metal corrugated conduit

Metal Corrugated Conduit A Versatile Solution for Electrical Protection

In the ever-evolving world of electrical installations, the need for robust, flexible, and durable conduits has become paramount. Among the various options available, metal corrugated conduit stands out as a preferred choice due to its unique properties and versatile applications. This article explores the nature, benefits, and applications of metal corrugated conduit, highlighting why it is an ideal solution for protecting electrical wiring.

Metal corrugated conduit, often made from materials such as galvanized steel or aluminum, is characterized by its distinct ribbed structure. This design not only provides flexibility but also enhances strength, making it capable of withstanding harsh environmental conditions. The corrugated surface allows the conduit to bend easily, accommodating tight spaces and complex routing in installations. This flexibility is particularly beneficial in industries where the layout may need to be adjusted frequently or where installations occur in tight or awkward spaces.

One of the foremost advantages of metal corrugated conduit is its robust protection against physical damage. Unlike non-metallic conduits, metal corrugated options are resistant to impacts, cuts, and abrasions. This characteristic is crucial in settings where equipment might be exposed to harsh handling or accidental impacts, such as manufacturing plants, warehouses, and outdoor installations. Furthermore, the metal construction offers fire resistance, ensuring that in the event of a fire, the chances of conduit melting or contributing to the fire’s spread are significantly reduced.

Another essential benefit of metal corrugated conduit is its ability to shield against electromagnetic interference (EMI). This is particularly important in environments where sensitive electronic equipment is used, such as data centers and laboratories. The conductive nature of metal provides a barrier against external electromagnetic fields, safeguarding the integrity of the signals carried by the wiring within the conduit. This feature ensures that installations remain efficient and reliable, minimizing downtime caused by interference.

metal corrugated conduit

The installation process of metal corrugated conduit is also relatively straightforward. Most are designed for easy joining and cutting, which can save time and labor costs during installation. Additionally, many metal conduits come with pre-fabricated fittings, making connections more accessible and stable. The flexibility and adaptability of corrugated conduits allow installers to maneuver them around obstacles, facilitating seamless integration into existing infrastructures.

In terms of sustainability, metal corrugated conduit holds an edge over many other types of conduits. Metal is recyclable and tends to have a longer lifespan compared to plastic alternatives. By investing in durable, metal conduits, businesses can contribute to an eco-friendly approach while also reducing the frequency of replacements and repairs, ultimately lowering long-term costs.

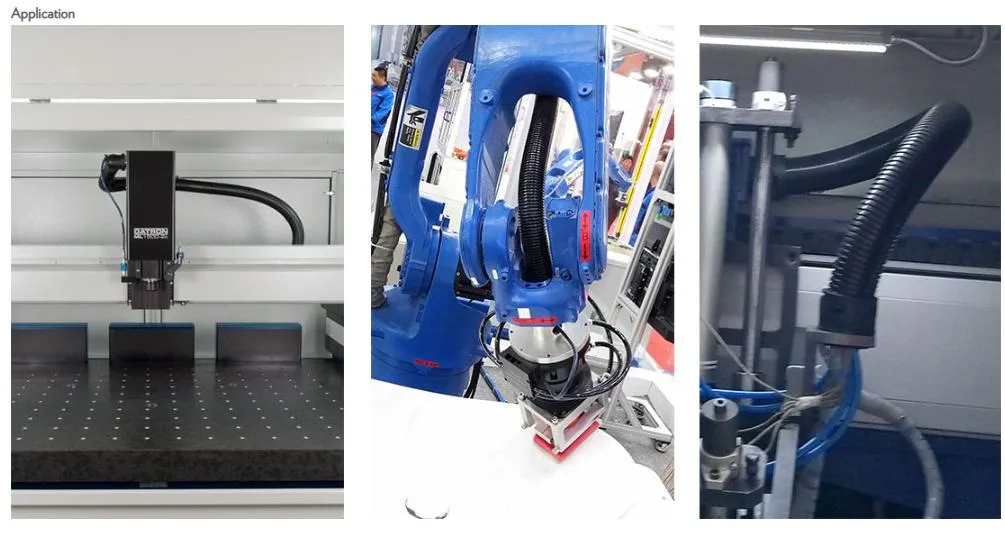

Application-wise, metal corrugated conduit finds its place in a plethora of industries. From industrial manufacturing to commercial buildings, and from telecommunications to automotive, these conduits are employed to protect and route electrical wiring systems. Their ability to endure extreme temperatures and corrosive environments makes them particularly popular in sectors like oil and gas, marine, and HVAC applications.

In conclusion, metal corrugated conduit presents a compelling solution for various electrical protection needs. Its combination of flexibility, strength, and resistance to environmental factors makes it a reliable choice for many industries. As technology progresses and the demand for innovative solutions continues to grow, metal corrugated conduit stands ready to meet the challenges of modern electrical installations, proving itself as an indispensable component in the reliability and safety of electrical systems.