metal chip conveyor systems

Metal Chip Conveyor Systems An Overview

In the realms of manufacturing and metalworking, efficiency and productivity are paramount. One critical component that facilitates these goals is the metal chip conveyor system. As industries increasingly focus on automation and streamlined operations, understanding the benefits and functionalities of metal chip conveyor systems becomes essential.

What Are Metal Chip Conveyor Systems?

Metal chip conveyor systems are specialized mechanisms designed to transport metal shavings, chips, and debris that are produced during machining processes. These systems are essential in industries such as automotive, aerospace, and general manufacturing, where cutting, grinding, and milling operations are prevalent. The efficient removal of metal chips contributes not only to operational efficiency but also to workplace safety and cleanliness.

Types of Metal Chip Conveyors

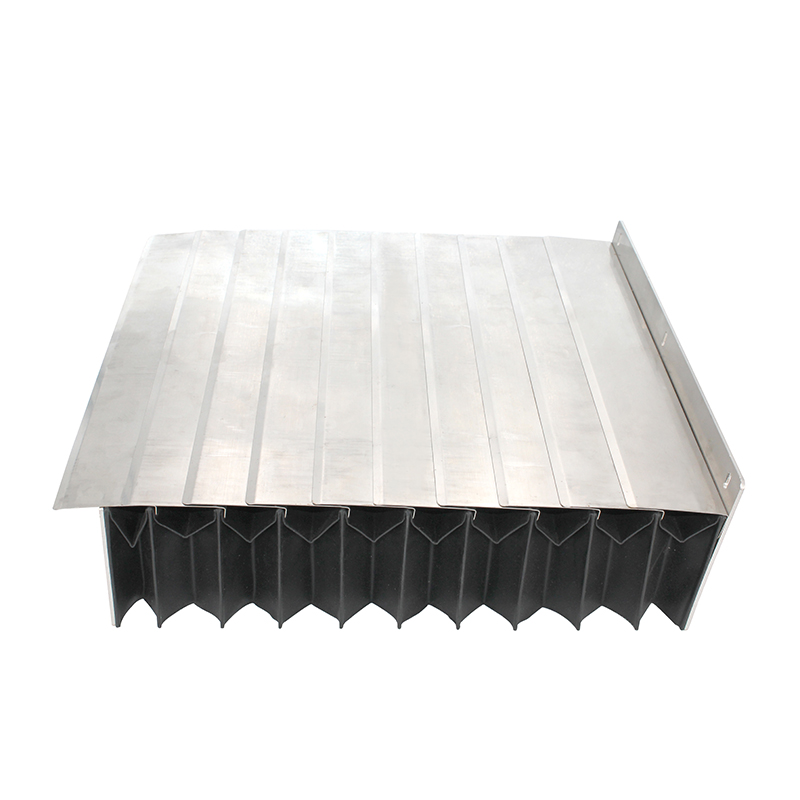

Metal chip conveyors come in various designs, each suited to different types of machining operations and materials. The most common types include

1. Drag Chain Conveyors These are robust systems that use chains to pull the metal chips along a defined path. Ideal for heavy-duty applications, drag chain conveyors can handle large amounts of thick and heavy chips.

2. Auger Conveyors With a helical screw mechanism, auger conveyors lift chips vertically and are particularly useful in operations where space constraints exist. These systems are efficient for transporting fine chips or small metal fragments.

3. Magnetic Conveyors Utilizing magnetic forces, these conveyors transport ferrous materials without them falling off. Magnetic conveyors are particularly effective for handling small, irregularly shaped chips.

4. Tubular Belt Conveyors This type involves a continuous belt enclosed in a tube, making it suitable for longer distances and various angles of elevation. It helps prevent chips from spilling and allows for gentle handling of the material.

Benefits of Metal Chip Conveyor Systems

Implementing a metal chip conveyor system brings numerous benefits to manufacturing operations

- Enhanced Efficiency Automated chip removal systems allow for uninterrupted machining processes, reducing machine downtime. Operators can focus on other tasks rather than manually cleaning up chips.

metal chip conveyor systems

- Improved Workplace Safety Accumulated metal chips can create tripping hazards and contribute to workplace injuries. A conveyor system helps maintain a cleaner and safer environment by efficiently removing debris.

- Increased Tool Life Removing chips from the machining area prevents re-cutting, which can dull tools and decrease their lifespan. This leads to cost savings by reducing the frequency of tool replacements.

- Optimized Recycling Many manufacturers are now focusing on sustainability, and a well-designed chip conveyor can facilitate recycling of metal scraps. By effectively transporting chips to recycling stations, companies can reduce waste and promote eco-friendliness.

- Cost Effectiveness Although the initial investment in a metal chip conveyor system can be significant, the long-term savings achieved through increased productivity and reduced labor costs justify the expense.

Considerations for Selection and Installation

When choosing a metal chip conveyor system, several factors should be taken into account

- Type of Material Different machines produce different types of chips (e.g., small, fine, large). Understanding the material characteristics helps in selecting an appropriate type of conveyor.

- Space and Layout The physical layout of the manufacturing facility can affect the type of conveyor that can be installed. Proper planning ensures that the conveyor works seamlessly within existing operations.

- Maintenance Requirements Conveyor systems require regular maintenance to operate efficiently. Consider choosing a system that offers easy access for maintenance and is durable enough to withstand operational demands.

- Integration with Existing Systems Ensuring that the new conveyor system can integrate well with existing machinery and operations is crucial for a smooth transition and optimal performance.

Conclusion

Metal chip conveyor systems are essential to modern metalworking and manufacturing processes. By enhancing efficiency, improving safety, and enabling better recycling practices, these systems play a vital role in elevating productivity standards in industrial settings. When selecting a metal chip conveyor, companies should carefully consider their specific needs, ensuring that they invest in a solution that delivers long-term benefits. As industries continue to evolve, the importance of efficient chip management will only grow, making these systems indispensable assets in the manufacturing landscape.