Efficient Transport Solutions for Machine Chips on Automated Conveyor Systems

The Evolution of Machine Chip Conveyor Systems in Modern Manufacturing

In the ever-evolving landscape of modern manufacturing, efficiency and precision are paramount. Central to achieving these goals is the machine chip conveyor system, which plays a crucial role in managing the byproducts of machining processes. These systems are designed to streamline operations, enhance productivity, and maintain a clean working environment by efficiently transporting chip waste generated during machining activities.

Understanding Machine Chip Conveyors

At its core, a machine chip conveyor is an automated system that transports the metal shavings, chips, and other debris produced when machining materials such as metal, plastic, or composites. These chips, if not managed properly, can hinder production processes, damage machinery, and pose safety risks to workers. Therefore, having an effective chip removal system is essential in manufacturing facilities.

Types of Chip Conveyors

Machine chip conveyors come in various designs, each tailored to meet specific needs and applications. The most common types include

1. Drag Chains These systems utilize chains that drag the chips along a trough, ensuring efficient removal from the machine. They are ideal for heavy and abrasive materials, making them suitable for industries like aerospace and automotive.

2. Augers Screw conveyors or augers utilize a rotating screw blade to transport chips away from the workspace. They are particularly effective for bulk materials and are often used in locations with space constraints.

3. Magnetic Conveyors These systems use magnets to move ferrous materials away from machining areas. They are advantageous for their ability to handle materials without vacuum requirements and reduce the chance of contamination.

4. Wire Mesh Conveyors These are flexible and can handle a variety of chip sizes and shapes. They are commonly used in environments requiring versatility and easy maintenance.

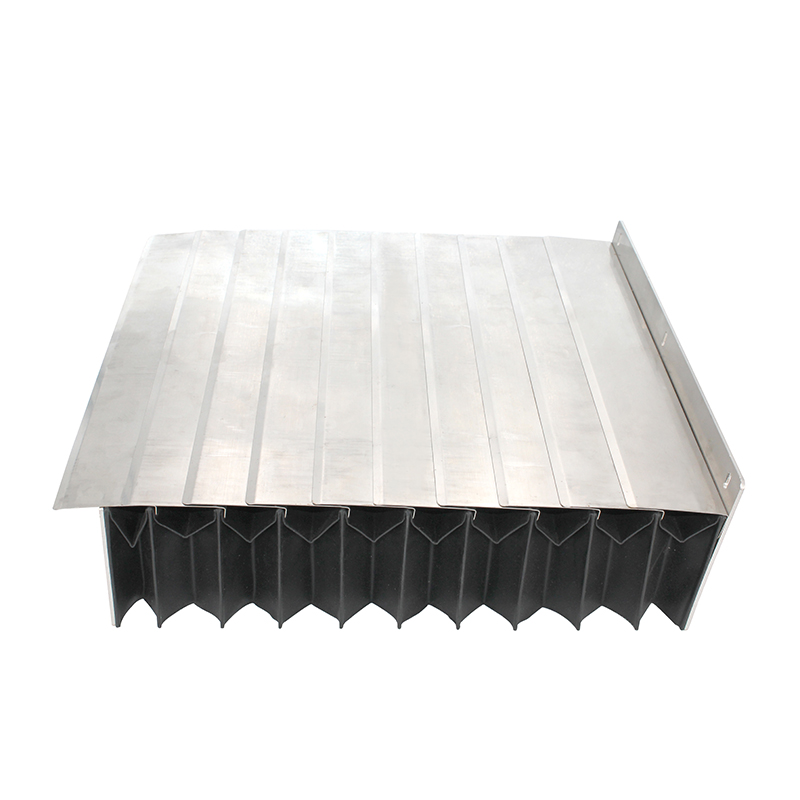

machine chip conveyor

Benefits of Machine Chip Conveyors

1. Increased Efficiency By automating the chip removal process, machine chip conveyors save significant time compared to manual handling. This allows operators to focus on machining, leading to improved productivity.

2. Enhanced Safety Accumulated chips and debris can create hazards on the shop floor. By using conveyors to keep these materials in check, companies can significantly reduce accidents, promoting a safer work environment.

3. Improved Machine Longevity Regular removal of chips prevents damage to machining tools and equipment. By ensuring that waste does not pile up, machine chip conveyors contribute to the longevity of manufacturing equipment and reduce maintenance costs.

4. Environmental Benefits Efficient chip management aids in recycling efforts, especially when dealing with metals. Many modern chip conveyors can separate and transport recyclable materials, thus supporting sustainable manufacturing practices.

The Future of Chip Conveyor Technology

As industries move towards Industry 4.0, the integration of smart technologies in machine chip conveyors is becoming increasingly common. Innovations such as IoT (Internet of Things) connectivity allow these systems to communicate with other machinery and production systems. This data exchange can monitor performance, predict maintenance needs, and optimize chip handling processes in real-time.

Additionally, advancements in materials science have led to the development of more robust and lightweight conveyor options. This not only enhances their durability but also allows for increased flexibility in layout and design.

Conclusion

In conclusion, machine chip conveyor systems are integral to the efficiency and safety of modern manufacturing operations. As technology continues to advance, these systems will likely become even more sophisticated, incorporating automation and data analytics to further enhance their performance. For manufacturers aiming to improve operational efficiencies and maintain a clean workspace, investing in the latest chip conveyor technology is not just a choice—it's a necessity in today’s competitive landscape. Through continuous innovation and adaptation, machine chip conveyors will play an essential role in shaping the future of manufacturing.