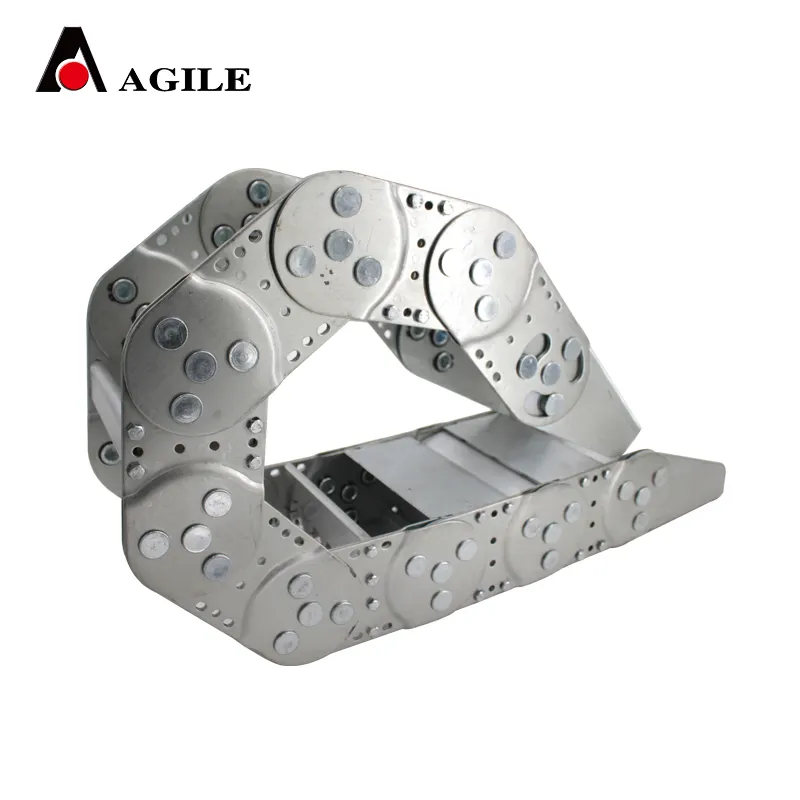

magnetic chip conveyor

Magnetic Chip Conveyor Enhancing Efficiency in Metalworking Industries

In the fast-paced world of manufacturing, particularly in the metalworking sector, efficiency and productivity are paramount. One critical component that contributes to these factors is the magnetic chip conveyor. This innovative device is designed to handle and transport metal shavings, chips, and debris generated during machining processes, thus ensuring a cleaner and more efficient working environment.

The primary function of a magnetic chip conveyor is to collect ferrous materials from production areas. Unlike traditional conveyors that may require manual cleanup, the magnetic chip conveyor utilizes powerful magnets to attract and hold metallic chips, effectively removing them from the machining area. This not only minimizes downtime associated with manual cleaning but also enhances worker safety by reducing slip hazards created by scattered debris.

One of the significant advantages of magnetic chip conveyors is their adaptability to various types of machines. Whether used with lathes, milling machines, or grinders, these conveyors can be tailored to meet specific needs. They come in various configurations, including flat and inclined designs, making it easy to integrate them into existing production lines. Moreover, many models are equipped with features such as adjustable heights and speeds, allowing operators to optimize the system according to their operational requirements.

magnetic chip conveyor

In addition to improving workplace efficiency, magnetic chip conveyors contribute to cost savings. By facilitating the easy collection of metal chips, these systems enable companies to recycle and reuse materials, thereby reducing waste and lowering material costs. Furthermore, keeping the workspace clean helps prolong the life of machines by preventing dust and debris buildup, ultimately minimizing maintenance costs and extending equipment lifespan.

The integration of technology has further enhanced the capabilities of magnetic chip conveyors. Many modern systems feature automated controls, allowing for seamless operation and real-time monitoring of chip removal processes. This automation not only simplifies operations but also provides valuable data that can be analyzed for continuous improvement in manufacturing processes.

Environmental concerns also drive the adoption of magnetic chip conveyors. As industries strive to become more sustainable, reducing waste and increasing recycling rates is crucial. By using magnetic conveyors to efficiently collect ferrous scrap, manufacturers can contribute to a greener planet while also benefiting from the economic advantages of recycling their materials.

In conclusion, the magnetic chip conveyor serves as an essential tool in the metalworking industry, playing a vital role in enhancing efficiency, ensuring worker safety, and promoting sustainable practices. As manufacturing processes continue to evolve, the importance of innovative solutions like magnetic chip conveyors will only grow, making them a worthwhile investment for companies aiming to stay competitive in the ever-changing landscape of manufacturing.