Durable Metal Cable Drag Chain for Efficient Cable Management and Organization

Exploring Metal Cable Drag Chains An Essential Component for Industrial Applications

In modern industrial environments, efficient management of cables and hoses is vital for the smooth operation of machinery and equipment. One of the most effective solutions for this purpose is the metal cable drag chain, a versatile and robust component designed to protect and guide cables during movement. With its distinct advantages, metal cable drag chains have become an essential part of various applications in manufacturing, automotive, robotics, and many other sectors.

What Is a Metal Cable Drag Chain?

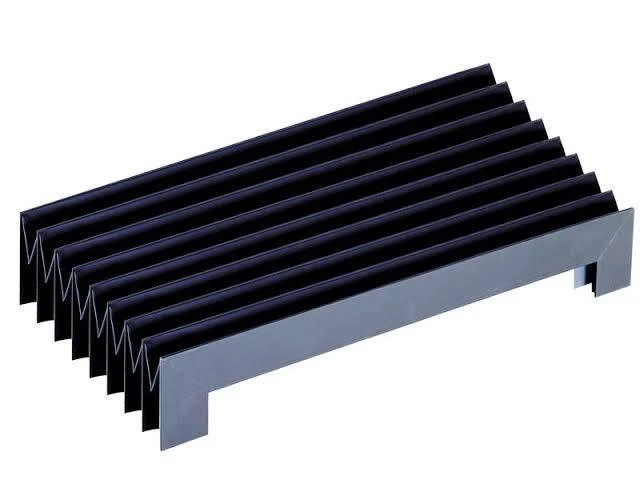

A metal cable drag chain, also known as a cable carrier or energy chain, is a modular component that provides a controlled and organized path for cables and hoses. Unlike traditional wiring methods that expose cables to potential damage, drag chains enclose them within a protective casing, thereby minimizing wear and tear. These drag chains consist of interconnected links that can bend and flex, allowing them to navigate complex pathways and movements of machinery.

Key Advantages of Metal Cable Drag Chains

1. Durability and Strength Metal drag chains are typically constructed from high-quality materials such as stainless steel or aluminum. This ensures they can withstand harsh operating conditions, heavy loads, and extreme temperatures. Their robust design makes them suitable for both indoor and outdoor applications, where environmental factors can significantly impact equipment performance.

2. Protection of Cables and Hoses The primary function of a drag chain is to safeguard cables from mechanical damage, abrasion, and entanglement. By providing a structured pathway, these chains prevent wear on cables and hoses, extending their service life and reducing maintenance costs.

3. Flexibility in Design Metal cable drag chains are available in various sizes, shapes, and configurations. This flexibility allows for customization to meet specific application requirements. Whether it's for vertical lifts, horizontal movements, or even multi-axis applications, there is a drag chain design that fits.

metal cable drag chain

4. Ease of Installation and Maintenance Most metal drag chains are designed for easy installation, with features that allow for straightforward assembly and disassembly. This simplicity reduces downtime during maintenance or upgrades, making them a practical choice for busy industrial settings.

5. Reduced Noise Levels In environments where noise reduction is crucial, metal drag chains can help minimize operational noise. The enclosed design absorbs vibrations that would otherwise contribute to noise, promoting a quieter workplace.

Applications of Metal Cable Drag Chains

The versatility of metal cable drag chains makes them suitable for a wide range of industries. In robotics, they are used to guide power and control cables within robotic arms, ensuring seamless movement. In manufacturing, they are found in automated production lines, where they manage the electrical and pneumatic lines necessary for machinery operation. Additionally, in the automotive industry, they provide cable management solutions in assembly plants and testing facilities.

Choosing the Right Metal Cable Drag Chain

When selecting a metal cable drag chain for your application, several factors should be considered. These include the weight of the cables or hoses to be carried, the required bend radius, operating environment, and the frequency of movement. Consulting with a manufacturer or specialist can help ensure that the right drag chain is chosen, optimizing performance and safety.

Conclusion

Metal cable drag chains play an indispensable role in enhancing the efficiency and safety of industrial operations. Their durability, flexibility, and protective features make them a fundamental component in cable management systems. As industries continue to evolve and demand higher operational standards, the use of metal cable drag chains will undoubtedly become even more prevalent, fostering innovation and advancement across various sectors. Investing in quality drag chains is an investment in the longevity and reliability of industrial equipment.