Enhanced Solutions for Efficient Metal Chip Handling and Conveyor Systems

Understanding Metal Chip Conveyors Essential Tools for Manufacturing

In modern manufacturing environments, efficiency and cleanliness are paramount. One of the tools that has significantly contributed to these goals is the metal chip conveyor. These specialized systems are designed to transport metal shavings, chips, and waste produced during machining processes, ensuring that production lines remain organized and functional.

The Importance of Metal Chip Conveyors

Every machining operation, whether it involves milling, turning, or grinding, generates metal debris. If not managed properly, these chips can accumulate, leading to several problems, including machine malfunction, safety hazards, and decreased productivity. Metal chip conveyors play a vital role in mitigating these issues by facilitating the efficient removal of metal waste from the workstation.

By effectively transporting chips away from machines, metal chip conveyors help to maintain a clean and safe working environment. This, in turn, reduces the risk of accidents caused by slipping on debris or injuries from sharp chips. Additionally, a clean workspace aids in enhancing machine longevity, as the likelihood of overheating and wear caused by chip buildup is diminished.

Types of Metal Chip Conveyors

There are several types of metal chip conveyors available on the market, each designed to meet specific needs and applications

1. Drag Chain Conveyors These are among the most commonly used chip conveyors. They consist of a series of chain links that drag the metal chips along a trough. Drag chain conveyors are suitable for handling heavy loads and can work with both dry and wet chips.

2. Screw Conveyors Also known as auger conveyors, these systems use a rotating screw to move chips along a pipe or trough. They are particularly effective for transporting small, fine chips and can be inclined or horizontal, depending on the layout requirements.

3. Magnetic Conveyors When dealing with ferrous metal chips, magnetic conveyors can be incredibly effective. These systems use powerful magnets to pull metal debris along a conveyor bed, keeping it securely in place while reducing the risk of spillage.

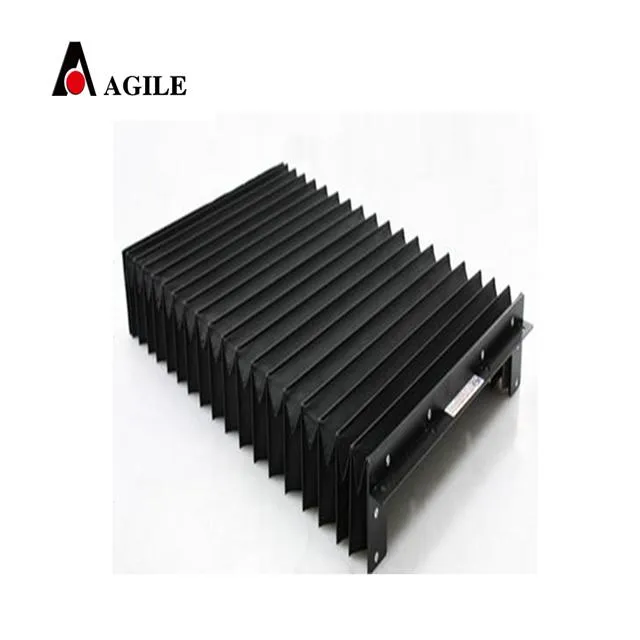

metal chip conveyor

4. Vibratory Conveyors Utilizing vibrations to move material along a surface, vibratory conveyors are often used for lighter chips. They can be adjusted to control the speed and movement, making them versatile for various applications.

Advantages of Implementing Metal Chip Conveyors

Integrating metal chip conveyors into a manufacturing workflow offers numerous advantages

- Improved Efficiency By automating the chip removal process, manufacturers can save time and labor costs. Operators can focus on production rather than manual cleanup, allowing for increased output.

- Enhanced Machine Performance Keeping machines clear of excessive chips reduces wear and tear, resulting in more reliable performance and less downtime due to maintenance.

- Waste Management Metal chips can be recycled; therefore, by using a conveyor system, manufacturers can optimize their waste management processes, enhancing sustainability efforts.

- Safety Improvements With a clean workspace and reduced risks associated with chip accumulation, overall workplace safety is enhanced.

Conclusion

In conclusion, metal chip conveyors are a crucial element in the contemporary manufacturing landscape. They streamline operations by efficiently managing the by-products of machining processes, ultimately leading to safer environments, improved productivity, and enhanced machine longevity. Whether it’s through drag chain, screw, magnetic, or vibratory systems, these conveyors help to maintain order in the workplace, paving the way for more efficient manufacturing practices. As industries continue to evolve, the importance of such systems will likely grow, highlighting their role in creating safer, cleaner, and more productive manufacturing environments. Investing in the right type of metal chip conveyor can yield significant benefits, ensuring that manufacturers stay competitive in an increasingly challenging market.