metal bellow cover

The Role and Importance of Metal Bellow Covers

In the world of engineering, particularly in areas involving machinery and automation, the use of protective components is crucial. One such component that often goes unnoticed yet plays a vital role is the metal bellow cover. These covers serve not only to protect sensitive machinery parts from environmental factors but also to enhance operational efficiency and longevity.

Understanding Metal Bellow Covers

Metal bellow covers are flexible protective housings made from thin metal sheets that can expand and contract. They are designed to shield moving parts of machinery from dust, dirt, debris, and moisture. Commonly used in applications involving rods, spindles, and other linear motion equipment, metal bellow covers can prevent contaminants from causing wear and tear, thereby increasing the lifespan of vital machine components.

The basic structure of a metal bellow involves a series of folds or convolutions that allow for significant axial movement. This flexibility not only enables the shaft or rod to perform its functions without restriction but also ensures that the cover remains intact and protective, regardless of the complex dynamics at play.

Applications in Various Industries

Metal bellow covers find applications across several industries, including manufacturing, robotics, aerospace, and automotive. In manufacturing, they are used to protect linear guides and ball screws in CNC (computer numerical control) machines. Without these protective covers, even a small particle of dust could lead to catastrophic failures or expensive downtime.

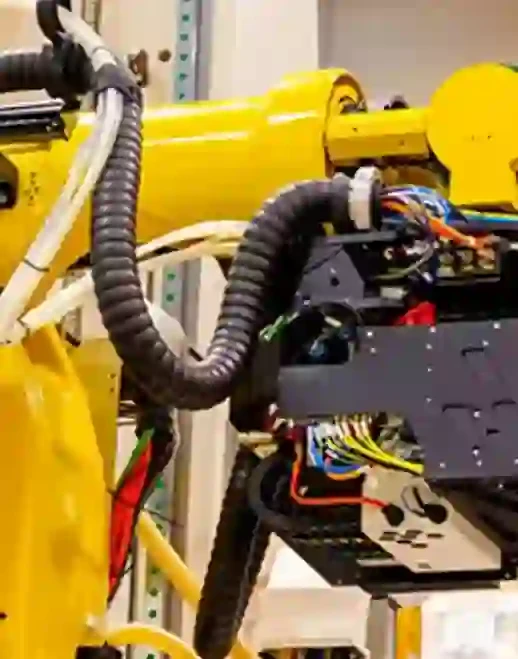

In the robotics sector, where precision and cleanliness are paramount, metal bellow covers safeguard sensitive components from environmental hazards while allowing for the requisite range of motion. Similarly, in aerospace applications, these covers are essential to protect landing gear and other moving parts from the adverse effects of harsh weather conditions and foreign object debris.

metal bellow cover

Benefits of Metal Bellow Covers

1. Protection Against Contaminants The primary advantage of using metal bellow covers is their ability to protect critical components from contaminants, such as dust, oils, and moisture. This protection is key in maintaining smooth operation and reducing wear.

2. Durability Metal bellow covers are typically made from materials like stainless steel or other alloys that are resistant to corrosion and wear. This durability ensures they can withstand harsh operating conditions, which is particularly important in heavy-duty applications.

3. Flexibility The unique design of metal bellows allows for significant movement, accommodating various types of machinery without hindering operation. This flexibility is crucial in dynamic systems where components may be subject to significant displacement.

4. Cost-Effectiveness By protecting vital components, metal bellow covers drastically reduce maintenance costs and increase the lifespan of machinery. Organizations can save on repairs and replacements in the long run.

5. Enhanced Aesthetic Appeal In many cases, metal bellow covers can also improve the visual appeal of machinery, giving them a polished look that enhances overall brand perception in industries where equipment aesthetics matter.

Conclusion

In conclusion, metal bellow covers are an indispensable part of modern machinery design. Their role in protecting against contaminants while accommodating motion makes them an ideal solution for various industrial applications. As industries continue to push the boundaries of technology and efficiency, the importance of such protective components will only grow. Investing in quality metal bellow covers not only fortifies the machinery but also ensures operational excellence and longevity, making them a wise choice for any engineering application.