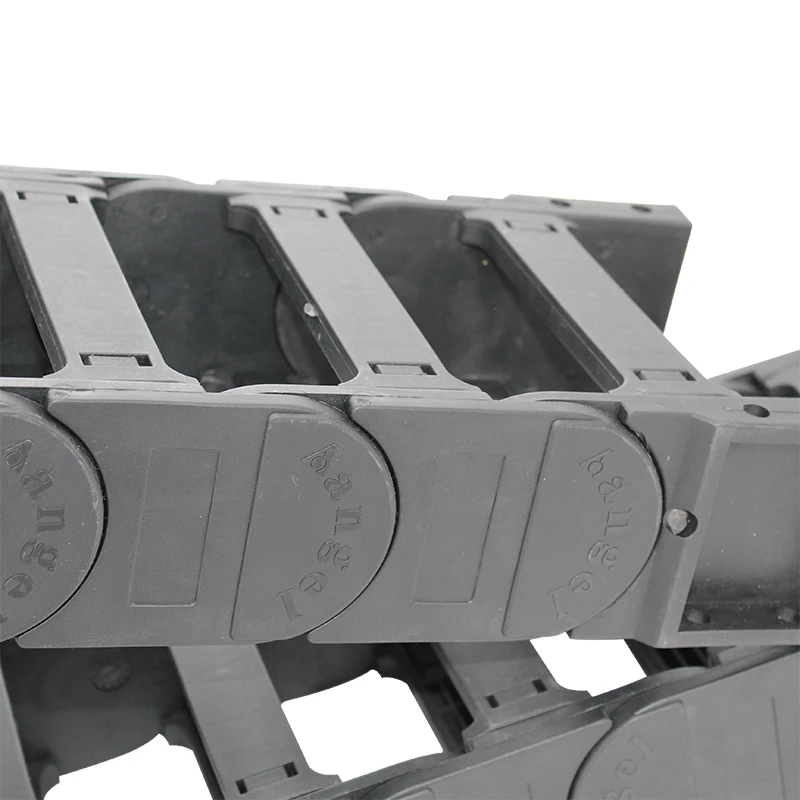

machine chip conveyor

Machine chip conveyors are essential components in numerous industrial settings, offering reliable solutions for handling metal scrap efficiently. At the intersection of machine tooling and waste management, these conveyors symbolize a critical innovation that supports seamless production processes while ensuring workplace safety and operational efficiency.

Scraper-type conveyors bring versatility, handling both wet and dry machining environments effortlessly. Their simple yet effective design removes debris from coolant tanks, preventing clogs and maintaining the efficiency of the machining process. The scraper-type model is particularly favored for its ability to deal with smaller chips and sludge, often a challenge for other conveyor types. In practice, selecting the appropriate machine chip conveyor requires a detailed analysis of the production setup and waste characteristics. Experts in the field evaluate factors such as chip size, production volume, coolant flow, and space constraints to recommend systems that offer optimal performance. Employing these conveyors effectively demands not only selecting the right type but also ensuring proper integration into existing systems to maximize throughput and minimize waste handling times. The authority of leading manufacturers in chip conveyor technology stems from decades of expertise and innovation. Companies like Hennig, Mayfran, and LNS ChipBLASTER leverage cutting-edge engineering to develop products that address contemporary challenges in machining environments. Their state-of-the-art designs reflect a deep understanding of industry needs, providing businesses with reliable, long-lasting solutions that enhance productivity and sustainability. Trust is further built through transparent communication and after-sales support, where manufacturers guide clients in installation, maintenance, and troubleshooting. Comprehensive training programs further ensure operators are well-versed in utilizing these systems effectively, ensuring smooth operations and extending the lifespan of the equipment. In conclusion, machine chip conveyors represent a pivotal advancement in industrial waste management within machining sectors. Their ability to enhance productivity, safety, and operational cost-efficiency marks them as invaluable assets in modern manufacturing. Companies investing in high-quality conveyors not only optimize their operational workflow but also affirm their commitment to sustainable and efficient production practices. As industries evolve, the continuous enhancement and integration of such technologies will remain paramount, underscoring the importance of expertise and innovation in the realm of machine waste handling.

Scraper-type conveyors bring versatility, handling both wet and dry machining environments effortlessly. Their simple yet effective design removes debris from coolant tanks, preventing clogs and maintaining the efficiency of the machining process. The scraper-type model is particularly favored for its ability to deal with smaller chips and sludge, often a challenge for other conveyor types. In practice, selecting the appropriate machine chip conveyor requires a detailed analysis of the production setup and waste characteristics. Experts in the field evaluate factors such as chip size, production volume, coolant flow, and space constraints to recommend systems that offer optimal performance. Employing these conveyors effectively demands not only selecting the right type but also ensuring proper integration into existing systems to maximize throughput and minimize waste handling times. The authority of leading manufacturers in chip conveyor technology stems from decades of expertise and innovation. Companies like Hennig, Mayfran, and LNS ChipBLASTER leverage cutting-edge engineering to develop products that address contemporary challenges in machining environments. Their state-of-the-art designs reflect a deep understanding of industry needs, providing businesses with reliable, long-lasting solutions that enhance productivity and sustainability. Trust is further built through transparent communication and after-sales support, where manufacturers guide clients in installation, maintenance, and troubleshooting. Comprehensive training programs further ensure operators are well-versed in utilizing these systems effectively, ensuring smooth operations and extending the lifespan of the equipment. In conclusion, machine chip conveyors represent a pivotal advancement in industrial waste management within machining sectors. Their ability to enhance productivity, safety, and operational cost-efficiency marks them as invaluable assets in modern manufacturing. Companies investing in high-quality conveyors not only optimize their operational workflow but also affirm their commitment to sustainable and efficient production practices. As industries evolve, the continuous enhancement and integration of such technologies will remain paramount, underscoring the importance of expertise and innovation in the realm of machine waste handling.