Innovative Magnetic Chip Conveyor Solutions for Efficient Metalworking Operations

The Advancements and Applications of Magnetic Chip Conveyors

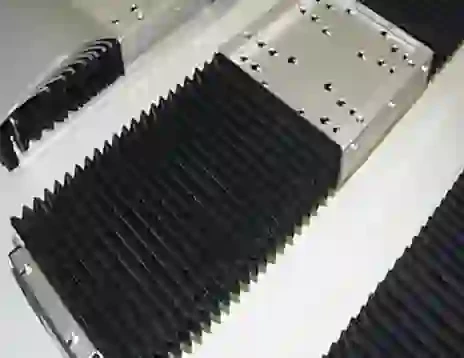

In modern manufacturing environments, efficient material handling systems are critical to enhancing productivity and ensuring a streamlined workflow. One of the most innovative solutions in this area is the magnetic chip conveyor. Designed specifically to manage metal chips and shavings generated during machining processes, these conveyors have transformed how industries deal with waste management and recycling.

What is a Magnetic Chip Conveyor?

A magnetic chip conveyor is a specialized type of conveyor system that uses magnetic forces to transport ferrous materials, such as metal chips and shavings, away from machining areas. These conveyors operate on the principle of magnetism, utilizing either permanent magnets or electromagnets to securely hold and transport metal debris. Unlike traditional belt conveyors, magnetic chip conveyors minimize the risk of material spillage and improve overall handling efficiency.

Key Features and Benefits

1. Efficient Material Handling Magnetic chip conveyors are specifically designed to handle the heavy and often abrasive nature of metal chips. They can carry large volumes of material without the risks of clogging or breakdowns that are common with other conveyor types.

2. Reduce Contamination By effectively transporting metal scraps from the machining area, magnetic chip conveyors help in maintaining a clean working environment. This not only reduces the risk of contamination in the production process but also enhances workplace safety.

3. Customizable Design These conveyors can be customized to fit various production layouts and machinery setups. With options for inclined transport, automated control systems, and integration with existing equipment, magnetic chip conveyors can be tailored to meet specific operational needs.

4. Durability and Low Maintenance Constructed from robust materials and featuring minimal moving parts, magnetic chip conveyors are built to withstand the harsh conditions of manufacturing environments. This durability results in lower maintenance costs and reduced downtime, ultimately leading to higher productivity.

magnetic chip conveyor

5. Eco-Friendly Solution By facilitating the efficient collection and transport of metal chips for recycling, magnetic chip conveyors contribute to sustainable manufacturing practices. This not only aids in waste management but also helps companies meet environmental regulations.

Applications Across Industries

Magnetic chip conveyors are widely used in various industries where metalworking processes are prevalent. They find applications in

- Automotive Manufacturing In automotive factories, where precision machining of various components generates significant metal waste, magnetic chip conveyors are vital to transporting chips efficiently, thus enhancing overall workshop productivity.

- Aerospace Industry The aerospace sector requires high tolerances and precision machining, leading to the production of fine metal shards. Magnetic chip conveyors ensure that these chips are collected and managed effectively, minimizing downtime.

- Metalworking Shops Small to medium-sized metalworking operations benefit immensely from magnetic chip conveyors, allowing them to maintain an organized workspace while efficiently recycling metals.

- Tool and Die Manufacturing In tool and die shops, the need for clean and accurate mass production makes magnetic chip conveyors particularly advantageous. They help in keeping operations smooth and focused on productivity rather than waste management.

Conclusion

Magnetic chip conveyors represent a significant advancement in the field of material handling. By leveraging the principles of magnetism, they offer an effective solution for transporting metal scraps, thereby enhancing productivity, reducing contamination, and contributing to a safer working environment. As industries continue to seek innovative ways to improve efficiency and sustainability, the importance of magnetic chip conveyors will only grow, solidifying their place as an essential component in modern manufacturing ecosystems. Investing in these systems not only streamlines operations but also aligns with broader environmental goals, making them a wise choice for forward-thinking enterprises.