metal bellow cover

The Importance of Metal Bellow Covers in Industrial Applications

In various industrial applications, the need for durability and flexibility in hardware components is paramount. One such component that plays a crucial role in protecting sensitive machinery parts is the metal bellow cover. These covers serve as vital protective barriers, ensuring the longevity and efficient performance of equipment exposed to harsh operational environments.

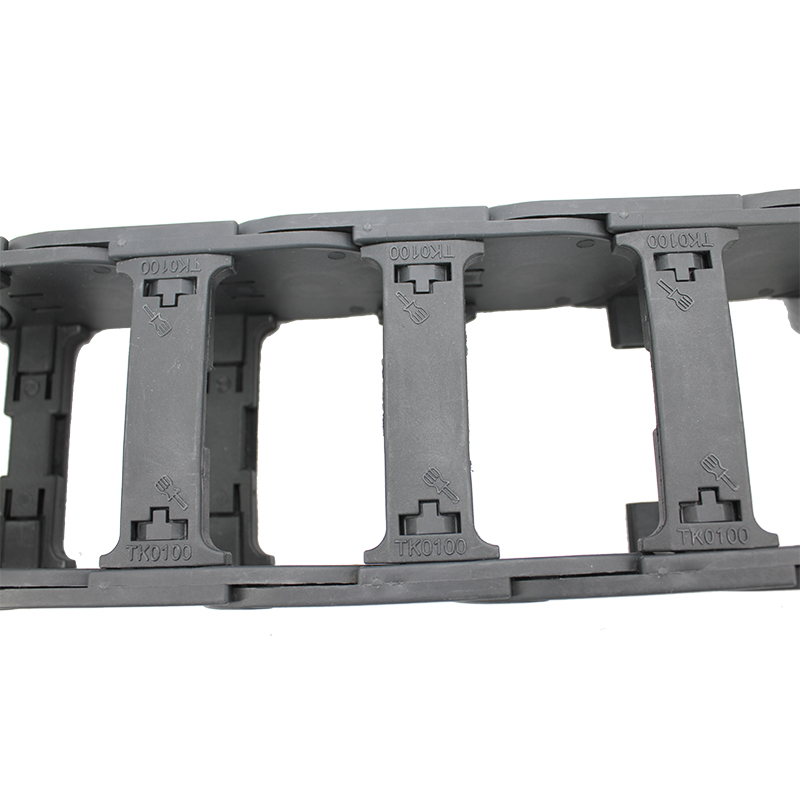

What are Metal Bellow Covers?

Metal bellow covers are flexible protective devices made from metal, typically stainless steel or other alloys, designed to shield machinery components from dust, debris, moisture, and other environmental deteriorators. The bellow structure allows for movement, accommodating the dynamic motions of machinery while maintaining a seal that prevents contaminants from infiltrating sensitive parts.

Key Features and Benefits

1. Protection from Contaminants One of the primary functions of metal bellow covers is to protect moving parts from environmental contaminants. In industries such as manufacturing, aerospace, and automotive, equipment is often exposed to dust, dirt, and other debris that can cause wear and tear. The bellow cover acts as a shield, keeping these harmful substances at bay.

2. Flexibility and Adaptability The design of bellow covers allows them to expand and contract with mechanical movement. This flexibility is essential for applications where components are subjected to dynamic motion. Unlike rigid covers, metal bellows can accommodate various ranges of motion without compromising their protective capabilities.

3. Durability Metal bellows are known for their robust construction, which makes them highly durable and resistant to wear. They can withstand extreme temperatures and harsh chemicals, which are common in many industrial settings. This durability translates into a longer lifespan for both the bellow cover and the machinery it protects.

metal bellow cover

4. Customizable Designs Metal bellow covers can be customized to meet specific dimensional and operational requirements. Manufacturers can tailor the size, shape, and material of the bellow covers based on the unique needs of each application. This customizability ensures optimal performance and protection.

5. Cost-Effectiveness Although there is an initial investment associated with metal bellow covers, their ability to prolong the life of machinery can lead to significant cost savings in the long run. Reducing the frequency of repairs and replacements contributes to a lower overall cost of maintenance.

Applications of Metal Bellow Covers

Metal bellow covers are extensively used in various industries, including

- Machinery and Equipment Protecting linear guides, ball screws, and other moving components. - Automotive Shielding critical parts in engines and transmissions from contaminants. - Aerospace Safeguarding sensitive instruments and machinery from environmental factors. - Robotics Ensuring that joints and actuators remain clean and functional.

Conclusion

In conclusion, metal bellow covers are essential components in many industrial applications, providing protection, flexibility, and durability. Their ability to withstand challenging environments while adapting to movement makes them an invaluable asset for maintaining operational efficiency and ensuring the longevity of machinery. Investing in high-quality metal bellow covers can lead to enhanced performance and significant cost savings for businesses in diverse sectors. As industries continue to evolve, the importance of such protective solutions remains undisputed.