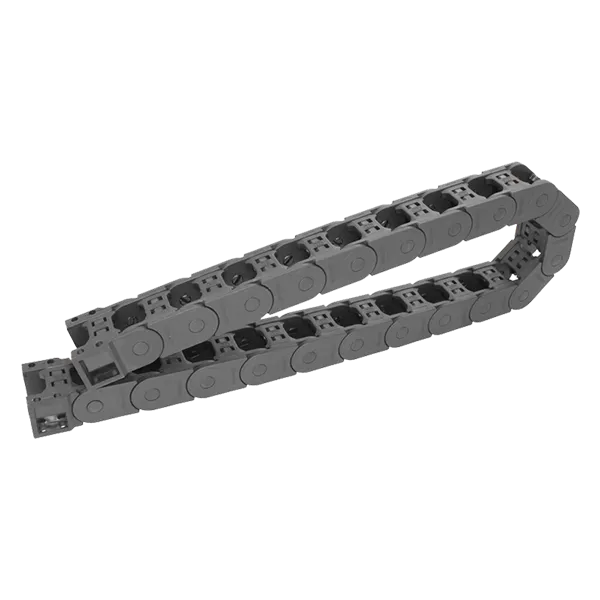

metal corrugated conduit

Understanding Metal Corrugated Conduits Benefits and Applications

Metal corrugated conduits are increasingly becoming a pivotal component in electrical installations and industrial applications. Their unique design and material properties offer distinctive advantages over traditional conduit options, making them the preferred choice in various environments.

What is a Metal Corrugated Conduit?

A metal corrugated conduit is a type of flexible metal conduit made from corrugated steel or aluminum, shaped into a series of alternating ridges and grooves. This configuration allows the conduit to be both flexible and durable, providing exceptional protection for electrical wiring against various environmental factors. The term corrugated refers to the way the metal is shaped, which enhances its structural integrity and flexibility.

Key Benefits of Metal Corrugated Conduits

1. Flexibility and Ease of Installation One of the most significant advantages of metal corrugated conduits is their flexibility. Unlike rigid conduits, which can be cumbersome and difficult to maneuver, corrugated conduits can easily bend around corners and fit into tight spaces. This flexibility not only simplifies installation but also reduces the need for additional fittings, ultimately saving both time and costs.

2. Durability and Strength Made from robust materials like aluminum or galvanized steel, metal corrugated conduits offer impressive durability. They are resistant to mechanical damage, corrosion, and harsh environmental conditions, making them ideal for outdoor installations or industrial settings where exposure to extreme temperatures, moisture, and chemicals is commonplace.

3. Protection Against External Influences Electrical wiring requires protection from several external factors such as heat, moisture, dust, and mechanical impacts. Metal corrugated conduits provide an effective barrier, safeguarding electrical conductors from damage and ensuring long-term reliability. This protective feature is crucial in applications involving heavy machinery, outdoor installations, and areas with high foot traffic.

4. Fire Resistance Unlike non-metallic options, metal conduits offer significant fire-resistance capabilities. In the event of a fire, metal conduits do not emit toxic fumes, providing a safer environment within buildings and industrial areas. This fire-resistant property is particularly important in settings such as factories, warehouses, and commercial buildings where hazardous materials may be present.

metal corrugated conduit

5. Electromagnetic Shielding In some applications, electromagnetic interference (EMI) can disrupt the performance of sensitive electronic equipment. Metal corrugated conduits provide excellent electromagnetic shielding, making them a suitable choice for installations involving data cables or other electronic components that require enhanced protection against interference.

Applications of Metal Corrugated Conduits

1. Industrial Settings Metal corrugated conduits are widely used in industrial settings for powering machinery and equipment. Their ability to withstand harsh conditions makes them ideal for factories, chemical plants, and mining operations.

2. Commercial Buildings In commercial buildings, these conduits are employed for electrical wiring systems, security systems, and HVAC installations. Their strength and flexibility allow for complex installations while maintaining a neat and organized appearance.

3. Outdoor Installations Whether it’s street lighting, signage, or outdoor electrical systems, metal corrugated conduits are designed to resist corrosion and environmental degradation. Their ability to handle different weather conditions makes them a reliable choice for outdoor applications.

4. Transportation Infrastructure Metal corrugated conduits are extensively used in transportation infrastructure projects, such as railways, highways, and airports. They protect vital electrical systems from environmental exposure, ensuring safe and efficient operations in these critical areas.

5. Marine Applications With the inherent exposure to saltwater and humidity, metal corrugated conduits are also suitable for marine applications. They provide enhanced protection for electrical systems on boats, ships, and offshore platforms.

Conclusion

Metal corrugated conduits represent a robust and versatile solution for a multitude of electrical installation needs. Their unique properties—combining flexibility, durability, and protective capabilities—make them an ideal choice for a wide range of applications, from industrial and commercial settings to outdoor and marine environments. As the demand for reliable and efficient electrical protection continues to grow, metal corrugated conduits will remain a key component in ensuring electrical safety and performance. Whether you are a contractor, engineer, or facility manager, understanding the benefits and applications of metal corrugated conduits will aid in making informed decisions that enhance your projects’ success.