metal chip conveyor systems

Metal Chip Conveyor Systems Enhancing Efficiency in Manufacturing

In the manufacturing industry, managing metal chips and scrap is a critical aspect of maintaining efficiency and productivity. Metal chip conveyor systems have emerged as an essential solution for automating the removal of metal shavings, chips, and scrap from machining processes. These systems play a vital role in keeping manufacturing environments clean, safe, and organized, ultimately improving operational efficiency.

A metal chip conveyor system is designed to transport metallic waste created during machining operations, such as milling, turning, and grinding. The chips generated during these processes can be sharp, hazardous, and cumbersome, making it crucial to handle them effectively. By utilizing conveyor systems, manufacturers can automate the collection and transportation of these metal chips, freeing workers from repetitive and potentially hazardous manual labor.

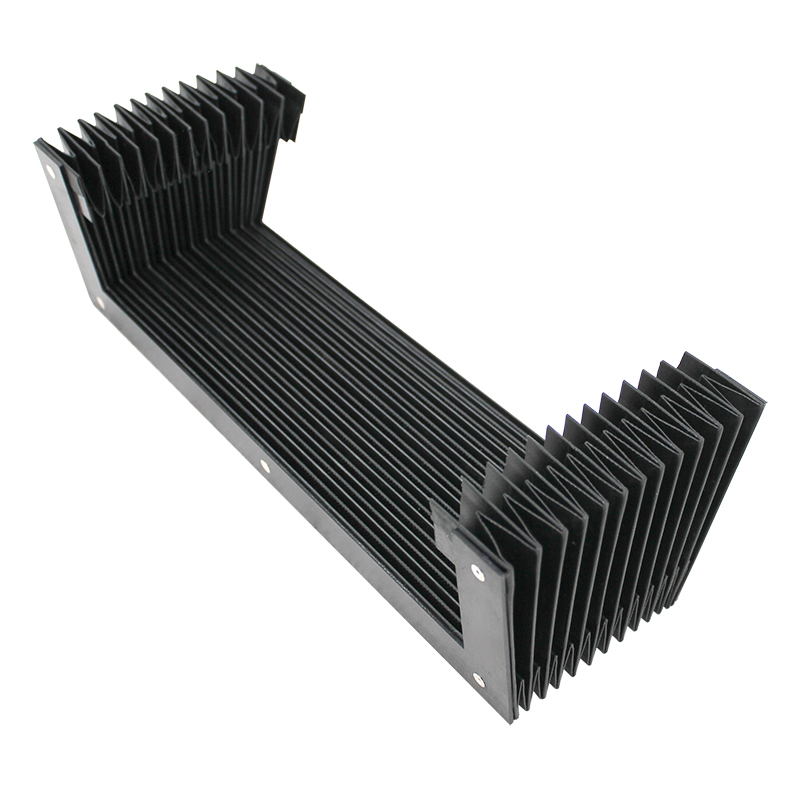

There are various types of metal chip conveyors, including belt conveyors, screw conveyors, and magnetic separators. Each type has its unique advantages tailored to specific manufacturing needs. For instance, belt conveyors are ideal for transporting large volumes of chips over extended distances, while screw conveyors can efficiently move chips in confined spaces. Magnetic separators are particularly effective for ferrous materials, ensuring that metal chips are captured and directed for recycling or disposal.

metal chip conveyor systems

Implementing metal chip conveyor systems not only enhances operational efficiency but also contributes to the overall cleanliness of the work environment. By minimizing the accumulation of metal chips on the factory floor, manufacturers can reduce the risk of accidents and improve safety for their employees. Additionally, a cleaner workspace can lead to better equipment maintenance and reduced downtime, further boosting productivity.

Moreover, many metal chip conveyor systems are designed with sustainability in mind. By facilitating the recycling of metal chips, these systems help manufacturers reduce waste and minimize their environmental footprint. Recycling metal not only conserves natural resources but also can result in significant cost savings for businesses.

In conclusion, metal chip conveyor systems represent a pivotal advancement in the manufacturing sector, addressing the challenges posed by metal waste management. By automating chip removal and enhancing workplace safety, these systems not only improve operational efficiency but also foster a culture of sustainability. As manufacturers continue to seek ways to optimize their processes, the adoption of metal chip conveyor systems will undoubtedly play a key role in shaping the future of efficient and responsible manufacturing practices.