metal chip conveyor

The Essential Role of Metal Chip Conveyors in Modern Manufacturing

In the world of manufacturing, efficiency is key. Among the many systems that contribute to this efficiency, metal chip conveyors play a crucial role. These specialized conveyor systems are designed to handle the byproducts of metal machining processes, particularly the chips and scrap that are generated during operations like milling, turning, and drilling. The importance of metal chip conveyors cannot be overstated, as they not only streamline operations but also enhance workplace safety and environmental sustainability.

Understanding Metal Chip Conveyors

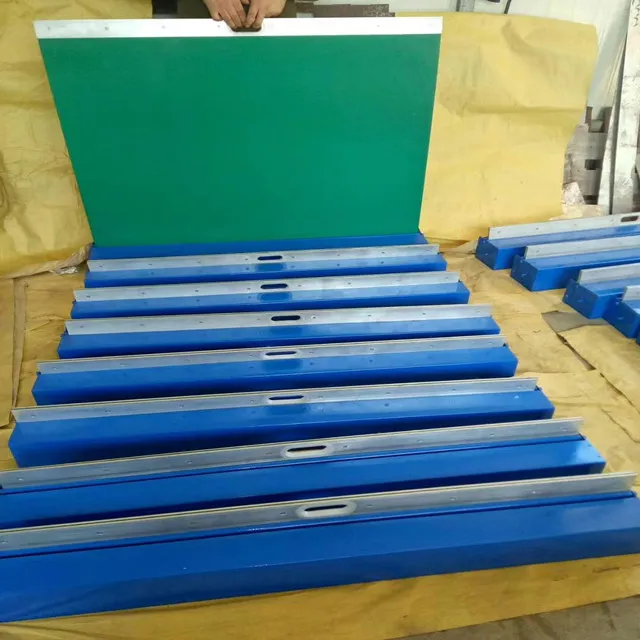

Metal chip conveyors are engineered to transport metal shavings, chips, and scrap materials away from machinery. These conveyors come in various designs, including hinged belt conveyors, screw conveyors, and magnetic conveyors, each tailored to handle specific types of metal waste. The choice of conveyor largely depends on the machining process, the type of metal being worked on, and the layout of the production facility.

For instance, hinged belt conveyors are robust and suitable for heavy chips, making them ideal for industries that deal with ferrous metals. Conversely, magnetic conveyors excel in removing small, thin chips and can easily transport them without the risk of falling off.

Enhancing Operational Efficiency

One of the primary benefits of metal chip conveyors is their ability to enhance operational efficiency. In traditional machining environments, manual removal of metal chips can lead to machine downtime and increased labor costs. Metal chip conveyors automate the process, allowing for continuous operation of machining equipment. This automation minimizes delays and optimizes production cycles, leading to increased output and a better return on investment.

Moreover, by keeping workspaces clean and organized, these conveyors help maintain a steady workflow. An uncluttered environment not only improves efficiency but also boosts employee morale. Workers can focus on their tasks without the added distraction of carpeted metal chips or the risk of slipping on the factory floor.

metal chip conveyor

Promoting Workplace Safety

In addition to operational benefits, metal chip conveyors significantly enhance workplace safety. Accumulation of metal chips can present numerous hazards, including slip and trip accidents, as well as potential damage to machinery. By efficiently transporting these chips away from work areas, conveyors reduce the risk of accidents, creating a safer environment for employees.

Additionally, metal chips can be sharp and pose a risk of injury. Conveyors ensure that these chips are properly handled and disposed of, further contributing to a safer workplace. Many modern conveyor systems are also equipped with protective features, such as guards and safety switches, to prevent accidents during operation.

Environmental Considerations

Sustainability is a growing concern across all industries, and metal chip conveyors play a vital role in promoting environmental responsibility. These systems facilitate the efficient collection and recycling of metal scrap. By transporting the metal chips to designated recycling areas, manufacturers can reduce waste and minimize their environmental footprint.

Recycling metal chips not only conserves resources but also lowers the costs associated with purchasing raw materials. This practice aligns with the principles of the circular economy, where materials are reused and repurposed rather than discarded.

Conclusion

In summary, metal chip conveyors are an indispensable component in modern manufacturing environments. By enhancing operational efficiency, promoting workplace safety, and supporting environmental sustainability, these systems play a vital role in the overall productivity and effectiveness of manufacturing processes. As industries continue to evolve, the importance of efficient waste management and process optimization will only grow, positioning metal chip conveyors as essential tools for future success in manufacturing. Their ability to automate chip removal, coupled with the safety and environmental benefits they provide, makes them a key element in the quest for more efficient and responsible manufacturing practices.