cnc machine used metal swarf chip conveyor

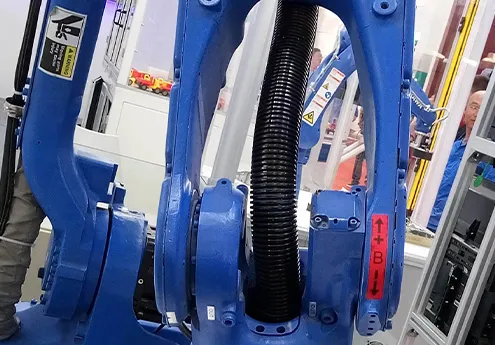

Navigating the intricate world of industrial manufacturing, one quickly appreciates the astounding role of machine tool chip conveyors. These devices, while sometimes overlooked, play a pivotal role in ensuring operational efficiency by managing and disposing of metal chips that are produced during machining processes.

Professional expertise in setting up and maintaining these conveyors cannot be understated. Improper installation can lead to inefficiencies, potential downtimes, or worse, damage to other expensive equipment. Manufacturers often provide training sessions and comprehensive guides to facilitate the correct operation of chip conveyors. Furthermore, industry experts recommend regular maintenance checks to ensure that all components, such as motors and bearings, are functioning optimally. The authority of machine tool chip conveyors extends to their environmental impact, as they contribute to cleaner and more sustainable manufacturing processes. By efficiently managing waste, they not only help in minimizing clutter in the workspace but also enhance the recycling process of metal chips. The extracted material can often be reprocessed, reducing the demand for raw resources and promoting circular economic practices. For those seeking to invest in machine tool chip conveyors, trustworthiness is a crucial factor when selecting suppliers. It is paramount to engage with established manufacturers known for their quality and customer service. Quality certifications, customer testimonials, and case studies of successful implementations can significantly aid decision-making processes. These factors not only guarantee peace of mind but also assure long-term benefits, enhancing trust and solidifying the business partnership. The strategic implementation of machine tool chip conveyors brings a measurable increase in productivity and a decrease in waste, forming the backbone of efficient manufacturing. Their role, often underappreciated, is critical in ushering industries towards heightened performance and scalability. Indeed, those who endeavor to optimize their manufacturing techniques by integrating such precision tools are laying down strong foundations for future growth and sustainability.

Professional expertise in setting up and maintaining these conveyors cannot be understated. Improper installation can lead to inefficiencies, potential downtimes, or worse, damage to other expensive equipment. Manufacturers often provide training sessions and comprehensive guides to facilitate the correct operation of chip conveyors. Furthermore, industry experts recommend regular maintenance checks to ensure that all components, such as motors and bearings, are functioning optimally. The authority of machine tool chip conveyors extends to their environmental impact, as they contribute to cleaner and more sustainable manufacturing processes. By efficiently managing waste, they not only help in minimizing clutter in the workspace but also enhance the recycling process of metal chips. The extracted material can often be reprocessed, reducing the demand for raw resources and promoting circular economic practices. For those seeking to invest in machine tool chip conveyors, trustworthiness is a crucial factor when selecting suppliers. It is paramount to engage with established manufacturers known for their quality and customer service. Quality certifications, customer testimonials, and case studies of successful implementations can significantly aid decision-making processes. These factors not only guarantee peace of mind but also assure long-term benefits, enhancing trust and solidifying the business partnership. The strategic implementation of machine tool chip conveyors brings a measurable increase in productivity and a decrease in waste, forming the backbone of efficient manufacturing. Their role, often underappreciated, is critical in ushering industries towards heightened performance and scalability. Indeed, those who endeavor to optimize their manufacturing techniques by integrating such precision tools are laying down strong foundations for future growth and sustainability.