magnetic chip conveyor manufacturer

The Role of Magnetic Chip Conveyors in Modern Manufacturing

In the realm of modern manufacturing, efficiency and precision are paramount. One innovative solution that has gained significant attention is the magnetic chip conveyor. These specialized conveyors are designed to handle metal chips, swarf, and other debris generated during machining processes. As industries continue to evolve and seek better methods for waste management and material handling, magnetic chip conveyors play a critical role in enhancing productivity and operational efficiency.

Understanding Magnetic Chip Conveyors

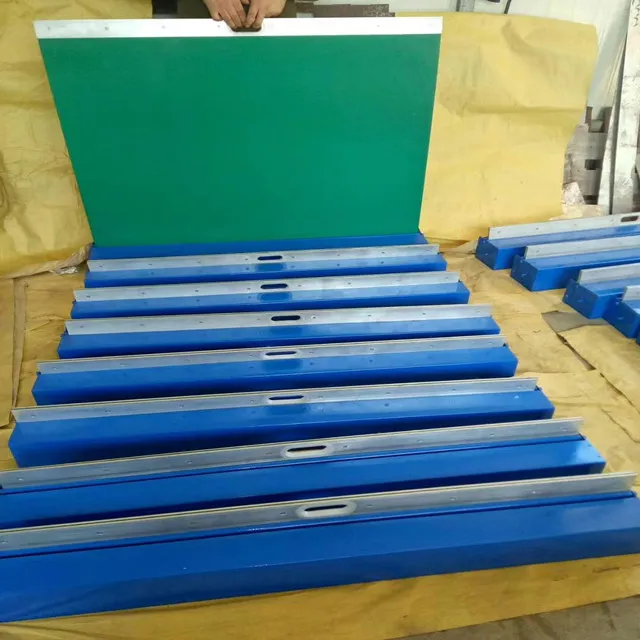

Magnetic chip conveyors are mechanical systems that utilize magnetic force to transport ferrous metal chips from one location to another. Unlike traditional conveyor systems, which may use belts or rollers, magnetic conveyors leverage powerful magnets to securely hold and move metal materials. This allows for a more efficient and effective means of collecting waste, improving cleanup time, and minimizing the risk of cross-contamination during the machining process.

There are various types of magnetic chip conveyors available, including flat plate designs, magnetic filtration systems, and custom-built solutions tailored to specific manufacturing requirements. Each type serves a unique function, from simple transport to sophisticated filtration of metal particles and machinist debris.

Advantages of Using Magnetic Chip Conveyors

1. Enhanced Efficiency Magnetic chip conveyors facilitate a continuous flow of material, reducing downtime during the manufacturing process. With automated chip handling systems, manufacturers can keep their machines running smoothly, allowing for increased throughput and productivity.

2. Reduced Labor Costs By automating chip removal, companies can significantly cut labor costs associated with manual cleanup and handling. Employees can redirect their focus to more critical tasks, enhancing overall shop floor efficiency.

3. Improved Safety The presence of metal chips and swarf on the shop floor can pose safety hazards, including slip-and-fall accidents. Magnetic chip conveyors help maintain a cleaner workspace, reducing potential risks to employees.

magnetic chip conveyor manufacturer

4. Versatility Magnetic chip conveyors can handle various shapes and sizes of metal debris, making them suitable for diverse manufacturing operations—from CNC machining to injection molding. Their adaptability allows businesses to implement a single solution for multiple machines and processes.

5. Environmental Considerations Efficient chip removal is not just a matter of convenience; it also supports environmentally sustainable practices. By reducing waste and promoting recycling of metal chips, manufacturers can contribute to a greener production process.

Choosing the Right Manufacturer

When selecting a magnetic chip conveyor manufacturer, several factors should be considered to ensure you are making a sound investment. Experience and expertise in the field are essential; a manufacturer with a proven track record will be more equipped to understand your specific needs and provide tailored solutions.

Customizability is another important aspect. A reputable manufacturer will offer various configurations and features to suit your particular application, whether that involves handling large volumes of chips or implementing advanced filtration systems. Additionally, inquire about the materials used in the construction of the conveyor; quality components will lead to longer-lasting performance and reduced maintenance costs.

Finally, consider customer support and service. The best manufacturers will not only provide a reliable product but also offer ongoing assistance, ensuring that your system operates at peak performance over time.

Conclusion

In conclusion, magnetic chip conveyors are an integral part of modern manufacturing, offering significant advantages in terms of efficiency, cost savings, and safety. By automating the removal of metal debris, manufacturers can streamline their operations, reduce labor expenses, and contribute to a safer workplace. Choosing the right manufacturer is crucial to reaping these benefits, so businesses should invest time in researching reputable suppliers that align with their needs. As industries continue to transform, the role of magnetic chip conveyors in optimizing production processes will undoubtedly grow, paving the way for a more efficient and sustainable manufacturing future.