Optimizing Metal Chip Conveyors for Efficient Manufacturing Processes and Waste Management Systems

Metal Chip Conveyor Systems Enhancing Efficiency in Manufacturing

In the manufacturing industry, efficiency and productivity are crucial for success. One often overlooked but essential component of this process is the metal chip conveyor system. These systems are designed to manage the removal and transport of metal chips, shavings, and scrap generated during machining operations. By integrating an effective metal chip conveyor, manufacturers can streamline operations, improve workplace safety, and reduce material waste.

Metal chips are a byproduct of various machining processes, such as milling, turning, and grinding. When not properly managed, these chips can accumulate and create safety hazards, impede workflow, and ultimately lead to costly downtimes. This is where metal chip conveyor systems come into play. They provide a reliable solution for the continuous removal of metallic waste, ensuring that production areas remain clean and organized.

metal chip conveyor systems

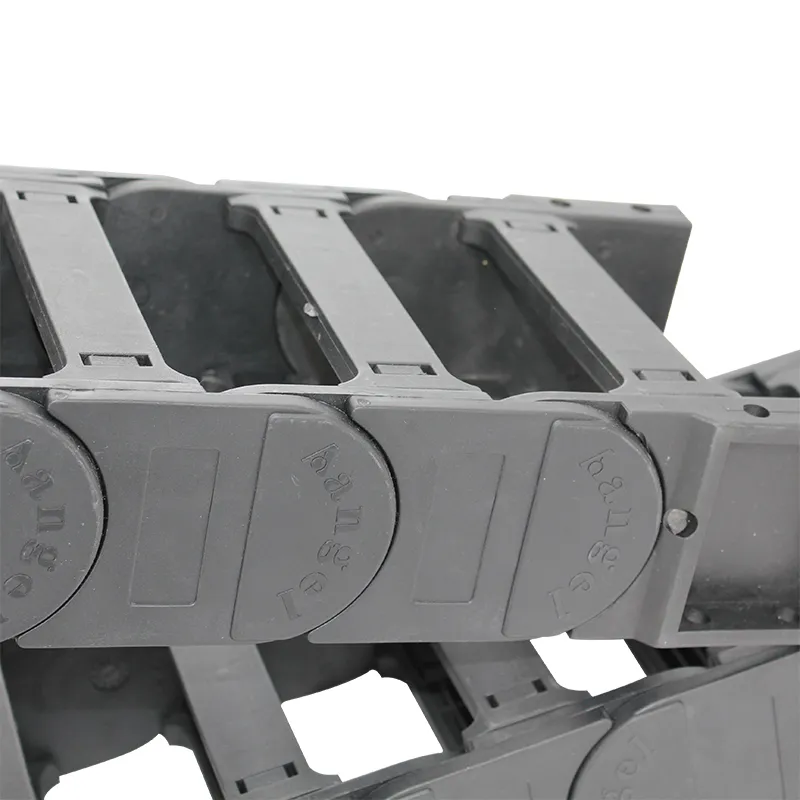

There are several types of metal chip conveyor systems, each designed to meet specific industry needs. The most common options include belt conveyors, screw conveyors, and magnetic conveyors. Belt conveyors are ideal for moving larger quantities of metal chips over longer distances, while screw conveyors are effective for transporting smaller, denser materials and are often used in tight spaces. Magnetic conveyors, on the other hand, are particularly beneficial for handling ferrous chips, as they can easily lift and transport them without any additional energy requirements.

Implementing an efficient metal chip conveyor system can significantly enhance operational efficiency. By automating the chip removal process, manufacturers can minimize manual handling and reduce the risk of injury to workers. This not only improves safety but also allows employees to focus on more critical tasks, ultimately boosting productivity. Moreover, with a well-designed conveyor system, companies can achieve better chip reclamation, leading to potential cost savings through recycling and repurposing materials.

In summary, metal chip conveyor systems play a pivotal role in modern manufacturing by enhancing efficiency, improving safety, and reducing waste. As industries continue to evolve, the importance of effective waste management solutions, such as these conveyor systems, will only grow. Investing in high-quality metal chip conveyor systems is essential for manufacturers looking to optimize their operations and maintain a competitive edge in an increasingly demanding market. With advancements in technology and an ever-growing push towards sustainability, these systems are not just an option; they are an integral part of a successful manufacturing strategy.