrates a level of lasting trust and authority in maintaining robust electrical systems.

When it comes to authority in the field, regulatory bodies such as UL (Underwriters Laboratories) and NEC (National Electrical Code) certify metal corrugated conduits for various applications, guaranteeing that they meet stringent safety standards. An authenticated product not only ensures compliance but also builds trust with end-users, reassuring them of the reliability of their electrical systems. Trustworthiness, another pivotal factor in product selection, can be gauged through product reviews and testimonials from users across different sectors. Feedback from facility managers in manufacturing plants, for instance, reveals how metal corrugated conduits have excelled in minimizing downtime by offering unmatched durability and safety. This kind of third-party validation cements trust further, influencing purchasing decisions by providing empirical evidence of performance. In conclusion, metal corrugated conduit stands out as a superior choice for anyone seeking a protective solution for electrical wiring. The combination of professional expertise and real-world experiences underscores its unparalleled value proposition. Whether addressing safety concerns in hazardous settings or ensuring compliance with industry standards, this conduit remains a frontline choice for its blend of flexibility, durability, and protective capability. Leveraging its use not only aligns with best practices but also integrates a level of lasting trust and authority in maintaining robust electrical systems.